OEM/ODM Supplier Mn18% Swing Jaw - High Mn (Manganese) ceramic composite mantle/cone/jaw plate – MING FENG MACHINERY

OEM/ODM Supplier Mn18% Swing Jaw - High Mn (Manganese) ceramic composite mantle/cone/jaw plate – MING FENG MACHINERY Detail:

Description:

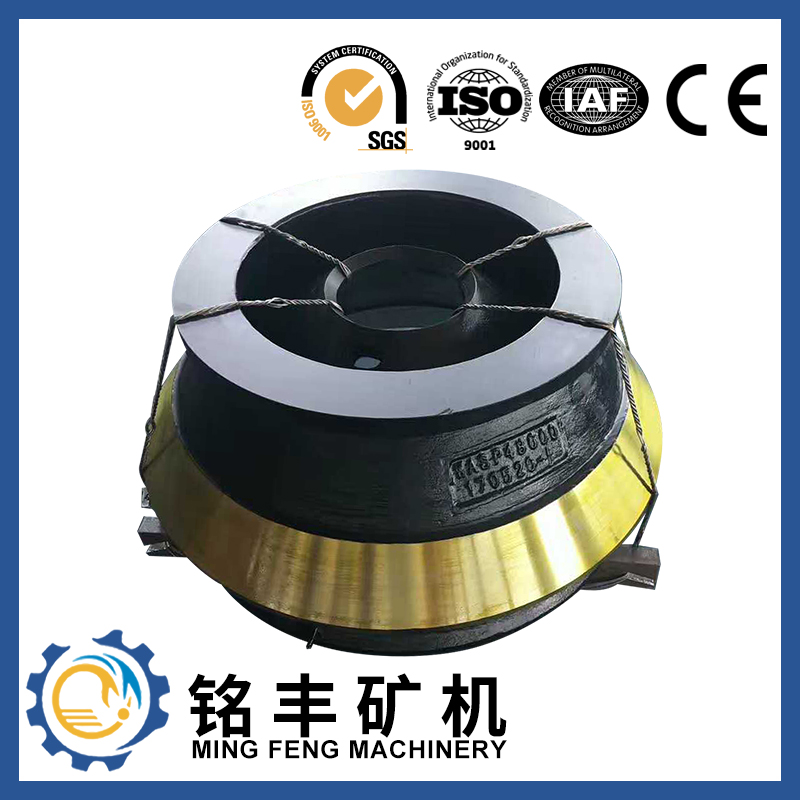

Work part of the jaw crusher is two pieces of jaw plate, one is the fixed jaw plate (fixedjaw), which is vertical (or the upper slightly extraversion) fixed in front of the body wall, the other is movable jaw plate (movable jaw),which is tilt, form big end dowm crushing cavity (work cavity). movable jaw plate press the fixed jaw plate with periodic reciprocating motion, sometimes separately, sometimes near. Separately, material into the crushing cavity, finished products dischargefrom the lower ; Approached, the materials are squeezed between two pieces of jaw plate, bending and fracturing effect to broken.

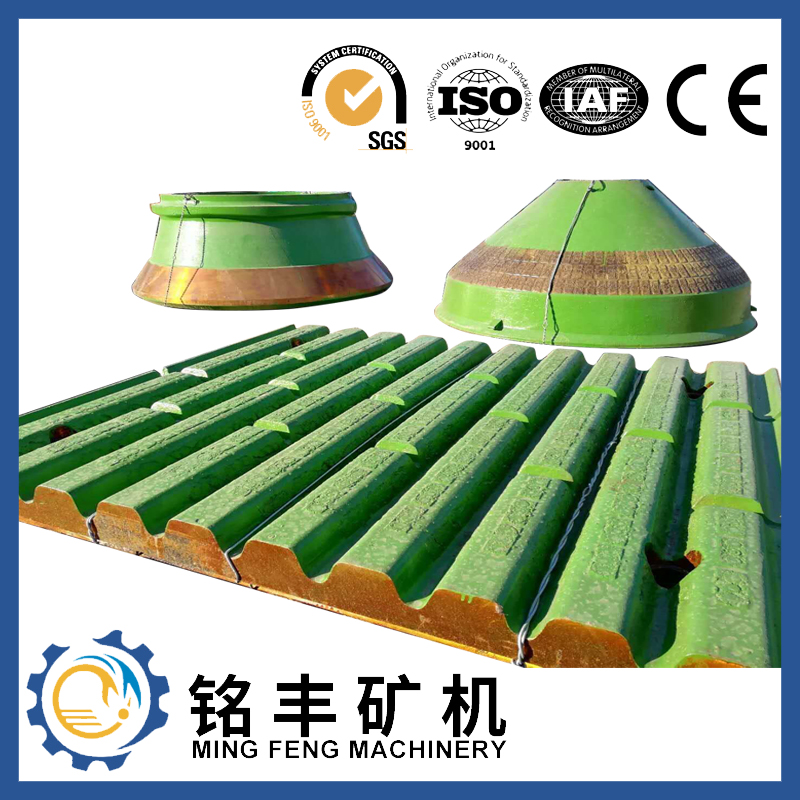

MF choose high manganese steel as metal matrix, high manganese steel embed the high wear resistant with stiffener into metal matrix. The original work hardening of high manganese steel impact resistance performance is remaining, meanwhile the wear resistance strength of high manganese steel ceramic composite

Advantages:

1. Increased Wear Life – MGS Casting’s unique TiC insert cone liners and bowl liners design features a strengthened high-wear zone for maximum usable wear life and reduced breakage.

2. Strengthens as It Works – Concaves and mantles body are cast in durable manganese steel (Mn18Cr2) that gets harder the longer you work it.

3. Consistent Wear – More consistent wear profile for uniform product output and increased efficiency.

4. Titanium Carbides – TiC inserts currently available are 20mm, 40mm, 60mm, and 80mm depths.

5. Fewer Change-Outs – Greater durability and longer wear life means fewer change outs, more up-time, and lower maintenance costs

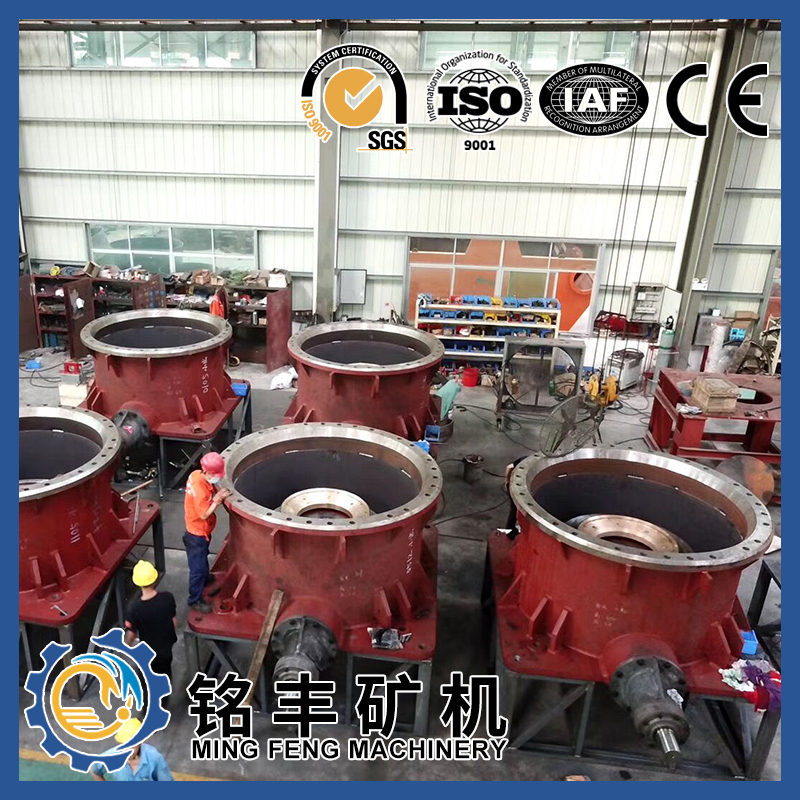

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1. 30 years of manufacturing experience, 6 years of foreign trade experience

2. Strict quality control, Own laboratory

3. ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency profits team values customers' requirements and organization communication for OEM/ODM Supplier Mn18% Swing Jaw - High Mn (Manganese) ceramic composite mantle/cone/jaw plate – MING FENG MACHINERY , The product will supply to all over the world, such as: Brunei, Ethiopia, Sierra Leone, We always hold on the company's principle honest, professional, effective and innovation, and missions of: let all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We are determined to become the integrator of our product market and one-stop service provider of our product market.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed