Supply OEM China High Efficiency and Energy-Saving Wet Diamond Mining Equipment Ball Mill

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for Supply OEM China High Efficiency and Energy-Saving Wet Diamond Mining Equipment Ball Mill, We have now experienced manufacturing facilities with a lot more than 100 workforce. So we could guarantee short lead time and top quality assurance.

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for Aluminium Ball Mill, China Grinding Mill, Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

Overview:

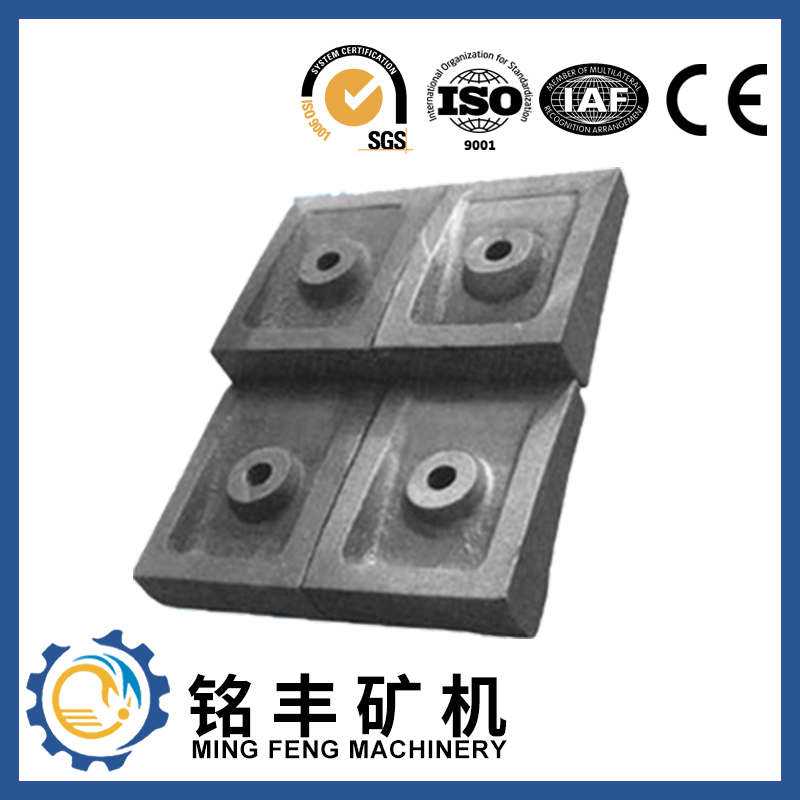

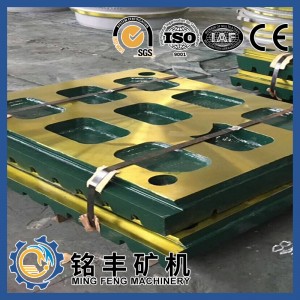

| Type | Crusher liner board, lining plate | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Grinding ores | Quartz, Gold ore, Cement clinker, etc. |

| Machine Type | Ball Mill Liner | Certification | ISO 9001:2008 |

| Main Materials | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

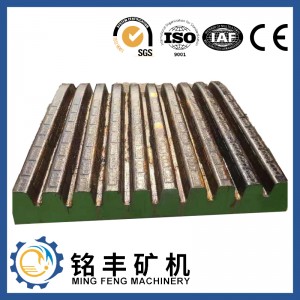

The main function of ball mill liner is to protect the ball mill main partsfree from abrasion, the most important requirement for the material is the feature of good wear-resistance and high toughness. The material high manganese steel with enough toughness, and it will become cold-hardening with some extent impact,that will make the material better on hardness and wear-resistance, so it is used as the widely used material for liners.

We can manufacture all kinds of wear parts of crusher according to customers’ requirements and drawings. If you are interested in our products and want to know information from us please feel free to contact us

Features:

1. Low-weight, high-strength designs create less stress on mill bearings and reduced torque requirementsExcellent sealing

2. properties eliminate mineral lock-up, improving the recovery of valuable products

3. Blinding of grate plates is virtually eliminated, increasing throughput

4. Low liner weight enables safe installation by hand. No mill liner handler required!

5. Low noise levels enhance working conditions

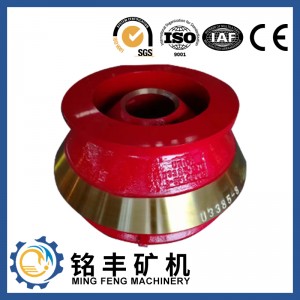

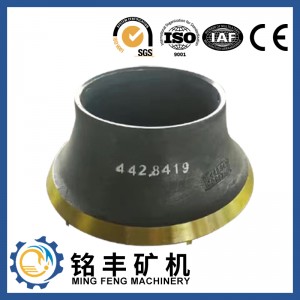

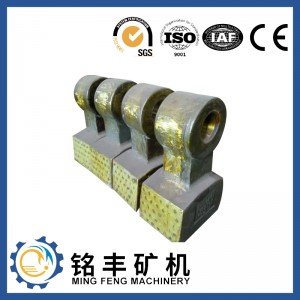

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for Supply OEM China High Efficiency and Energy-Saving Wet Diamond Mining Equipment Ball Mill, We have now experienced manufacturing facilities with a lot more than 100 workforce. So we could guarantee short lead time and top quality assurance.

Supply OEM China Grinding Mill, Aluminium Ball Mill, Ensuring high product quality by choosing the best suppliers, now we have also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed