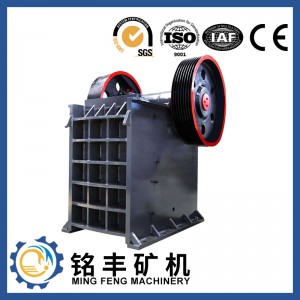

PE-750×1060 jaw crusher

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PE-750×1060 |

750×1060 |

630 |

52-180 |

250 |

110 |

80-140 |

28 |

Description:

jaw crusher is used in primary crushing for stones and bulk materials .It processes various kinds of ore with compression strength not more than 320mp. It is widely applied in mining, quarry, metallurgy, building, highway, railway, construction wastes processing, water conservancy and cement production, etc. .The jaw crusher is divided into the coarse jaw crusher and the fine jaw crusher

It comprises the frame, the eccentric shaft, the grooved wheel, the flywheel, the mobile jaw, the side plate, the toggle plate, the captured spring, the fixed jaw plate and the mobile jaw plate, the safety device and the adjusting device, etc.

Advantages:

1. The movable jaw assembly uses high quality casting steel;

2. Simple structure, easy operation, convenient maintenance.

3.Large adjustable range of discharge opening can meet the different requirements of different specifications.

4.The heavy eccentric shaft adopts forging, heat treatment, annealing, crack detection etc. processing,then it can guarantee the stability of lead plane.

5. Deep crushing cavity and without dead zone, improve the ability of feed and output.

6. The inner bearing uses aligning roller, double row double roller bearing which can guarantee it with higher carrying capacity.

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed