Top Quality Jaw Crusher Uk - PF-1515V impact crusher – MING FENG MACHINERY

Top Quality Jaw Crusher Uk - PF-1515V impact crusher – MING FENG MACHINERY Detail:

Impact Crusher Technical Data:

|

Model |

Spec of Rotor |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Motor Power |

Weight |

Overall Dimensions |

|

PF-1515V |

Φ1500×1500 |

850×1580 |

350 |

220-280 |

280-315 |

29.5 |

3550×2835×3270 |

Description:

Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher.

Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each other.

Advantages:

1.With large feed opening and deep crushing chamber, it can deal with materials with high hardness and big size, but produces less powder.

2.Products in various sizes can be obtained by adjusting the distance between plate and the rotor.

3.Compact structure, newly-designed impact plate welded on the rotor with high inertial force

4.By adjusting the distance between plates, products in various sizes and fine shape can be obtained.

5.Non-key connection: easy to operate and cost-effective

6.Wide range of applications.

7.High productivity and overall efficiency

8.Durable and heavy-duty plates.

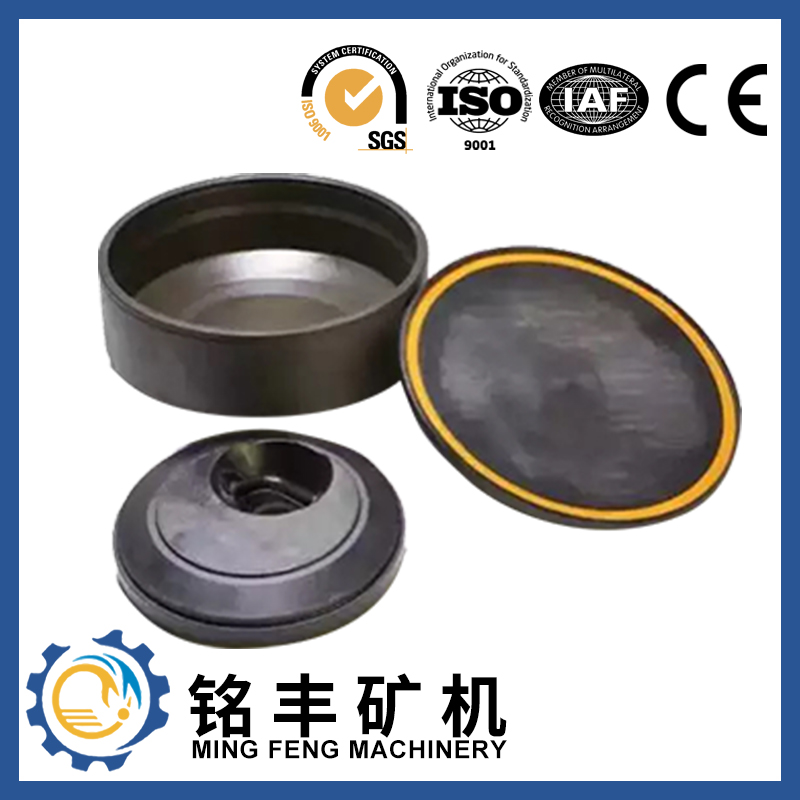

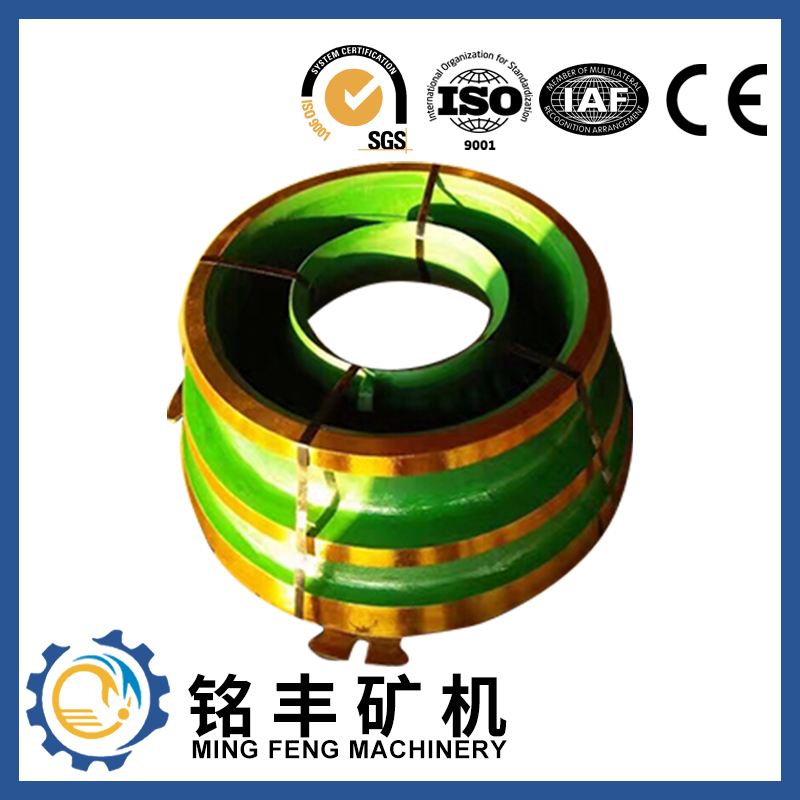

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for Top Quality Jaw Crusher Uk - PF-1515V impact crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Japan, Greek, Manchester, Our company always provides good quality and reasonable price for our customers. In our efforts, we already have many shops in Guangzhou and our products have won praise from customers worldwide. Our mission has always been simple: To delight our customers with best quality hair products and deliver on time. Welcome new and old customers to contact us for the future long term business relationships.

This company has the idea of better quality, lower processing costs, prices are more reasonable, so they have competitive product quality and price, that's the main reason we chose to cooperate.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed