Manufacturer of Jaw Crusher Bucket For Sale - PE-870×1060 jaw crusher – MING FENG MACHINERY

Manufacturer of Jaw Crusher Bucket For Sale - PE-870×1060 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PE-870×1060 |

870×1060 |

670 |

181-210 |

250 |

110 |

200-260 |

30.5 |

Description:

The Jaw crusher uses the principle of mutual extrusion of the jaws to process the material. It used in the first step for a variety of ore rock broken. All kinds of ores which compressive strength is not higher than 320Mpa can be one-time processing to moderate granularity. Often forms a complete set of sand production line with the cone crusher, impact crusher, sand making machine, etc. It widely used in mining, metallurgy, chemical industry, building materials, electricity, water conservancy, transportation and other fields.

Suitable Material:

Granite, marble,basalt, limestone, quartz, pebble, iron ore, copper ore, etc.

Advantages:

1. Low noise,little dust.

2. Crushin gravity depth and no blind spot, increasing the feeding ability and capacity.

3. High crushing ratio, uniform product size.

4. Simple structure, convenient in use and maintenance. Stable performance, low operationcost.

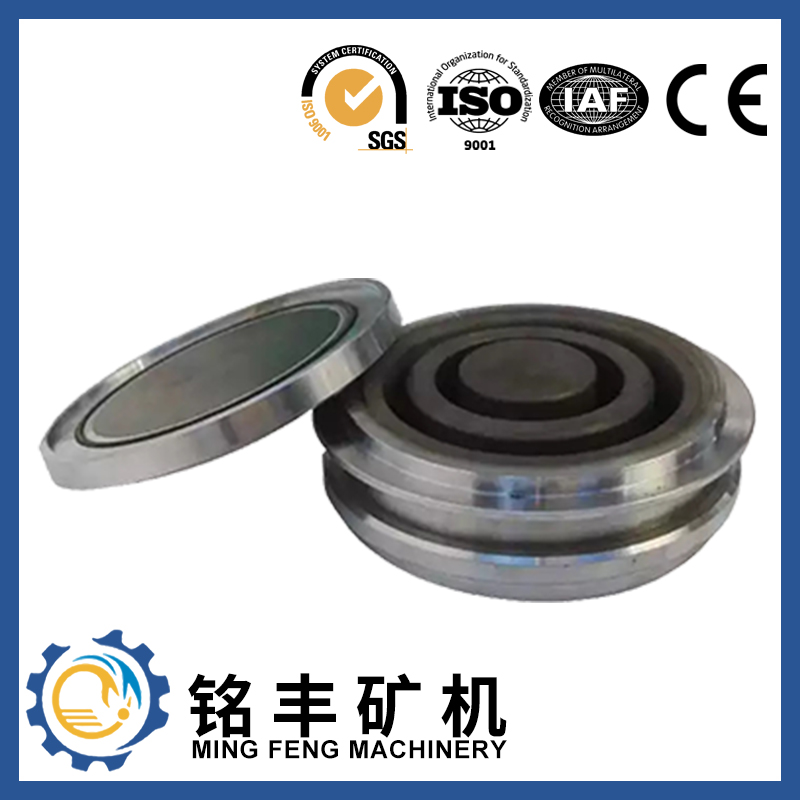

5. Lubrication system safe and reliable, easy to parts replacement, small maintenance workload.

6. Energysaving: stand-alone energy saving 15% ~ 30%, the system energy saving more thandouble.

7. Gasket type discharging mouth adjusting device, reliable, convenient and the adjustingrange is big, increase the flexibility of the equipment,can meet the requirements of different users.

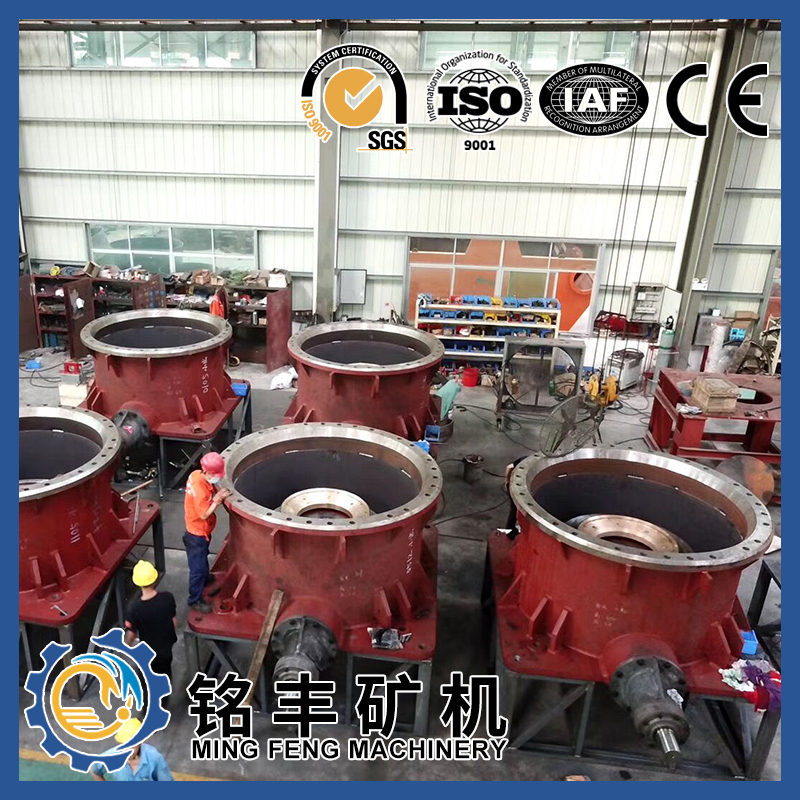

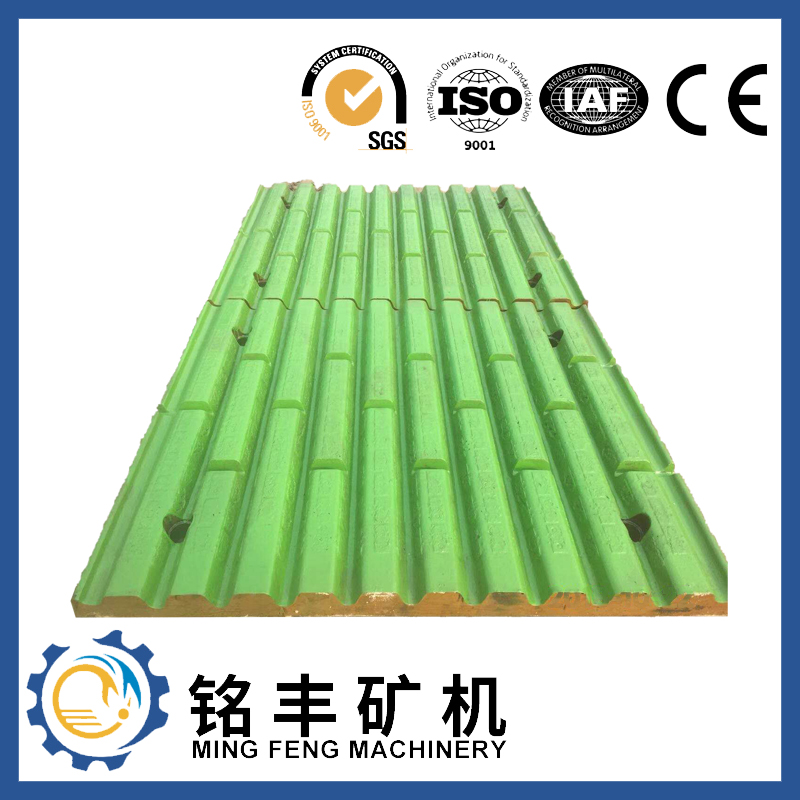

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for Manufacturer of Jaw Crusher Bucket For Sale - PE-870×1060 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: panama, Singapore, Bulgaria, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed