Roll crusher roll high manganese steel roller

Overview:

| Type | tooth plate, Double Roller Crusherroller skin, high manganese steel roller skin | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Roller Crusher | Certification | ISO 9001:2008 |

| Hardness | HRC58 – HRC63 | Production Capability | More than 30000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Production Test | Hardness testing, metallographic testing, spectral analysis, mechanical properties and heat treatment. | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

We can provide wearing parts (such as roller sleeve)for various models roller crushers. And we can also manufacture products with different materials according to the drawings supplied by our customers.

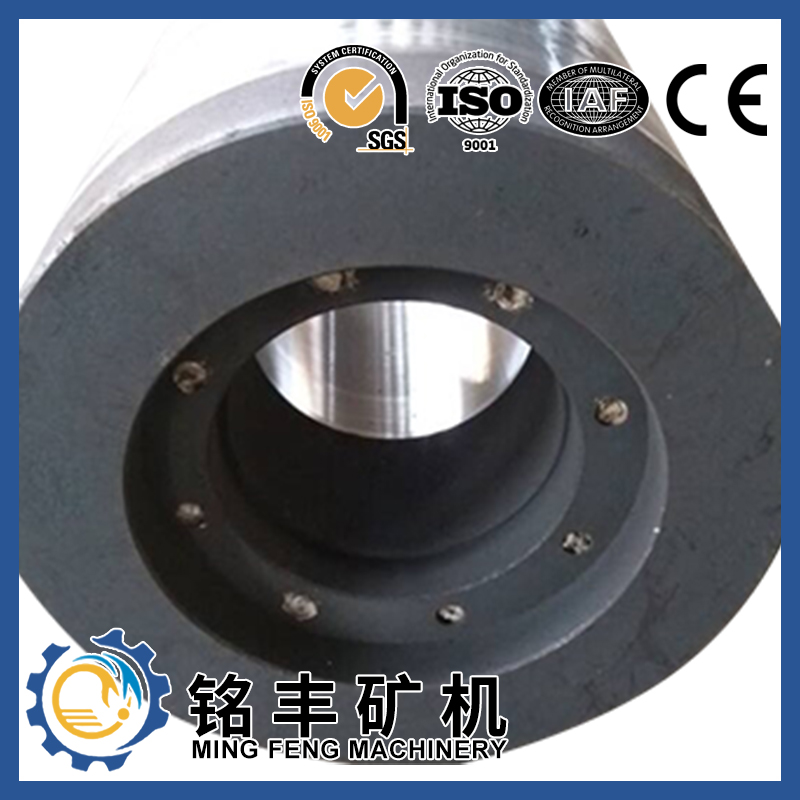

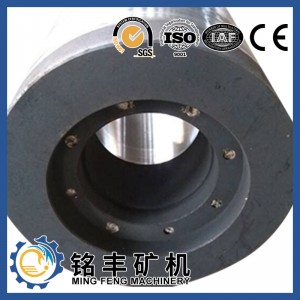

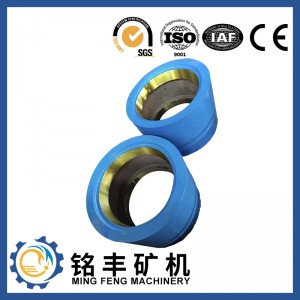

High manganese steel roller skin

Roll Crusher high manganese steel roller skin roller optimized heat treatment process, water toughening treatment carried out. Super Paper roll (roller) after water toughening treatment temperature is not lower than 1040 ℃, the microstructure of austenite and carbide (trace), optimized heat treatment process to make products uniform hardness, excellent resistance to mechanical shock, thermal shock, anti-wear properties.

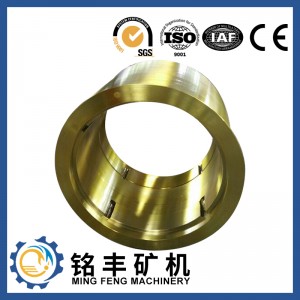

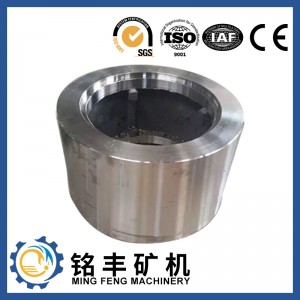

High chromium compound roll skin

Such roller outer skin made of high-chromium alloy, ductile iron lining, high surface hardness, is mainly used for crushing roller machine used in ceramic tiles scission, coal gangue, shale, brick industrial process tailings fineness checks while rolling through the mixing of raw materials, increased formability, and lower raw material of plastic or clay hollow bricks high porosity needed raw materials for fine processing applications. Select the device should be equipped with a roll grinder ring to ensure proper function and play its role.

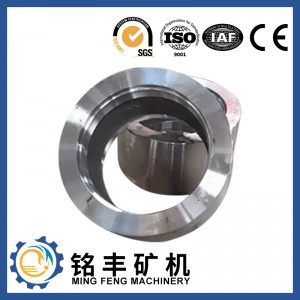

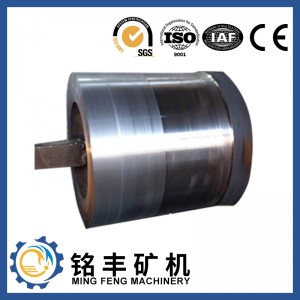

Multi roll leather wear-resistant alloy

Such roll skin is China in the late 20th century combined with national conditions was developed on the basis of the introduction of digestion. Its success is by quenching make the surface hardness of HRC50-55. Such roll skin can be used to check the fineness of the raw material hardness lower case and plasticizing functions, such as high fly ash, soft shale, coal gangue and dry soil condition stiff raw materials containing stone.

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed