Professional China High Chromium Double Roller - High quality grinding roller for roller crusher spare parts – MING FENG MACHINERY

Professional China High Chromium Double Roller - High quality grinding roller for roller crusher spare parts – MING FENG MACHINERY Detail:

Overview:

| Type | tooth plate, Double Roller Crusherroller skin, high manganese steel roller skin | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Roller Crusher | Certification | ISO 9001:2008 |

| Hardness | HRC58 – HRC63 | Production Capability | More than 30000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Production Test | Hardness testing, metallographic testing, spectral analysis, mechanical properties and heat treatment. | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

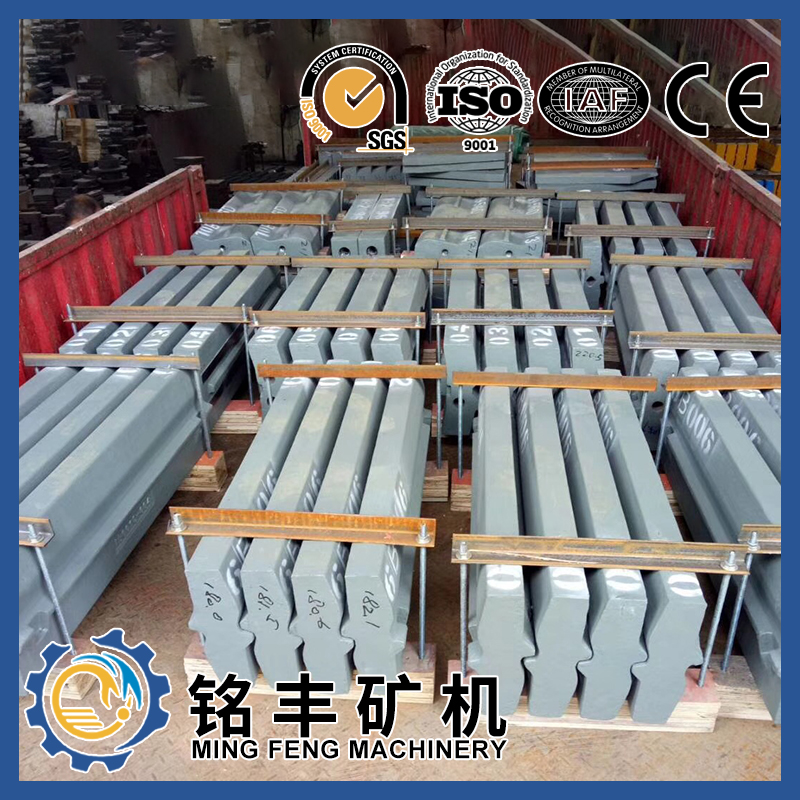

High manganese steel roller skin

Roll Crusher high manganese steel roller skin roller optimized heat treatment process, water toughening treatment carried out. Super Paper roll (roller) after water toughening treatment temperature is not lower than 1040 ℃, the microstructure of austenite and carbide (trace), optimized heat treatment process to make products uniform hardness, excellent resistance to mechanical shock, thermal shock, anti-wear properties.

Our advantage:

High Manganese Casting wear parts processed by our foundry, using special heat-treatment process. It has a service life 10% longer than those made of traditional high manganese steel. Our products with good performance in different working condition can greatly decrease the time of examination & repair and the use-cost.

| High Manganess Casting Material Chemical Composition | |||||||

| Code Elem. | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

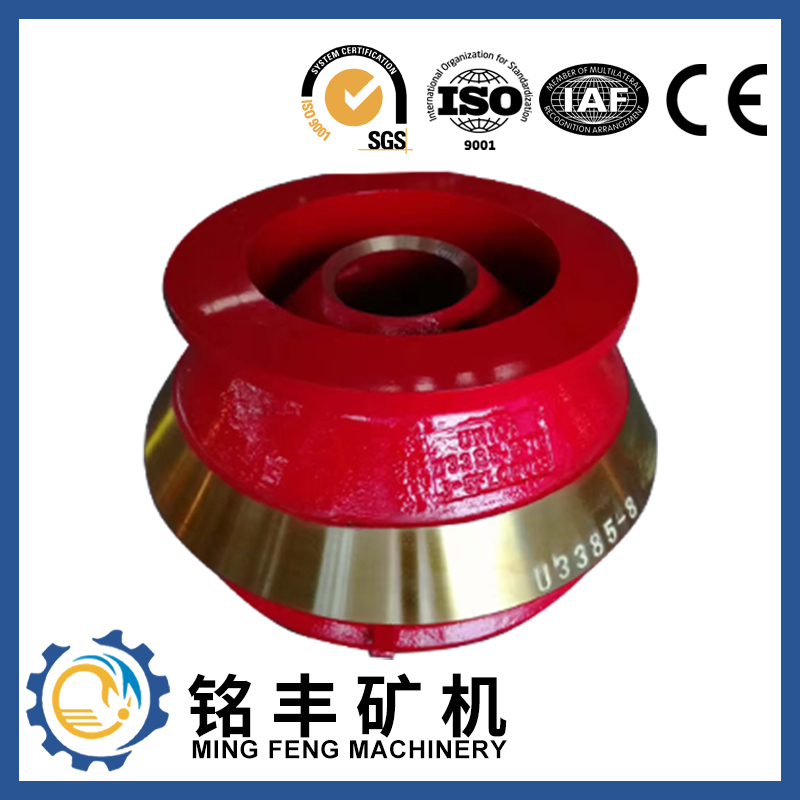

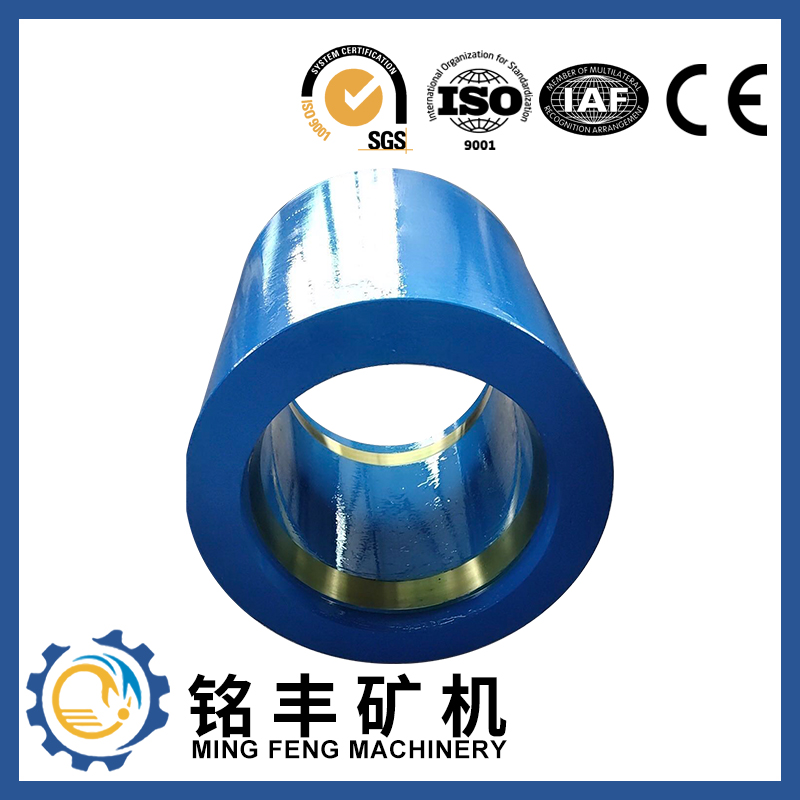

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

So that you can finest fulfill client's demands, all of our operations are strictly performed in line with our motto High Excellent, Competitive Price, Fast Service for Professional China High Chromium Double Roller - High quality grinding roller for roller crusher spare parts – MING FENG MACHINERY , The product will supply to all over the world, such as: panama, Romania, Netherlands, Our company upholds the spirit of innovation, harmony, team work and sharing, trails, pragmatic progress. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed