PriceList for Rod Mill Architect - Durable ball mill liners plate for ball mill – MING FENG MACHINERY

PriceList for Rod Mill Architect - Durable ball mill liners plate for ball mill – MING FENG MACHINERY Detail:

Overview:

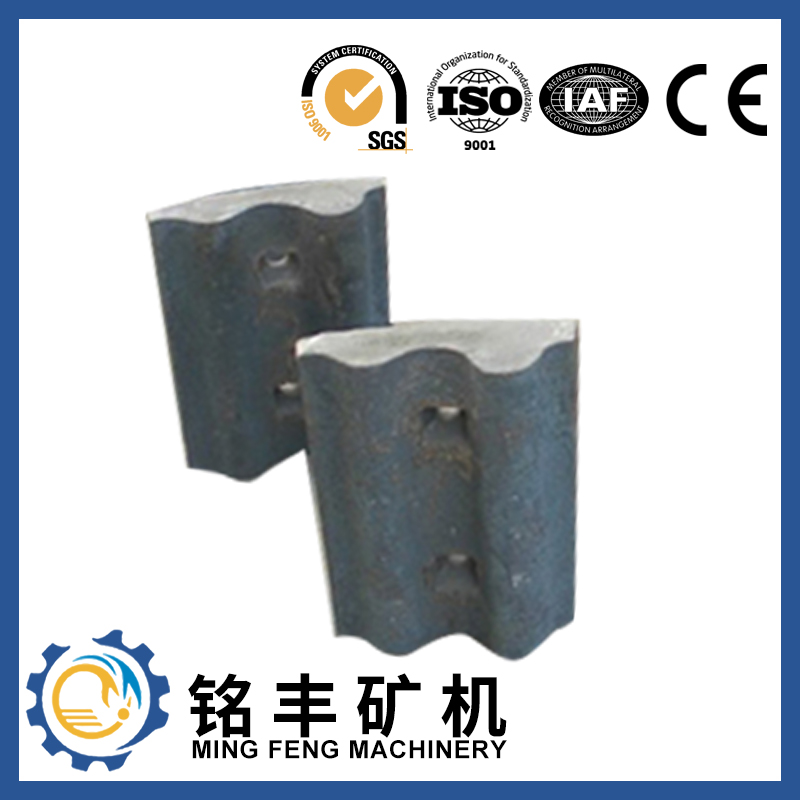

| Type | Crusher liner board, lining plate | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Ball Mill Liner | Certification | ISO 9001:2008 |

| Main Materials | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

The main function of ball mill liner is to protect the ball mill main partsfree from abrasion, the most important requirement for the material is the feature of good wear-resistance and high toughness. The

material high manganese steel with enough toughness, and it will become cold-hardening with some extent impact,that will make the material better on hardness and wear-resistance, so it is used as the

widely used material for liners.

Advantages:

1. Speed up the flow rate of the materials.

2. Grinding machine noise is reduced 5-10 db.

3. The equipment-hour yield of ball grinding mill could improve 10-30%.

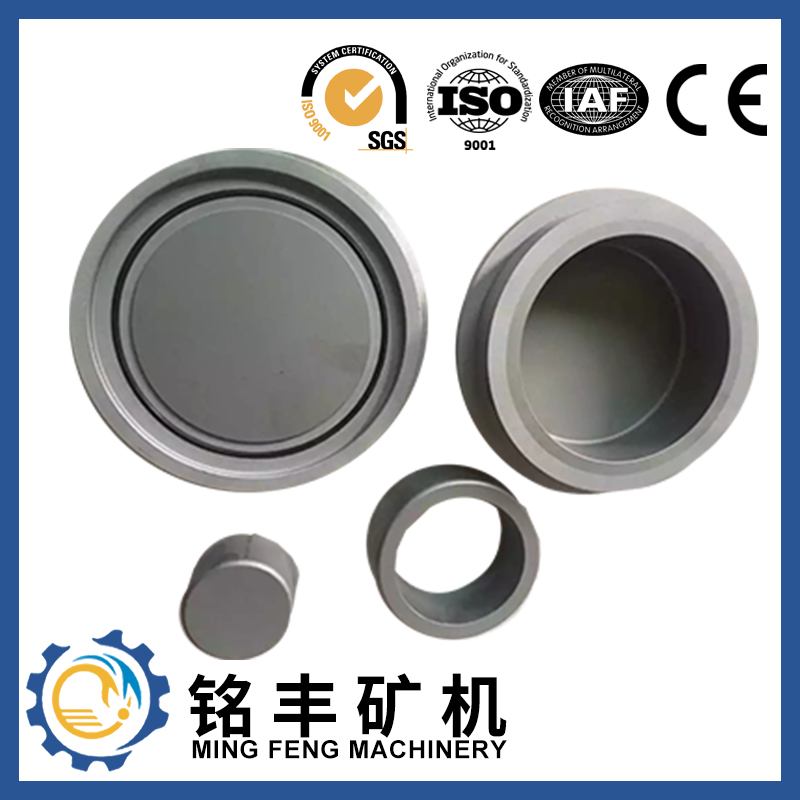

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for PriceList for Rod Mill Architect - Durable ball mill liners plate for ball mill – MING FENG MACHINERY , The product will supply to all over the world, such as: Guatemala, Juventus, Guatemala, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed