OEM/ODM Factory Jaw Crusher Auction - PF-1010 impact crusher – MING FENG MACHINERY

OEM/ODM Factory Jaw Crusher Auction - PF-1010 impact crusher – MING FENG MACHINERY Detail:

Impact Crusher Technical Data:

|

Model |

Spec of Rotor |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Motor Power |

Weight |

Overall Dimensions |

|

PF-1010 |

Φ1000×1050 |

400×1080 |

350 |

50-80 |

55-75 |

12.2 |

2400×2250×2660 |

Descriptions:

Impact crushers (also known as impactors or horizontal shaft impactors) can be used in primary, secondary, or tertiary applications. They use inertia of the blowbars fitted to the rotor to fracture the material, resulting in a high reduction ratio. Impactors are often used as a cost effective alternative to jaw and cone combination plants as they have a good level of reduction and product shaping for many applications. It has become an ideal equipment to make aggregate for highway, high-speed railway, airport and hydroelectric project.

This kind of crusher can deal with ores and rocks with sizes below 350 mm and fracture strength within 350MPa. There are three types which are used in fields of mining, cement making and concrete making respectively. The rotor and the chambers can be customized.

Advantages:

1.High throughput rates

2. Powerful rotors

3.Flexible configuration for any shredding application

4. Largely standardized and interchangeable wear parts

5. Low maintenance requirements

6. Quick and simple blow bar replacement

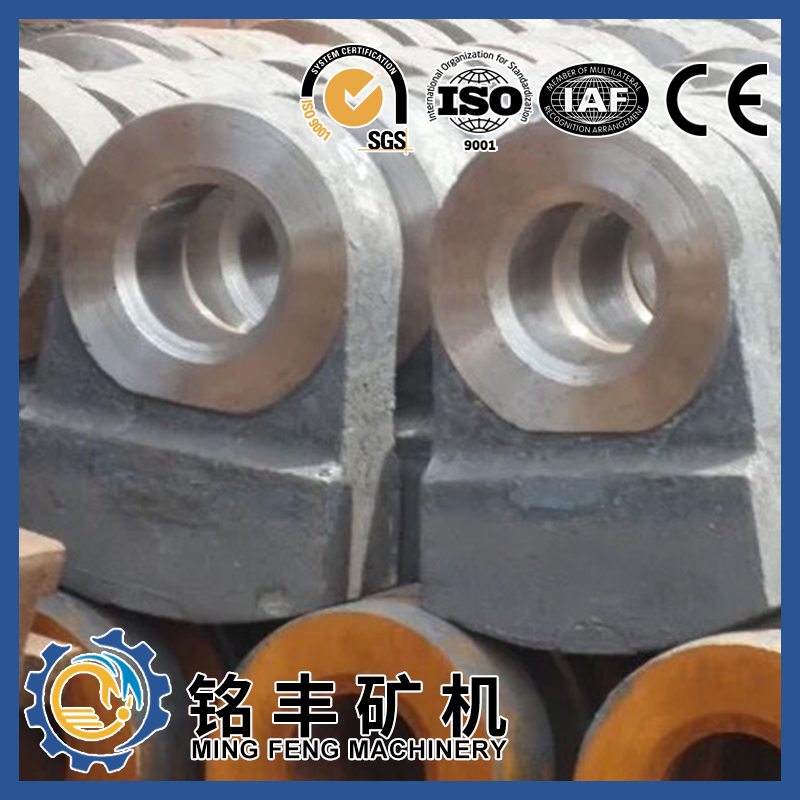

Crusher Parts:

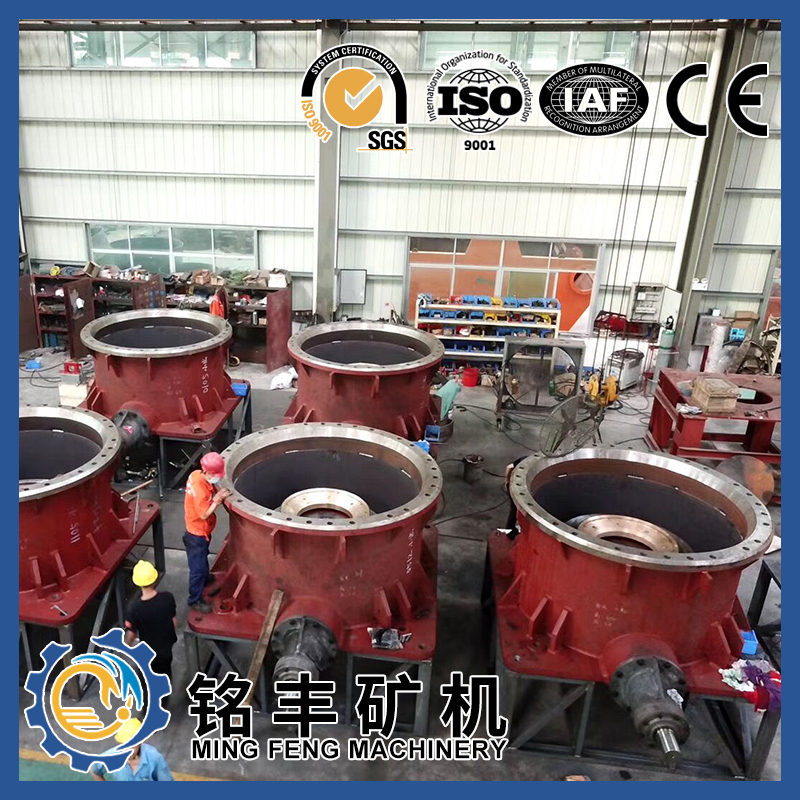

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for OEM/ODM Factory Jaw Crusher Auction - PF-1010 impact crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Luxembourg, Iceland, Islamabad, For anyone who is keen on any of our items right after you view our product list, you should definitely feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our merchandise by your self. We're always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed