Popular Design for Xa400 Jaw Crusher Specs - PEX-250×1200 jaw crusher – MING FENG MACHINERY

Popular Design for Xa400 Jaw Crusher Specs - PEX-250×1200 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PEX-250×1200 |

250×1200 |

210 |

20-60 |

330 |

37 |

25-60 |

7.7 |

Description:

Despite that the jaw crusher has been developed for many years, it is still widely used in fields of metallurgy, mining, chemical, construction, fireproof material, ceramics industry because of its simple structure, solidity, reliability, easy maintenance. It can be used to crush rocks with a fracture strength within 147-245MPa into coarse/medium/fine size. In order to meet the requirement of high crushing ratio and hardness of low carbon ferrochrome in fields of metallurgy, mining and construction nowadays, we have designed modern Jaw crusher.

It comprises the frame, the eccentric shaft, the grooved wheel, the flywheel, the mobile jaw, the side plate, the toggle plate, the captured spring, the fixed jaw plate and the mobile jaw plate, the safety device and the adjusting device, etc.

Working principle:

The motor drives the belt and the grooved wheel, and then makes the jaw move up and down through the eccentric shaft. When the jaw moves upwards, the angle between the liner plate and the jaw becomes larger, which will push the mobile jaw plate close to the fixed jaw plate, during which the material is crushed. When the mobile jaw moves downwards, the angle between the liner plate and the mobile jaw becomes smaller. The mobile jaw plate will leave the fixed jaw plate under the force the rod. The crushed material will drop from the discharge opening. With the motor rotating continuously, mass production can be realized.

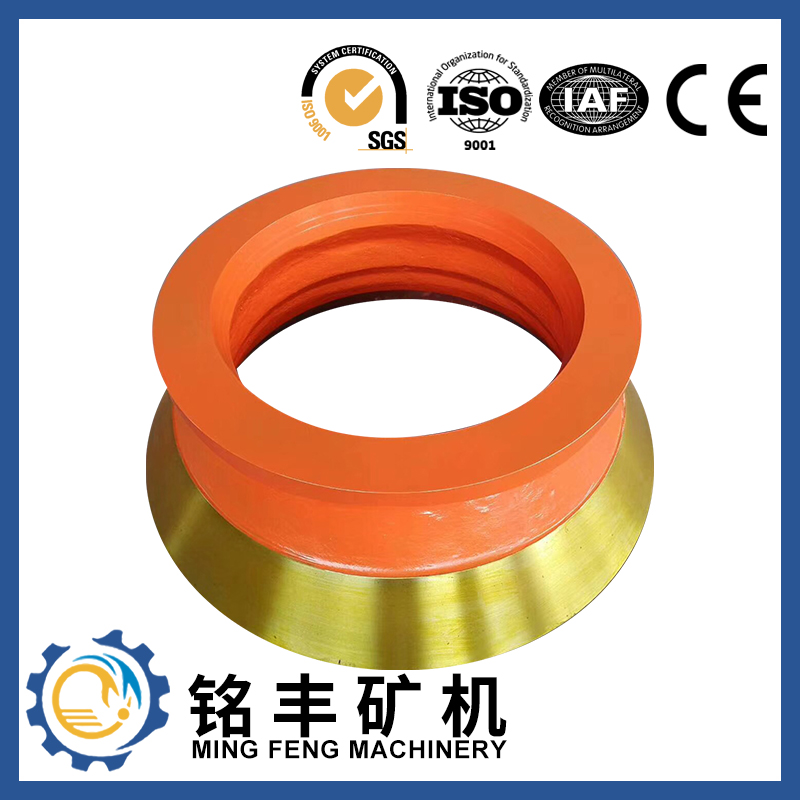

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Sticking towards the principle of Super High-quality, Satisfactory service ,We've been striving to become a superb business partner of you for Popular Design for Xa400 Jaw Crusher Specs - PEX-250×1200 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Argentina, Senegal, Russia, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good products quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed