Popular Design for Mining Equipment Newcastle - Roll crusher – MING FENG MACHINERY

Popular Design for Mining Equipment Newcastle - Roll crusher – MING FENG MACHINERY Detail:

Roll Crusher Technical Data:

|

Specification |

Max Feed Edge |

Discharge Size |

Production |

Power |

Weight |

|

2PG-400X250 |

≤25 |

1–8 |

5-10 |

11 |

1500 |

|

2PG-400X500 |

≤30 |

1–15 |

10-20 |

22 |

2600 |

|

2PG-610X400 |

≤40 |

1–20 |

13-35 |

30 |

4500 |

|

2PG-750X500 |

≤40 |

2–20 |

15-40 |

37 |

12250 |

|

2PG-900X500 |

≤40 |

3–40 |

20-50 |

44 |

14000 |

Description:

Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar characteristics in the mining, power generation and numerous other industries. Roll Crushers are one of the most widely used crushers in the mining industry and have numerous advantages, such as high capacity, low headroom, low horsepower, the ability to handle wet, sticky feeds and the generation of minimum fines while producing a cubical product.

The simplified design gives these units excellent reliability and requires very little maintenance. Roll Crushers are designed with built-in tramp relief that allows for the passing of uncrushable materials while continuing operation and returning to the initial product setting.

Working principle:

During operation, the two rollers, driven by the motor through the V-belt, rotate in the opposite direction. The material will be crushed by the rollers after passing the feed opening and then be discharged from the base. The wedge-shaped device or washer between the rollers is adjustable. At the top of the wedge-shaped device, there is a bolt for adjusting. When the wedge-shaped device is pulled up by the bolt, the rollers will leave the fixed wheel. In the case, particles obtained become larger. While the wedge-shaped device moves downwards, the distance between the rollers becomes short under the influence of pressed springs. In the case, particles obtained become smaller. By increasing/decreasing the number or thickness of the washer, larger/smaller particles can also be obtained.

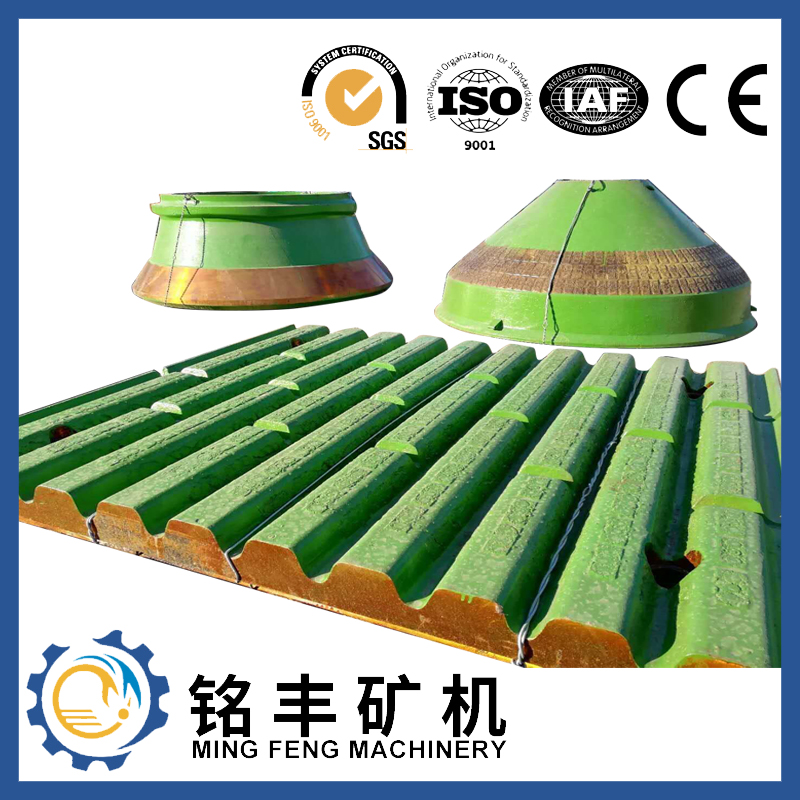

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

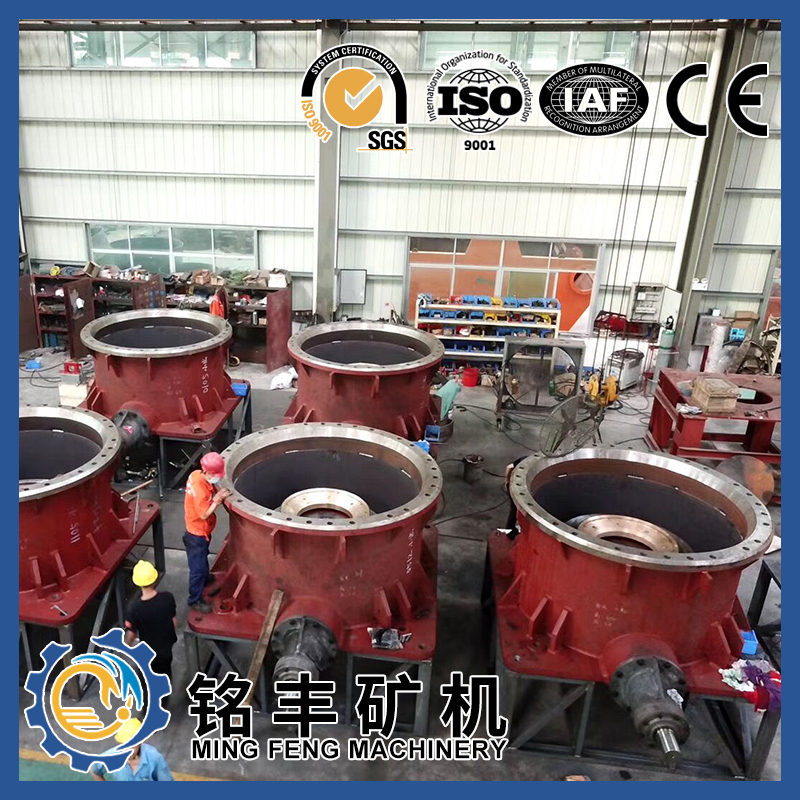

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for Popular Design for Mining Equipment Newcastle - Roll crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Lebanon, The Swiss, Qatar, Our company has already had a lot of top factories and professional technology teams in China, offering the best products, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed