PriceList for Hammer Crusher Design - Mn13Cr2 hammer with carbide tip – MING FENG MACHINERY

PriceList for Hammer Crusher Design - Mn13Cr2 hammer with carbide tip – MING FENG MACHINERY Detail:

Overview:

| Place of Origin | Hunan, China | Content of Mn | 26% |

| Product name | Hammer | Machine Type | Crusher |

| Material | hard metal; carbide; cemented carbide; kentanium; wimet; sintered-carbide; hard alloy; carbide alloy Cr20Mn2,Cr26Mn2 | ||

| Processing Type | Casting | Application | Ore Mining |

| Certification | ISO9001 | Testing Method | Hardness test and flaw detector test |

| Control | Spectrometer chemical analysis and control while producing | ||

Description:

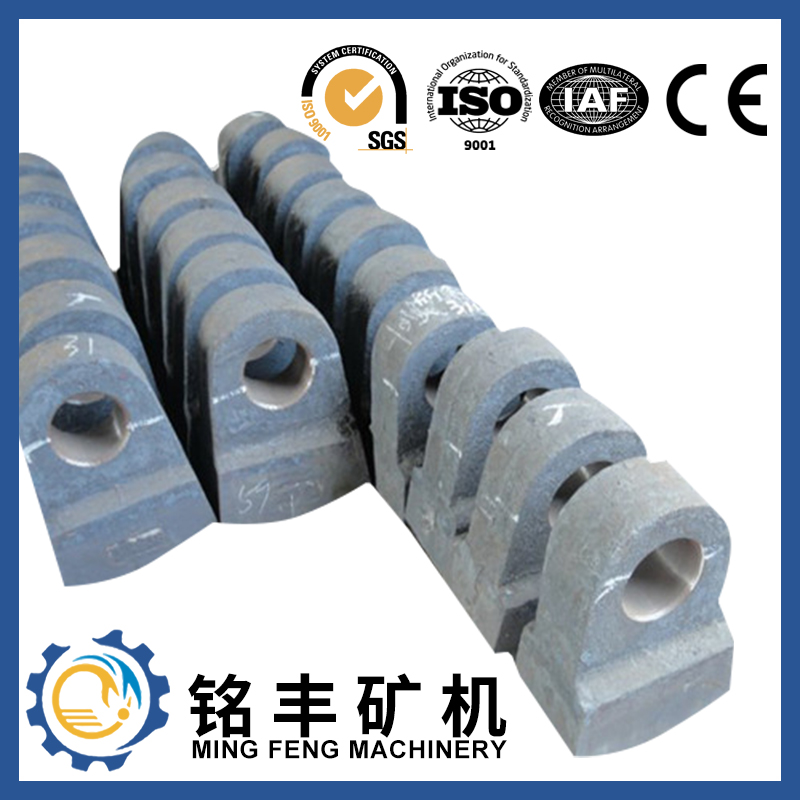

This kind of hammers have a service life 50% longer than those made of common high manganese steel and is safer to use. Crusher hammers aim at the crushing of limestone with abnormal content of SiO2.

During Hammer crusher parts operation, The rotor is driven by the motor to move, and the rotor drives the crusher hammer board to rotate at a high speed, thus the materials crushed in the crushing cavity by the rotating crusher hammer board. The end product comes out of the machine via the strips of screen. The size of the granularity can be adjusted by changing the space among the screen strips.

Hammer crusher parts is widely applied in mining, metallurgy, construction, road building, chemical and phosphatic industry, and is suitable for hard and mid-hard rocks and ores.

Advantages:

1. Using heat treatment process and water toughening technology.

2. Molten steel is purer and the matrix is more compact.

3. Applying the method of alloying and modification treatment of rare earth, and optimizing the matching of chemical composition.

4. Crusher hammers casted the Tungsten Titanium alloy in the high-manganese steel substrate, It may resist the severe grinding abrasion.

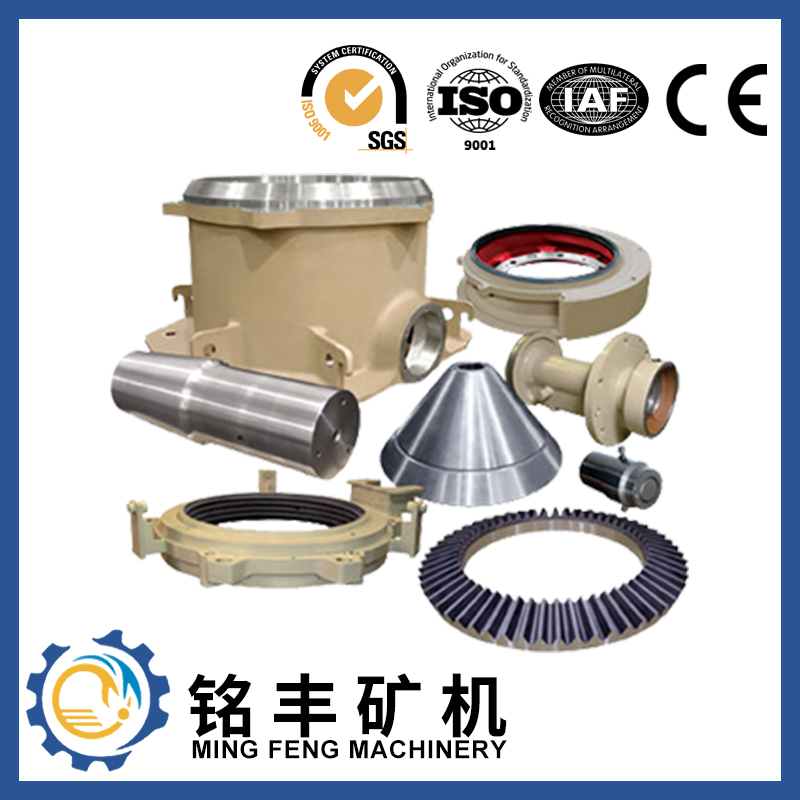

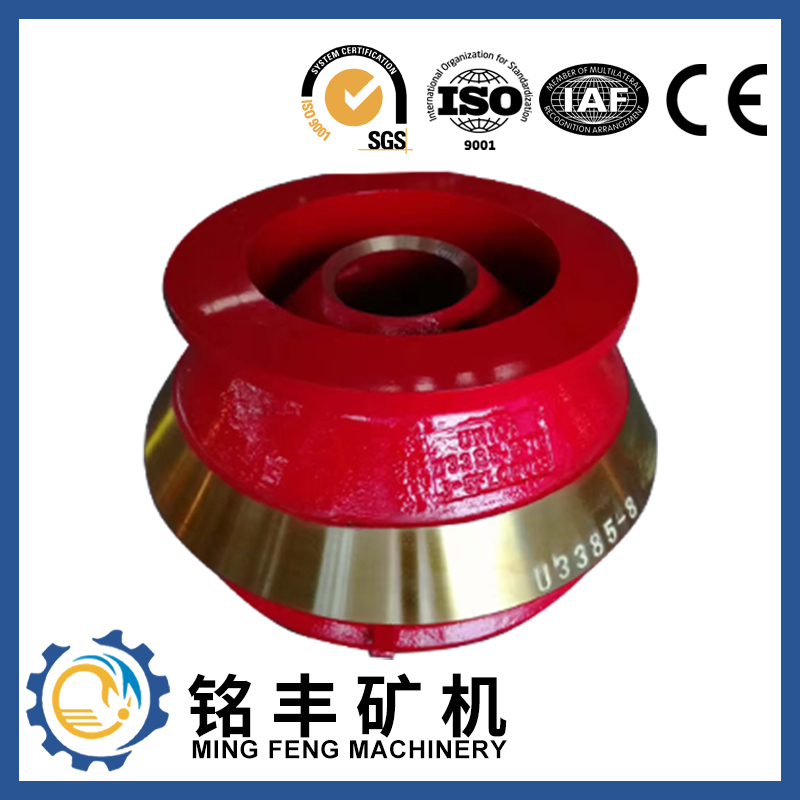

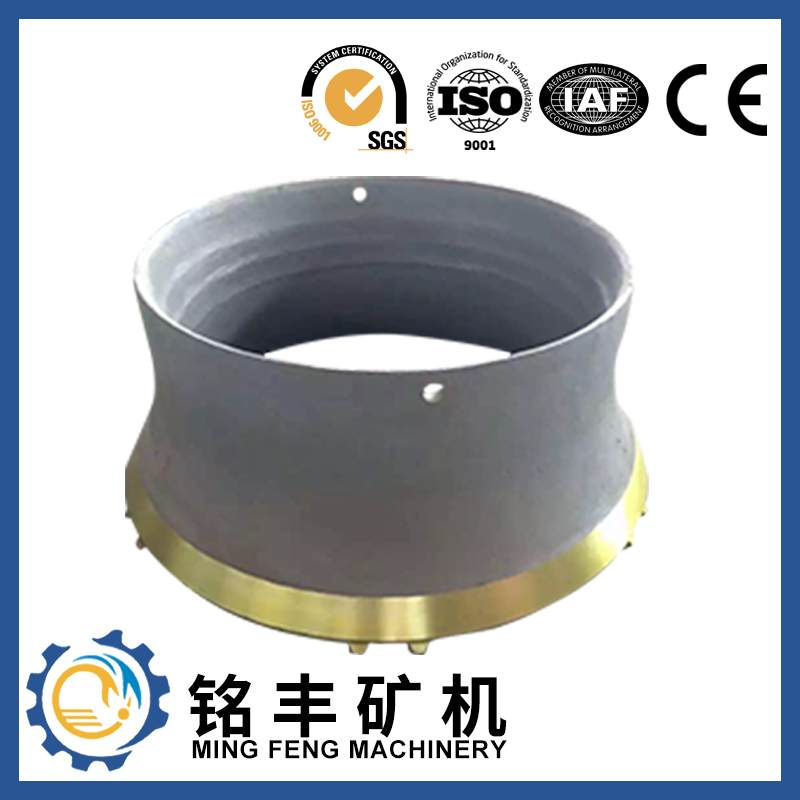

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for PriceList for Hammer Crusher Design - Mn13Cr2 hammer with carbide tip – MING FENG MACHINERY , The product will supply to all over the world, such as: Bahamas, Palestine, Greek, We have more than 10 years experience of production and export business. We always develop and design kinds of novel products to meet the market demand and help the guests continuously by updating our products. We are specialized manufacturer and exporter in China. Wherever you are, please join us, and together we will shape a bright future in your business field!

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed