Reasonable price Jaw Crusher Notes - PEX-250×750 jaw crusher – MING FENG MACHINERY

Reasonable price Jaw Crusher Notes - PEX-250×750 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PEX-250×750 |

250×750 |

210 |

8-22 |

330 |

22 |

25-60 |

4.9 |

Description:

This jaw crusher uses motor as its power. Through the motor’s wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and discharged through the discharging opening.

It can be used to crush rocks with a fracture strength within 147-245MPa into coarse/medium/fine size. In order to meet the requirement of high crushing ratio and hardness of low carbon ferrochrome in fields of metallurgy, mining and construction nowadays, we have designed modern Jaw crusher.

Advantages:

1. Rigid one-piece fabricated base frame is reinforced for unmatched durability and strength

2. Massive cast steel pitman is heavily reinforced to provide the ability to absorb the shock loads

3. Deep crushing chambers and large eccentric shafts offset combined with a steep toggle angle yield more compressive force throughout the crushing chamber

4. Large balanced flywheels supply continuous inertia to the crushing action

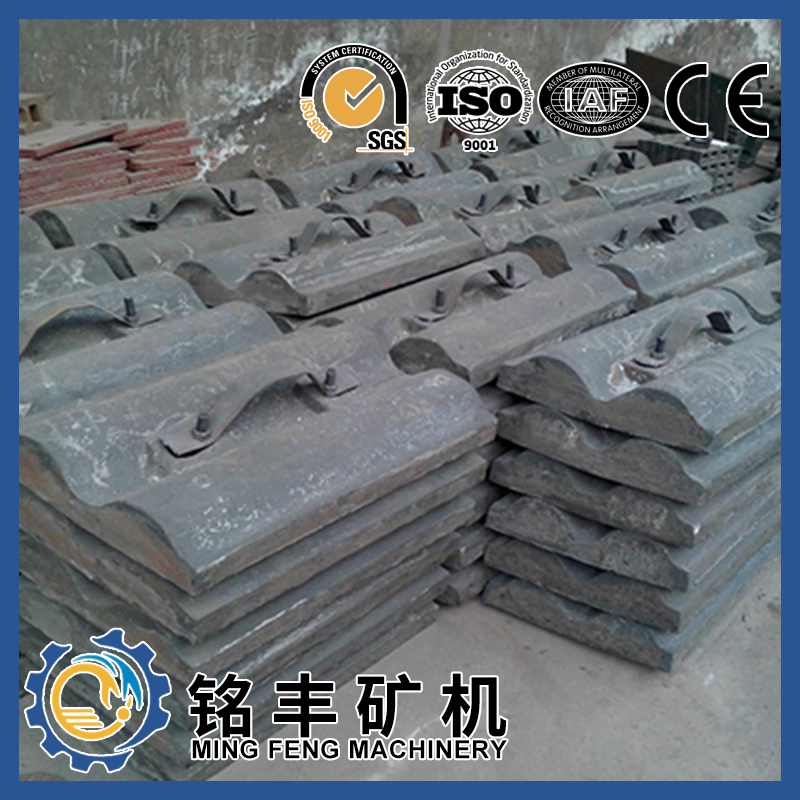

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Reasonable price Jaw Crusher Notes - PEX-250×750 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Iceland, Bolivia, Turkey, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed