Popular Design for Mp1250 Mantle - PE-500×750 jaw crusher – MING FENG MACHINERY

Popular Design for Mp1250 Mantle - PE-500×750 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PE-500×750 |

500×750 |

425 |

45-100 |

275 |

55 |

50-100 |

10.1 |

Description:

Jaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for crushing granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral &rocks.

This product uses a motor as power. A triangle belt and pulley drives eccentric shaft through the motor pulley to make the movable jaw do reciprocating motion according to a predetermined track.Then the materials in the crushing cavity, which consists of fixed jaw plate, movable jaw plate and the side plate, will be crushed. The final products will be discharged from the discharge port.

Working principle:

The motor drives the belt and the grooved wheel, and then makes the jaw move up and down through the eccentric shaft. When the jaw moves upwards, the angle between the liner plate and the jaw becomes larger, which will push the mobile jaw plate close to the fixed jaw plate, during which the material is crushed. When the mobile jaw moves downwards, the angle between the liner plate and the mobile jaw becomes smaller. The mobile jaw plate will leave the fixed jaw plate under the force the rod. The crushed material will drop from the discharge opening. With the motor rotating continuously, mass production can be realized.

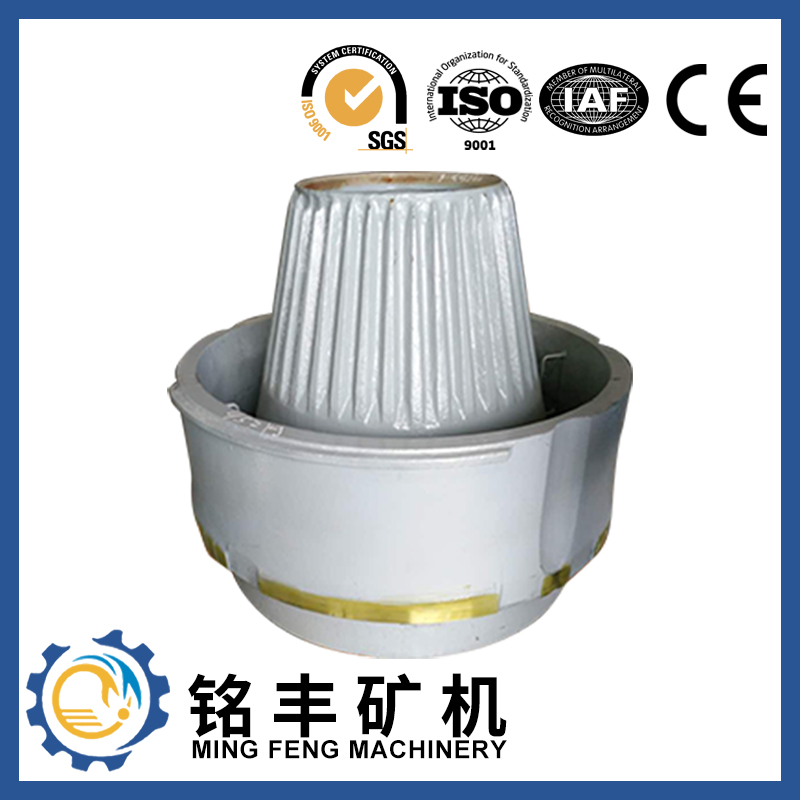

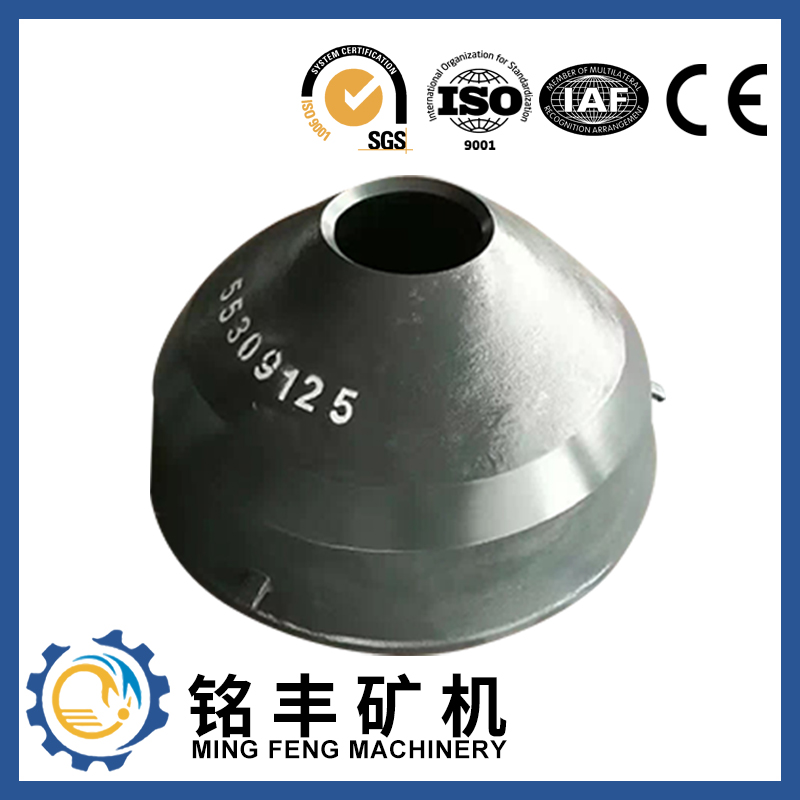

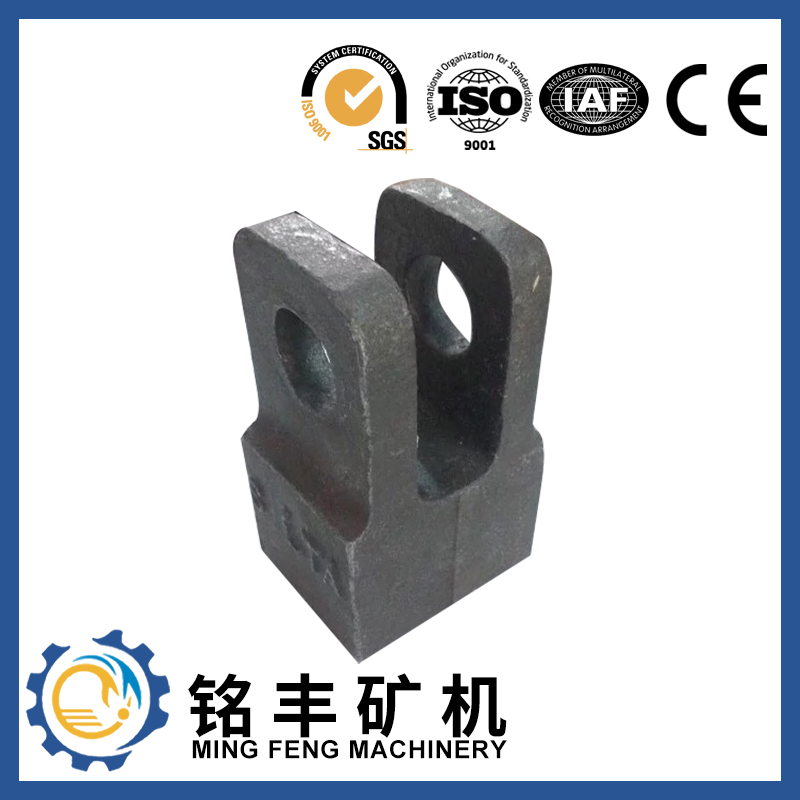

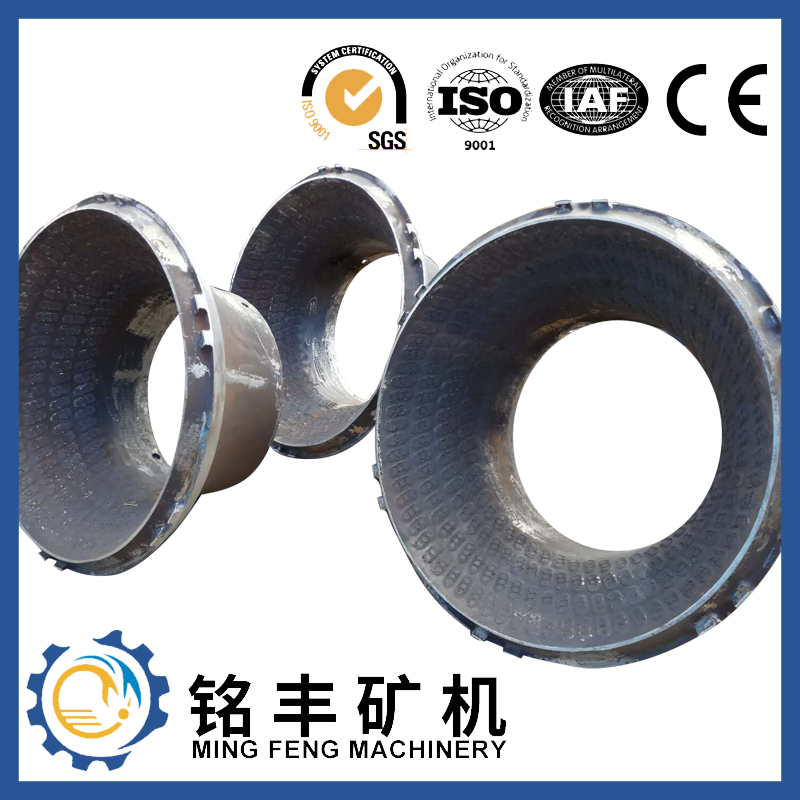

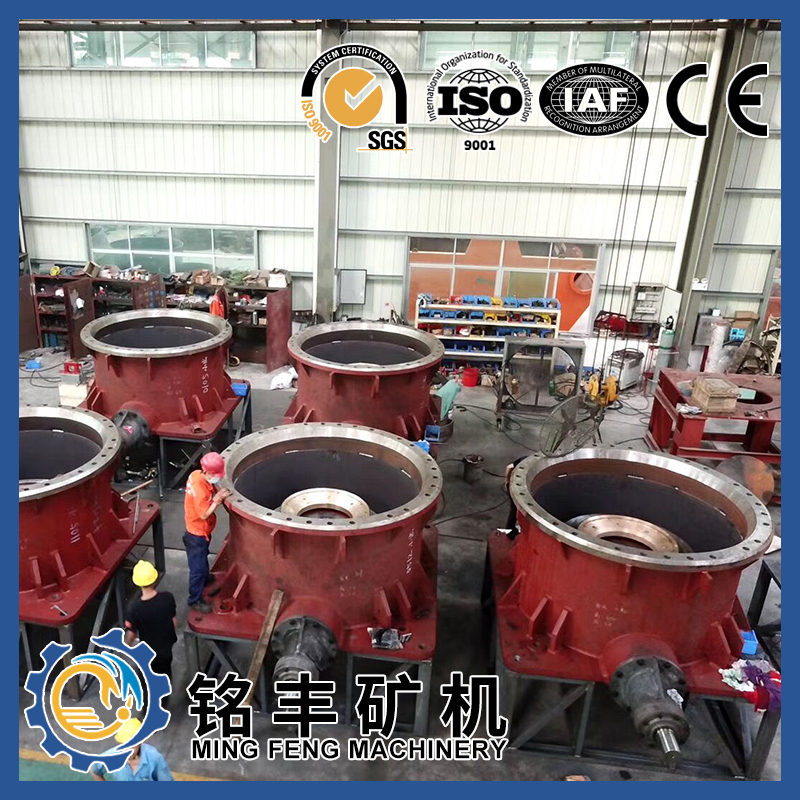

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

With this motto in mind, we've turn into one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Popular Design for Mp1250 Mantle - PE-500×750 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Paraguay, Albania, Lisbon, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

This supplier stick to the principle of Quality first, Honesty as base, it is absolutely to be trust.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed