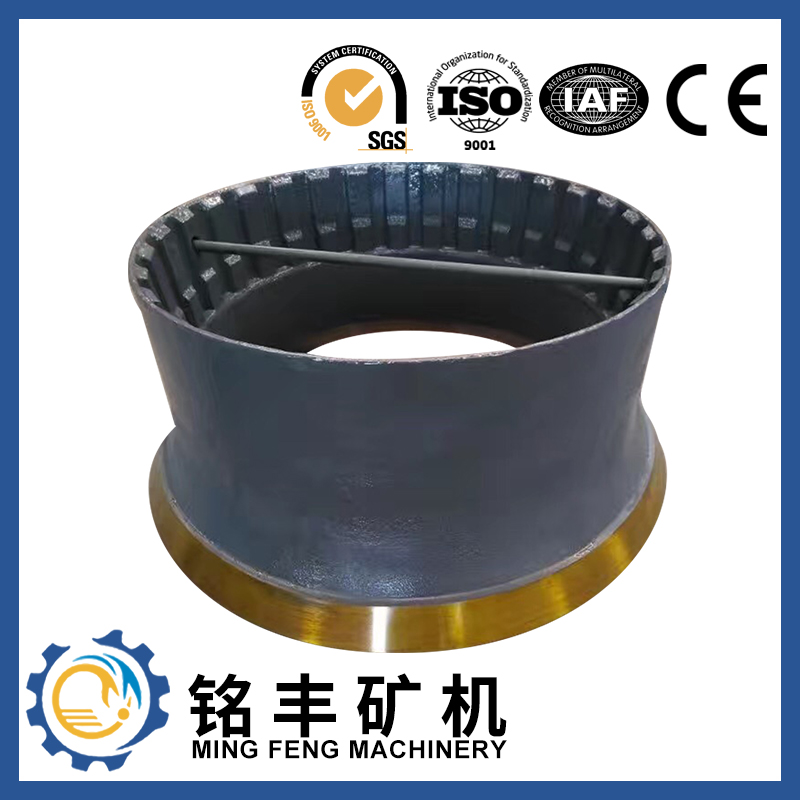

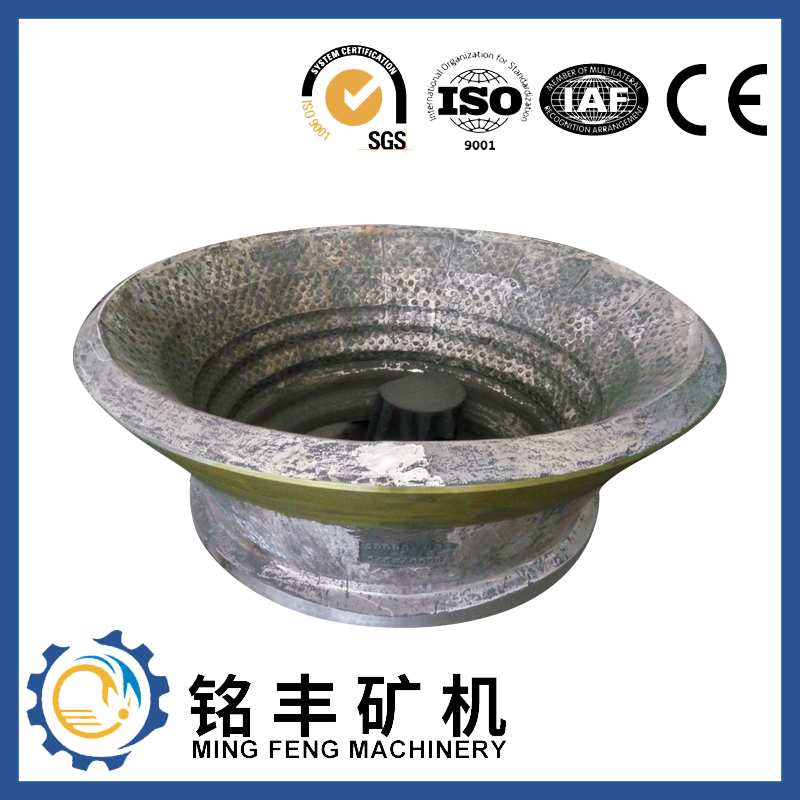

Wholesale Mn22cr2 Broken Wall - TIC insert cone liner & bowl liner – MING FENG MACHINERY

Wholesale Mn22cr2 Broken Wall - TIC insert cone liner & bowl liner – MING FENG MACHINERY Detail:

Description:

When Cone crusher works, eccentric sleeve rotates by motor through V-belt, big pulley, drive shaft, a small bevel gear, big bevel gear. crushing cone axis rotates and swing under the pressure of eccentric sleeve, make the cone sometime close to the mantle and sometimes far from it, so that the material in the ring fixed cone and fixed cone crushing cavity composed constantly under attack, squeezing and bending and breaking. After several extrusion, impact and bending, the material is crushed to the required size, and discharged from the lower part.

Benefits:

Increased Wear Life – MF Machinery’s unique TiC insert cone liners and bowl liners design features a strengthened high-wear zone for maximum usable wear life and reduced breakage.

Strengthens as It Works – Concaves and mantles body are cast in durable manganese steel (Mn18Cr2) that gets harder the longer you work it.

Consistent Wear – More consistent wear profile for uniform product output and increased efficiency.

Titanium Carbides – TiC inserts currently available are 20mm, 40mm, 60mm, and 80mm depths.

Fewer Change-Outs – Greater durability and longer wear life means fewer change outs, more up-time, and lower maintenance costs

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We normally follow the basic principle Quality Initial, Prestige Supreme. We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for Wholesale Mn22cr2 Broken Wall - TIC insert cone liner & bowl liner – MING FENG MACHINERY , The product will supply to all over the world, such as: Gambia, India, Germany, We insist on the principle of Credit being primary, Customers being the king and Quality being the best, we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed