Quality Inspection for Mp1250 Broken Wall - HPC-160 hydraulic cone crusher – MING FENG MACHINERY

Quality Inspection for Mp1250 Broken Wall - HPC-160 hydraulic cone crusher – MING FENG MACHINERY Detail:

Hydraulic Cone Crusher Technical Data:

|

Model |

Cavity |

Min.discharge size |

Inch |

Capacity |

Motor power |

Weight |

Dia.movable cone |

|

HPC-160 |

C |

13 |

150 |

120-240 |

160 |

13 |

950 |

|

F |

6 |

76 |

55-180 |

Description:

Hydraulic cone crusher with high-efficiency and hydraulic pressure was widely used in mining, concrete factory, sandstone making, etc. The machinery’s pressure resistance strength is under 350Mpa. And they are widely suitable for primary crushing of many kinds of mining and rock such as many kinds of ores, concrete, fireproof material, bauxite, quartzite, corundum, perlite, ironstone, basalt, etc.

Cone crusher consist of frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. During operation, the motor drives the eccentric shaft shell to turn around through ahorizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

Advantages:

1. Large reduction ratio, high production efficiency;

2. Less consumption of wearing parts, low operating costs;

3. Pyramid broken, perfect of product shape;

4. Hydraulic protection and hydraulic pressure cavity clear high degree of automation to reduce downtime;

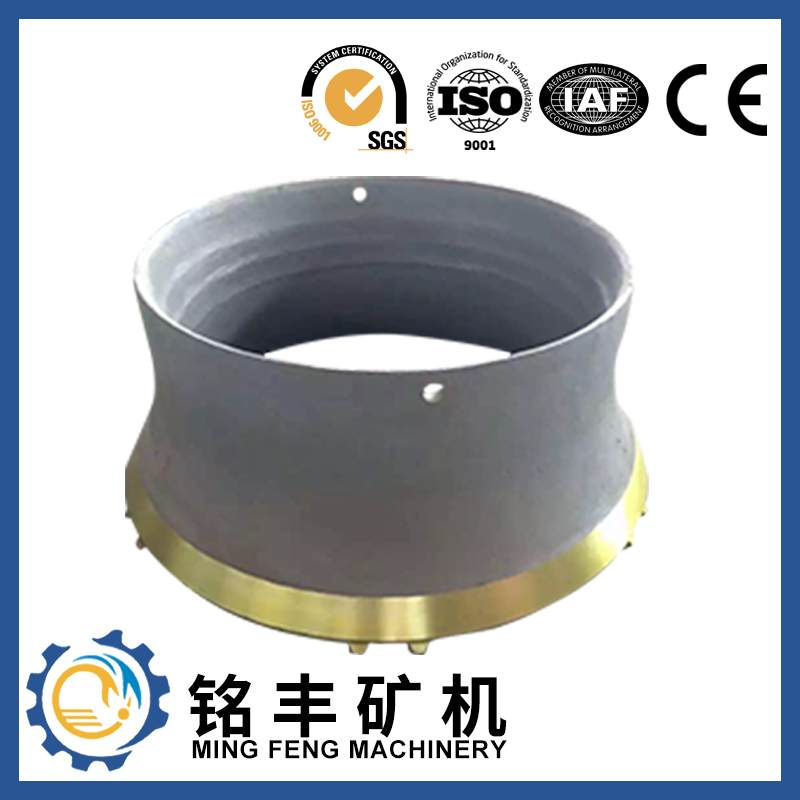

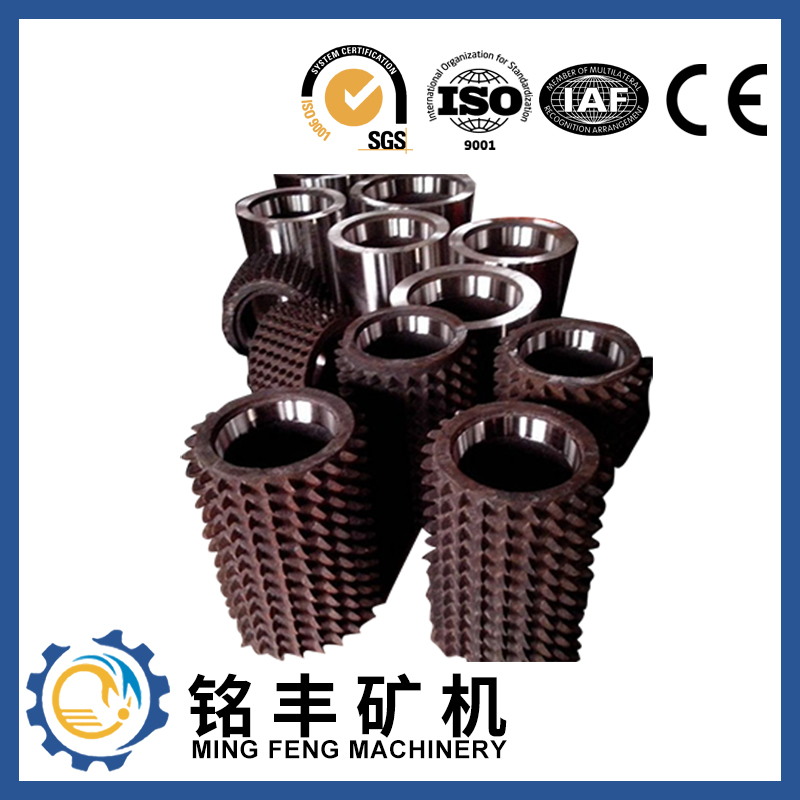

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Quality Inspection for Mp1250 Broken Wall - HPC-160 hydraulic cone crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Cologne, Cologne, panama, Nowadays our merchandise sell all over the domestic and abroad thanks for the regular and new customers support. We supply high quality product and competitive price, welcome the regular and new customers cooperate with us!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed