OEM Supply Mn13cr2 Swing Jaw - Carbide insert hammer in casting – MING FENG MACHINERY

OEM Supply Mn13cr2 Swing Jaw - Carbide insert hammer in casting – MING FENG MACHINERY Detail:

Application:

Cement Mill Hammer

Challenge:

Improve wear life and avoid costly shutdowns of the kiln due to part replacement.

Solution:

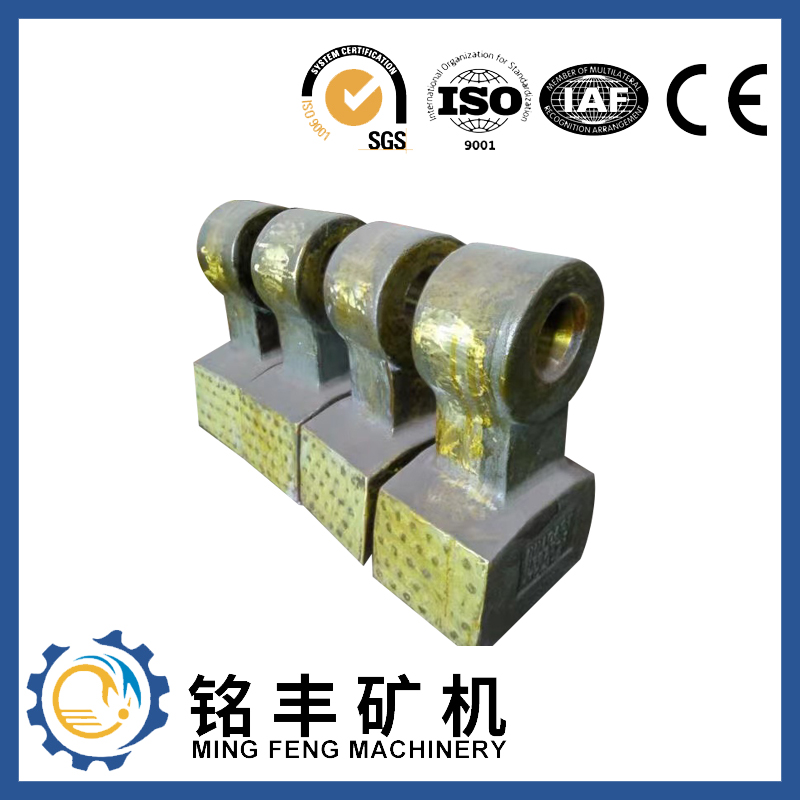

Replace the manganese hammers with 40mm TiC hammers.

Results:

MGS Casting’s 40mm TiC hammers outperformed the previous parts by more than

2.5 times.

Description:

During the casting process, TiC columns are held vertically with a proprietary system in the sand mould. The columns are positioned for maximum surface coverage in the hammer’s high-wear zone. Manganese or wear alloy is poured into the mould and then the hammer undergoes a special hardening procedure. The TiC columns provide structural strength to the hammer while the manganese or wear alloy gives the hammer the flexibility to handle the impact. Both alloys work together to lengthen the overall wear life of the wear part.

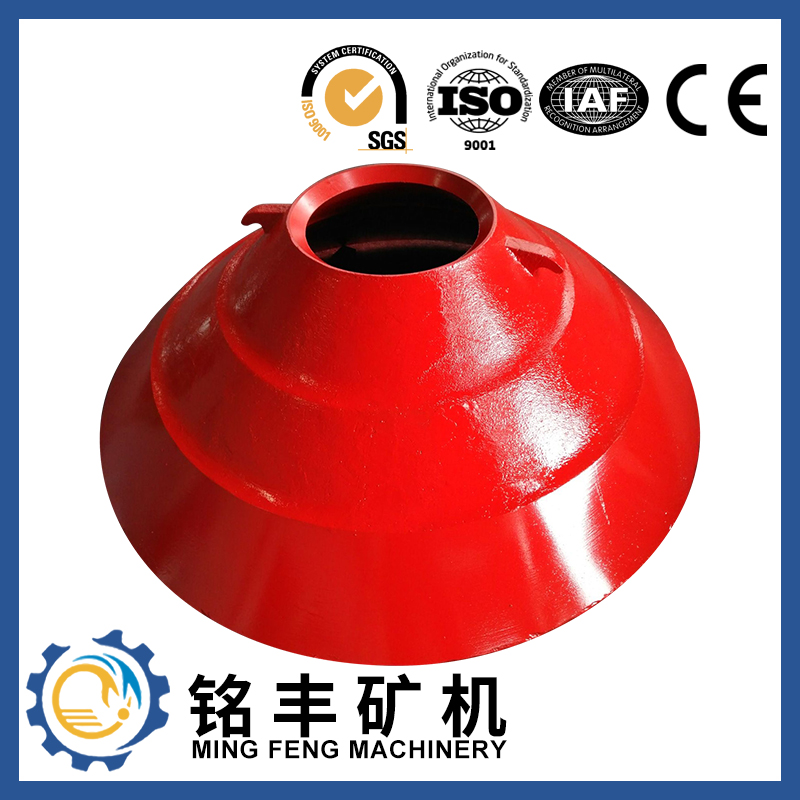

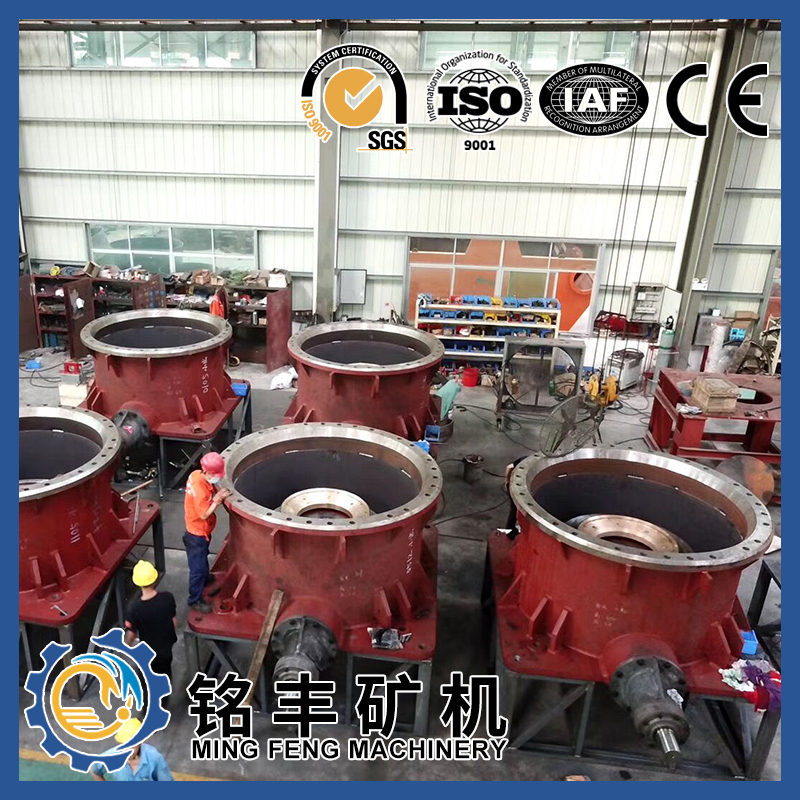

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1. 30 years of manufacturing experience, 6 years of foreign trade experience

2. Strict quality control, Own laboratory

3. ISO9001:2008, BUREAU VERITAS

4. First class workmanship.Reliable quality with CE approved, reaching to European standard

5. Stationary type or mobile type for choosing

6. Complete stone production line, the Crusher near to turn-key project;

Product detail pictures:

Related Product Guide:

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for OEM Supply Mn13cr2 Swing Jaw - Carbide insert hammer in casting – MING FENG MACHINERY , The product will supply to all over the world, such as: Sri Lanka, Montreal, Saudi Arabia, With the enterprising spirit of high efficiency, convenience, practicality and innovation, and in line with such serving guidance of good quality but better price, and global credit, we are striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed