OEM Supply Rod Mill Bond Index - Forged steel ball/ forged steel media ball – MING FENG MACHINERY

OEM Supply Rod Mill Bond Index - Forged steel ball/ forged steel media ball – MING FENG MACHINERY Detail:

Overview:

| Type | Forged steel ball, Forged steel media ball | ||

| Specification | 45#, 50Mn, 60Mn, 65Mn, B2, B3, BL, BG | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Ball Mill Liner | Certification | ISO 9001:2008 |

| Main Materials | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Processing Type | Casting | Impact Toughness | >12ak.J/Cm^2 |

| Casting Inspection | spectrometer, hardness tester, microscope, drop tester, impact tester, laser cutting machine, etc. | ||

| Transport Package | Steel Drums & Flexible Container Bags | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

We can also arrange special processing for different requirements of the steel raw material. We use an electric furnace to heat the raw material, in order to make sure all the materials can reach the correct temperature and reduce unnecessary loss during heating .To obtain high hardness, strength, toughness and superior wear resistance, the forged steel balls undergo heat treatment, water quenching, and tempering. During the heat treatment, we use advanced Isothermal temperature control technology, to insure the uniformity of the hardness of the grinding balls.

Casting Material Chemical Composition:

| Material | C | Mn | Si | Cr | P/S |

| 45# | 0.42-0.48 | 0.50-0.80 | 0.17-0.37 | ≤ 0.25 | ≤ 0.035 |

| 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤ 0.25 | ≤ 0.035 |

| 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤ 0.25 | ≤ 0.035 |

| 65Mn | 0.62-0.70 | 0.90-1.20 | 0.17-0.37 | ≤ 0.25 | ≤ 0.030 |

| B2 | 0.75-0.85 | 0.70-0.90 | 0.17-0.37 | 0.40-0.60 | ≤ 0.030 |

| B3 | 0.55-0.65 | 0.75-0.90 | 0.20-0.37 | 0.85-1.20 | ≤ 0.030 |

| B4 | 0.58-0.66 | 0.65-0.80 | 1.60-1.90 | 0.70-0.90 | ≤ 0.030 |

| B6 | 0.97-1.03 | 1.00-1.10 | 0.20-0.30 | 0.50-0.60 | ≤ 0.025 |

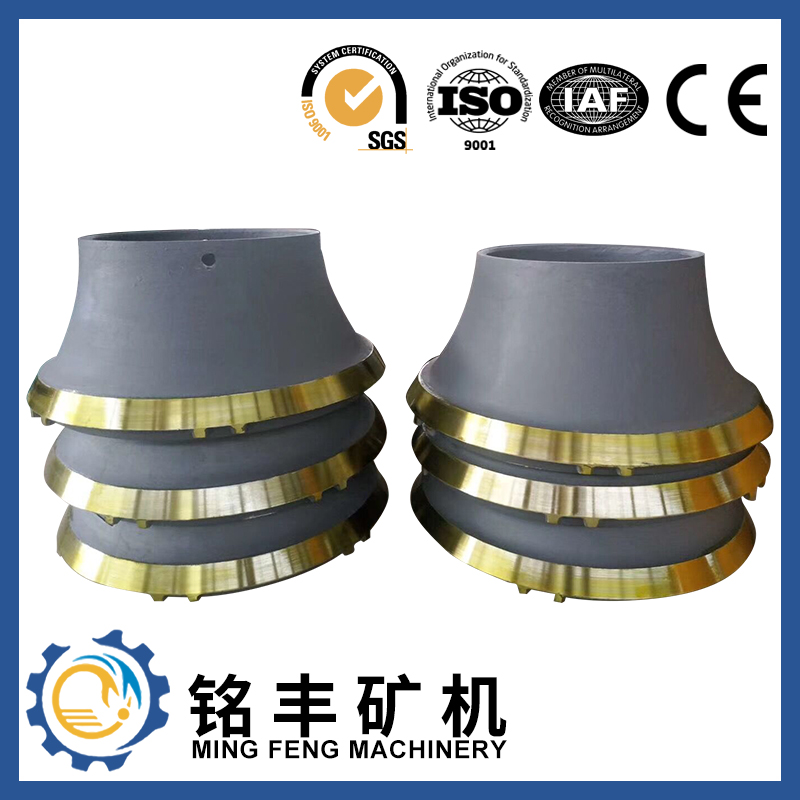

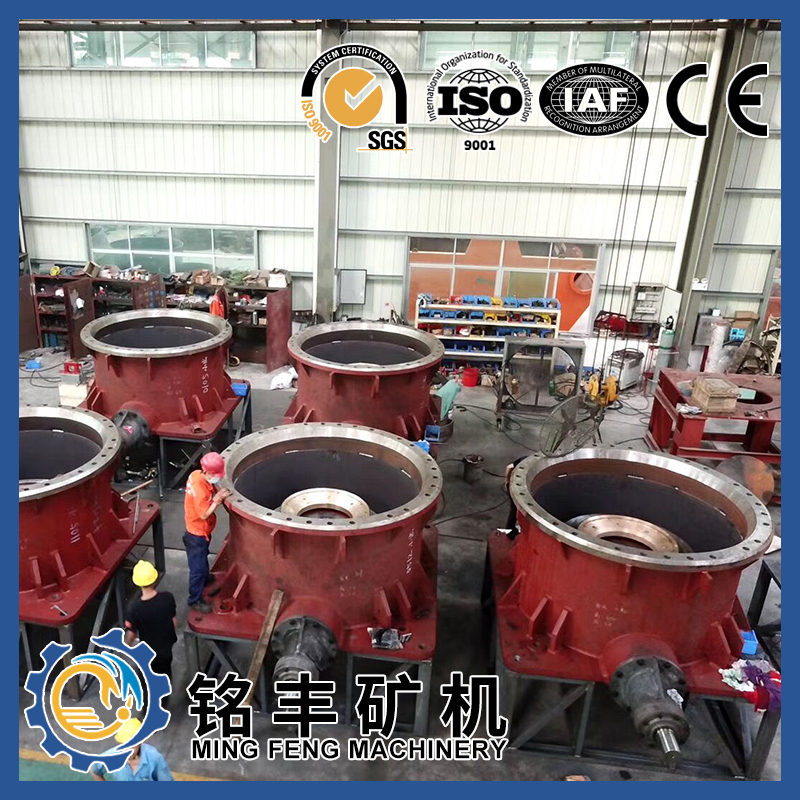

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for OEM Supply Rod Mill Bond Index - Forged steel ball/ forged steel media ball – MING FENG MACHINERY , The product will supply to all over the world, such as: Costa rica, Congo, Kyrgyzstan, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed