professional factory for Mining Heavy Equipment And Machine - YDSPS-100 mobile crusher – MING FENG MACHINERY

professional factory for Mining Heavy Equipment And Machine - YDSPS-100 mobile crusher – MING FENG MACHINERY Detail:

|

Model |

YDSPS-100 |

|

|

Capacity(t/h) |

100 |

|

|

Max Feeder(mm) |

500 |

|

|

Hopper(m3) |

12 |

|

|

1#frame |

Feeder |

ZSW-380×96 |

|

Jaw Crusher |

PE-600×900 |

|

|

Frame size |

12894×2574×4078 |

|

|

2#frame |

Cone crusher |

PYB-1200 |

|

Impact crusher |

Null |

|

|

Frame size |

12400×2500×4189 |

|

|

3#frame |

vibrating screen |

3YA-1548 |

|

Frame size |

8640×2500×4046 |

|

Description:

Compositions:

The mobile crushing plant consists of the vibrating feeder, the jaw crusher, the impact crusher, the cone crusher, the sand-making machine, the belt conveyor and the vibrating screen. (The machine can be customized).

Advantages:

1.Mobility: The plant can be extended according to the location of the resource or the construction, and be equipped with devices according to your various requirements. It can move smoothly on complex roads.

2.Integral structure: The equipment becomes easier to operate and more energy is saved.

3.Flexibility and adaptability: Each device can work separately.

4.Stability: These are the most advanced crushing and screening devices.

5.Time and energy saving: The material can be crushed at the spot.

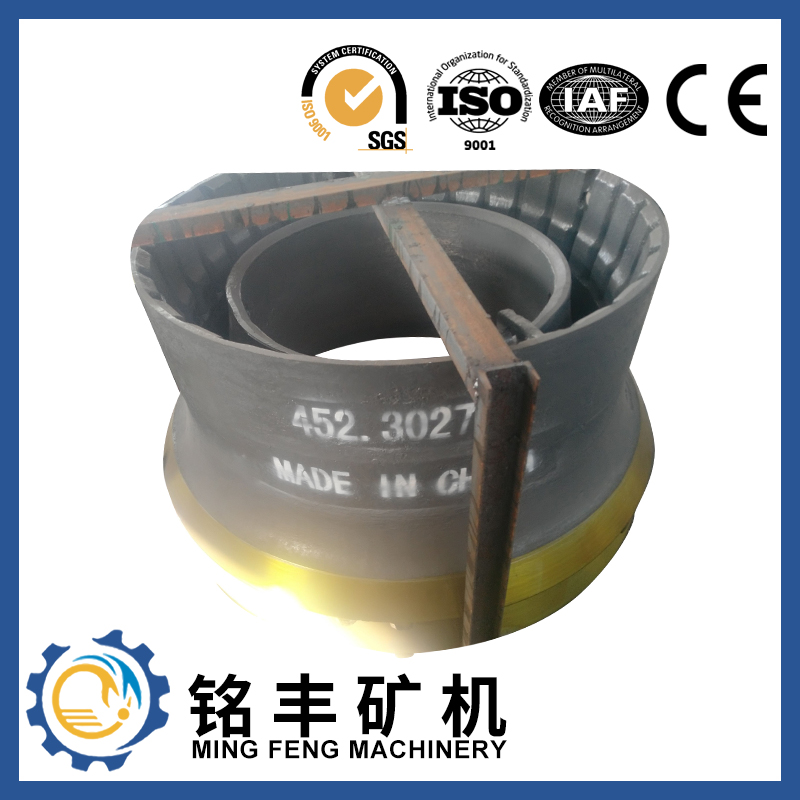

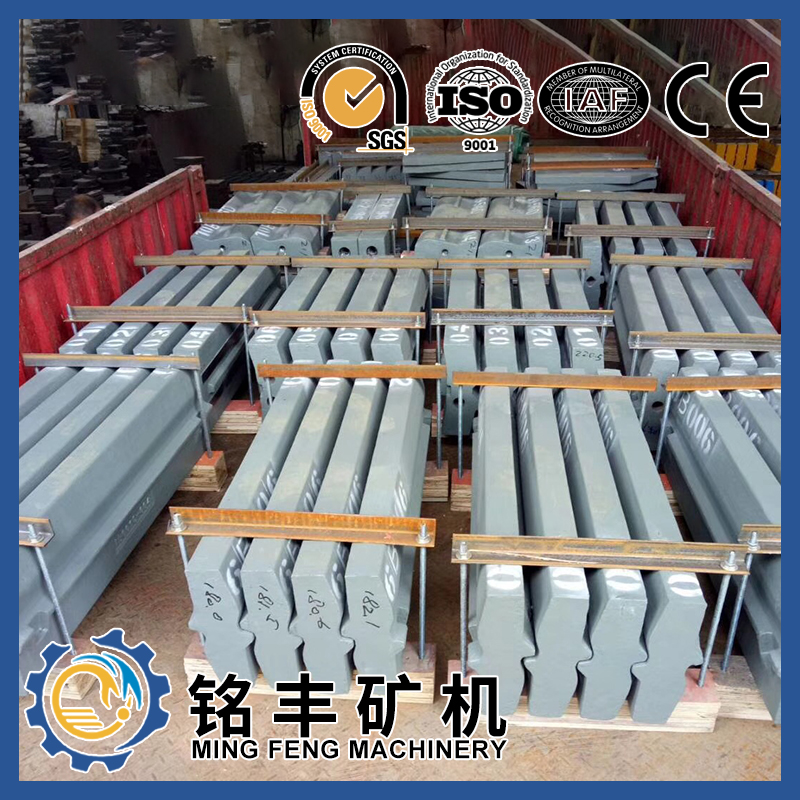

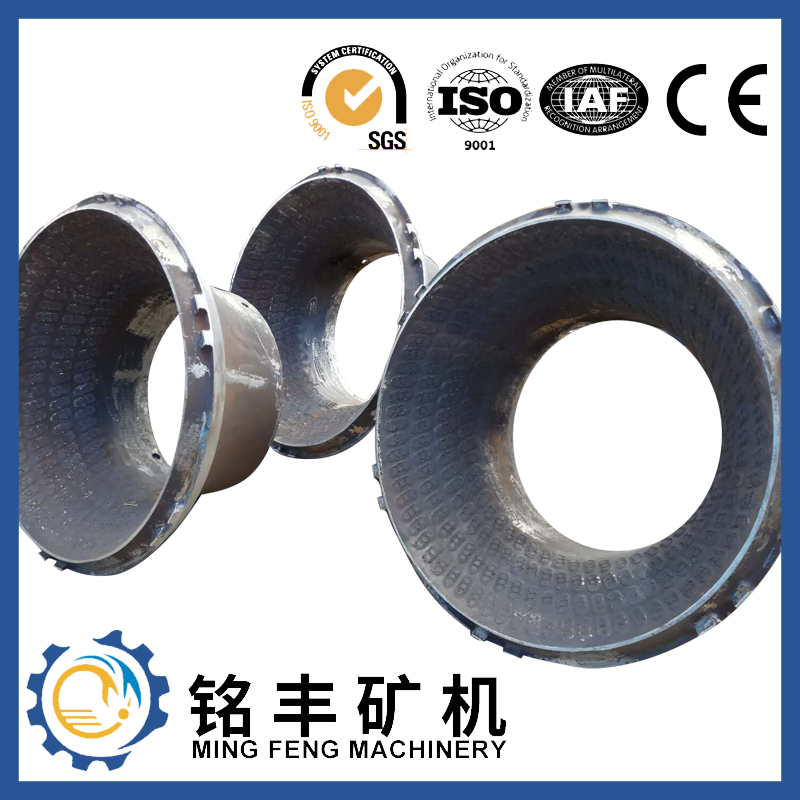

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for professional factory for Mining Heavy Equipment And Machine - YDSPS-100 mobile crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Southampton, Jersey, Islamabad, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed