Short Lead Time for Jaw Crusher Videos - 2PG-750X500 roll crusher – MING FENG MACHINERY

Short Lead Time for Jaw Crusher Videos - 2PG-750X500 roll crusher – MING FENG MACHINERY Detail:

|

Specification |

Max Feed Edge |

Discharge Size |

Production |

Power |

Weight |

|

2PG-750X500 |

≤40 |

2–20 |

15-40 |

37 |

12250 |

Description:

The double-roller crusher is one of the crushers produced by our company for coarse/fine crushing. It is widely used in fields of cement making, chemical engineering, waterpower, metallurgy, construction, fire-proof material making, etc. It is suitable to deal with medium-hardness materials like limestone, pebble, clinker, coke, etc. The material to be crushed should have fracture strength less than 300MPa and humidity less than 35%.

Working principle:

During operation, the two rollers, driven by the motor through the V-belt, rotate in the opposite direction. The material will be crushed by the rollers after passing the feed opening and then be discharged from the base. The wedge-shaped device or washer between the rollers is adjustable. At the top of the wedge-shaped device, there is a bolt for adjusting. When the wedge-shaped device is pulled up by the bolt, the rollers will leave the fixed wheel. In the case, particles obtained become larger. While the wedge-shaped device moves downwards, the distance between the rollers becomes short under the influence of pressed springs. In the case, particles obtained become smaller. By increasing/decreasing the number or thickness of the washer, larger/smaller particles can also be obtained.

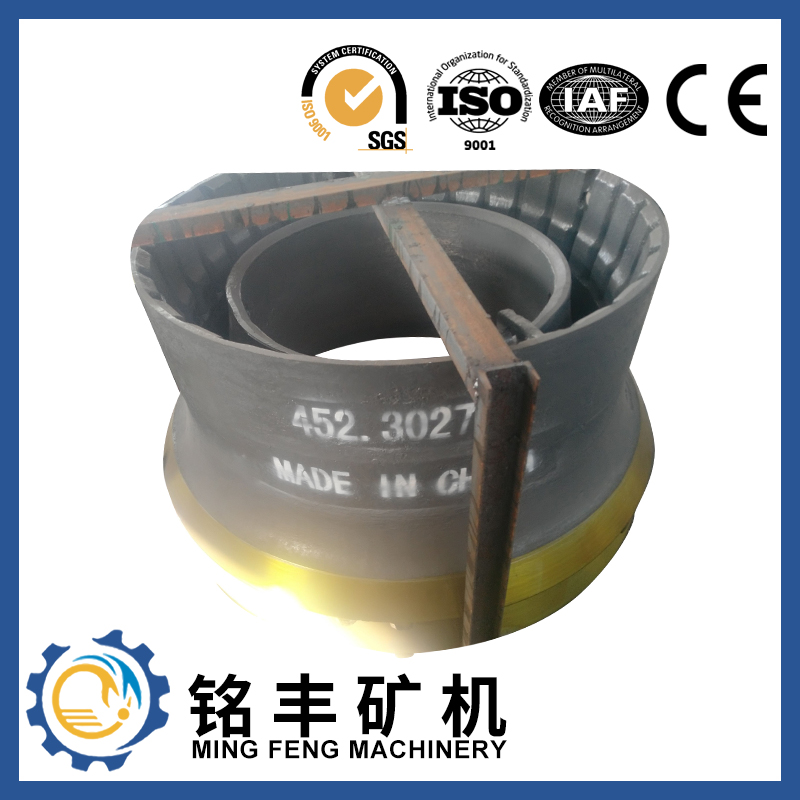

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Short Lead Time for Jaw Crusher Videos - 2PG-750X500 roll crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Greenland, Swaziland, UK, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we've got better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We have been always here working for your demands whenever you require.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed