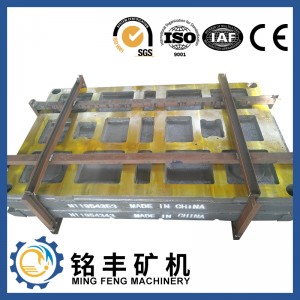

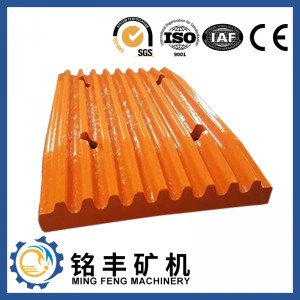

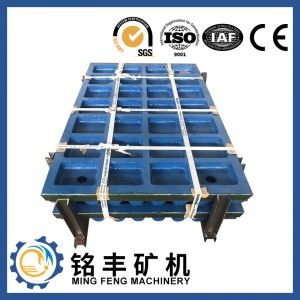

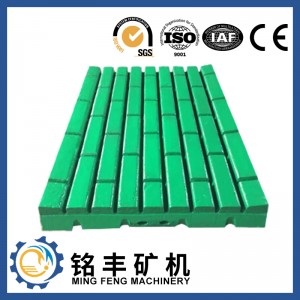

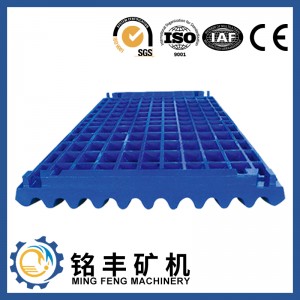

Steel sand casting parts in quarry mining stone plant

1. Material: High manganese steel, alloy steel.

2. Moulding processing: Sand casting or lost foam casting

3. Melting facilities: Medium frequency electric induction furnace/electric arc furnace.

4. Casting Inspection: Direct-reading spectrum instrument, metallographic analysis, ultrasonic inspection, magnetic particle inspection, mechanical properties inspection.

5. Heat treatment facilities: Special heating electric furnaces, special water pools etc special quenching equipments.

6. Surface treatment: Shot blast cleaning.

7. Industrial categories: Construction engineering machine industry, mineral processing, recycling industry, structural shredder parts, general machinery industry, dredging vessel, engineering ship industry and others.

8. User-friendly, easy to disassembly and assembly

| High Manganese Casting Material Chemical Composition | |||||||

| Code Elem. | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

Advantages:

1. Top continuous crushing performance.

2. Low cost per crushed ton by increased wear life.

3. Increased production time due to reduced downtime.

4. Increased safety because of less wear part change-outs.

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed