Top Suppliers Apsm-1515 Wear Parts - HPC-400 hydraulic cone crusher – MING FENG MACHINERY

Top Suppliers Apsm-1515 Wear Parts - HPC-400 hydraulic cone crusher – MING FENG MACHINERY Detail:

Hydraulic Cone Crusher Technical Data:

|

Model |

Cavity |

Min.discharge size |

Inch |

Capacity |

Motor power |

Weight |

Dia.movable cone |

|

HPC-400 |

C |

13 |

320 |

230-700 |

400 |

33 |

1500 |

|

F |

6 |

110 |

145-430 |

Description:

The hydraulic cone crusher consists of the base, the eccentric sleeve, the transmission shaft, the fixed cone, the mobile cone, the feed opening and the hydraulic system.

Based on years of experience in manufacturing crushers, the hydraulic cone crusher manufactured by our company has introduced advanced technologies abroad Compared with ordinary crushers, this crusher has a high crushing capacity and efficiency. Iron can pass through the crushing chamber with the dual channels that is controlled by the hydraulic system. Unlike the spring cone crusher which has to stop for maintenance when the machine stops working suddenly, this crusher does not need to in the case because the material will be discharged with the help of the hydraulic system.

Working Principle:

During operation, the motor drives the sleeve to rotate through the belt wheel or coupling. Under the force of the rotating sleeve, the transmission shaft and the cone swing periodically, which makes the surface of the cone come near to the surface of the mantle periodically. The material is crushed and discharged during the process.

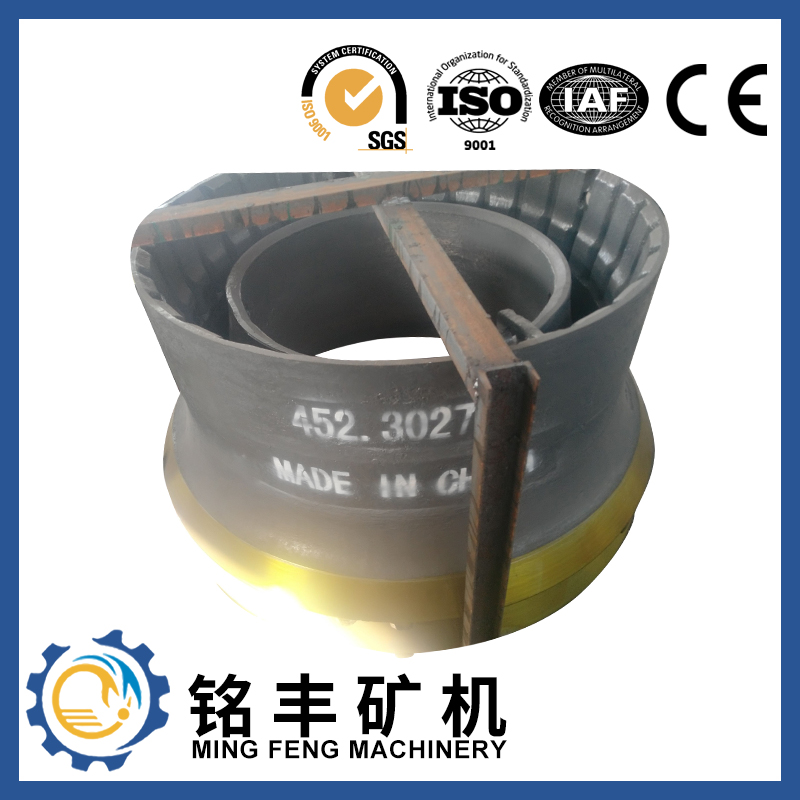

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We usually keep on with the principle Quality To start with, Prestige Supreme. We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for Top Suppliers Apsm-1515 Wear Parts - HPC-400 hydraulic cone crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Jordan, Indonesia, Romania, Taking the core concept of to be the Responsible. We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed