Online Exporter Ch890 Concave - PE-1000×1200 jaw crusher – MING FENG MACHINERY

Online Exporter Ch890 Concave - PE-1000×1200 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PE-1000×1200 |

1000×1200 |

850 |

160-300 |

200 |

110 |

195-265 |

51 |

Description:

Jaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for crushing granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral &rocks.

This product uses a motor as power. A triangle belt and pulley drives eccentric shaft through the motor pulley to make the movable jaw do reciprocating motion according to a predetermined track.

Then the materials in the crushing cavity, which consists of fixed jaw plate, movable jaw plate and the side plate, will be crushed. The final products will be discharged from the discharge port.

Advantages:

1.High stability and high reliability

2.Advanced Technology And Long Service Life

3.Simple Structure, Convenient Repair

4.Good capacity and fine size

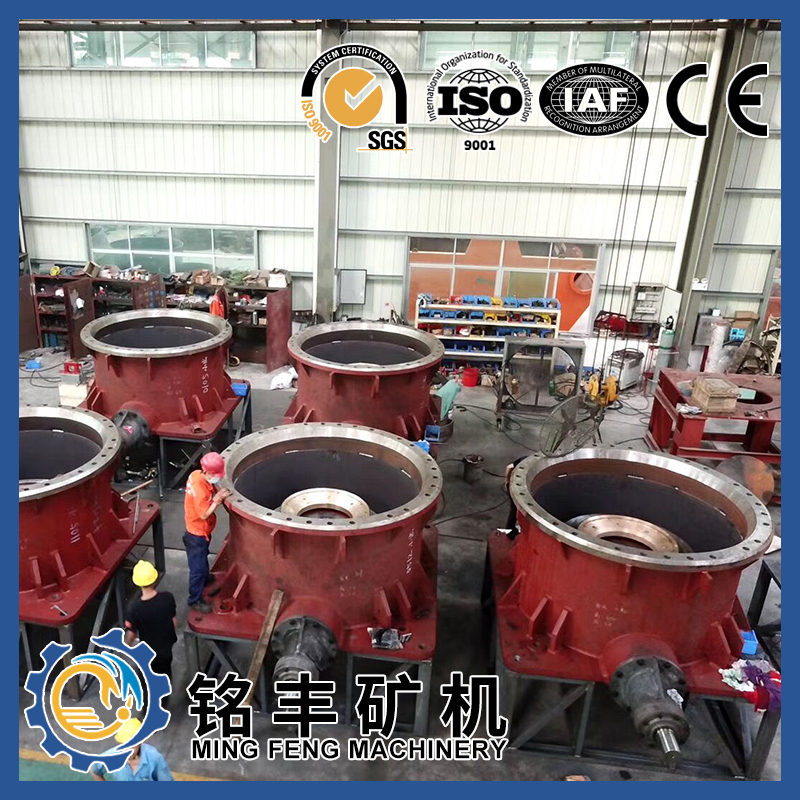

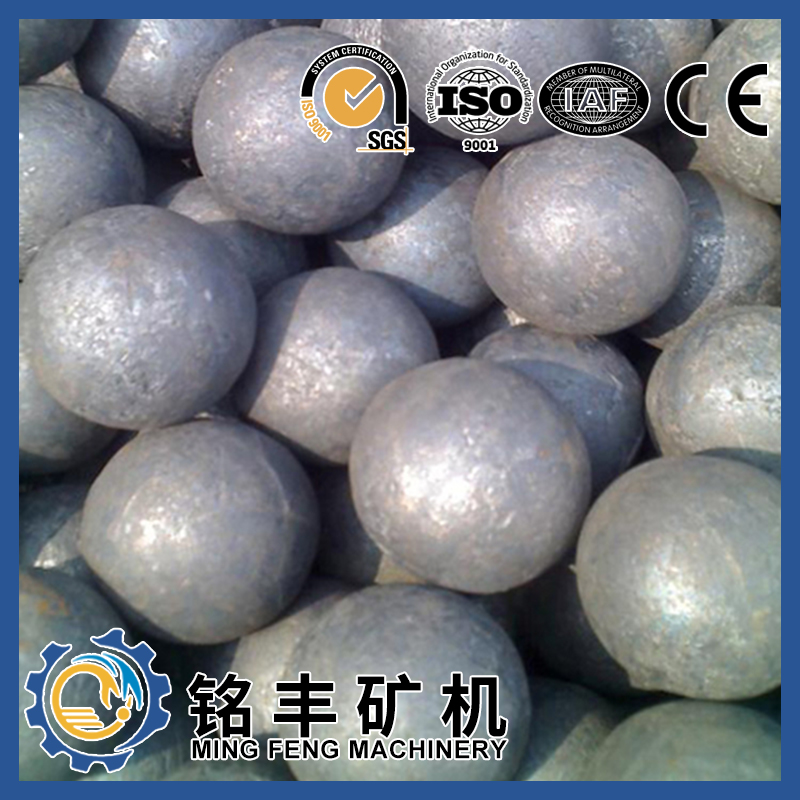

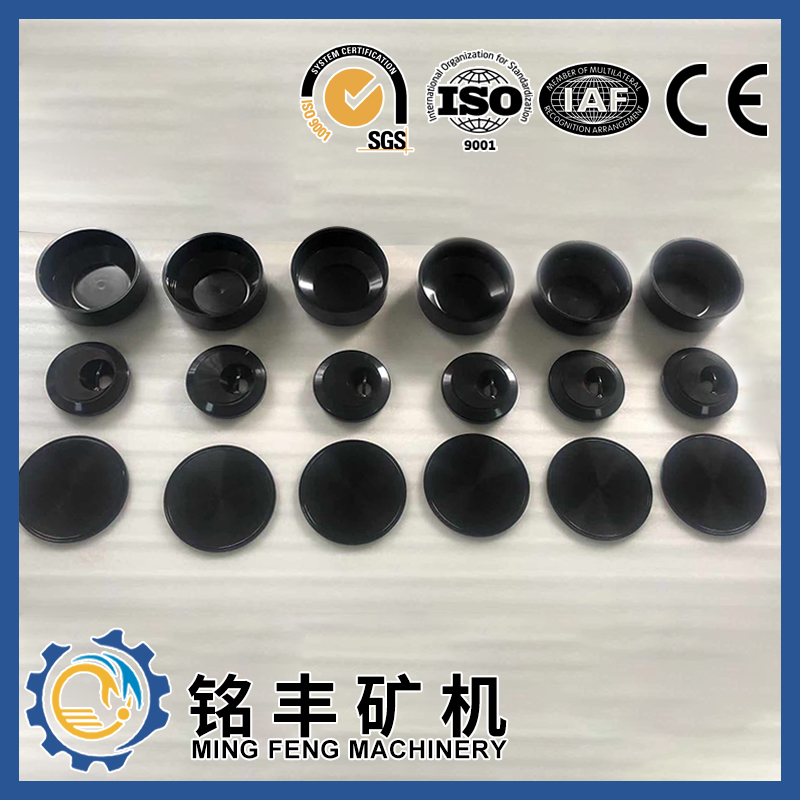

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto High High-quality, Competitive Price tag, Fast Service for Online Exporter Ch890 Concave - PE-1000×1200 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Iran, Bangalore, Grenada, In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed