The reason:

1. Due to the wear of the lower part, the feeding port of the rolling mortar wall becomes smaller, which restricts the ore from entering the crushing cavity;

2. The running speed of the crusher is low;

3. The feeding humidity is too high, which reduces the moving speed of the material in the crushing cavity;

4. The oversized plate material is stretched in front of the feeding port on the top of the liner;

5. The feed contains large pieces of wood, tree roots, chopping wood and other debris, which makes the material move slowly;

6. The upper limit size of the feed is too large;

7. There is a lot of clay in the feed;

8. Improper feed distribution, feed segregation causes the fine material to be fed into one side of the crushing cavity;

9. The spindle is broken or cracked.

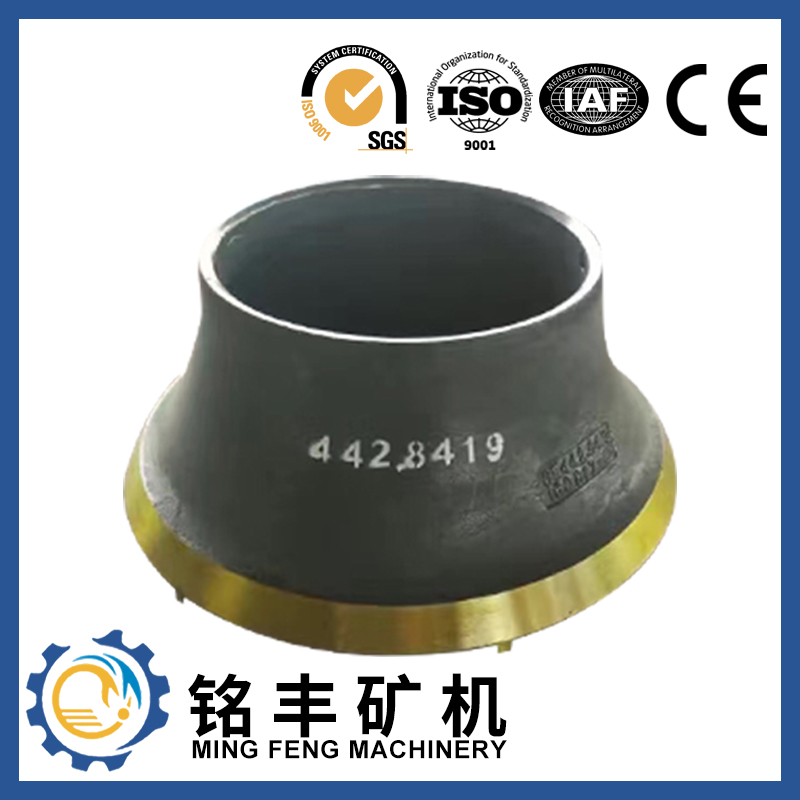

CS Series Cone Crusher Wear Parts

CS Series Cone Crusher Wear Parts

Post time: Jun-23-2021