Manganese quarry crusher liners

Overview:

| Type | movable, swing jaw, fixed jaw plate | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | jaw Crusher | Certification | ISO 9001:2008 |

| Hardness | HB220~240 | Production Capability | More than 50000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Casting Manufacturing Process:

1、Pouring the molten iron water into the pattems

2、The know-how H.t(the temperature and time are controlled)heat treatment

3、To Maching the casting High Chrome or high manganese according to the drawing.

4、Water quenching Treatment

5、Grinding the surface

6、Quality inspection (Dimensional inspection, hardness inspection, mettallographic structure, etc)

7、Finish products with no painting

8、Finish products with painting in container

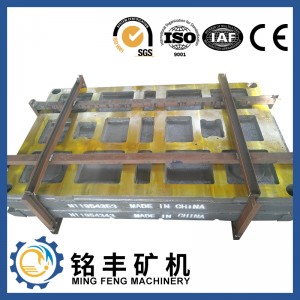

MF Jaw Crusher Parts Include:

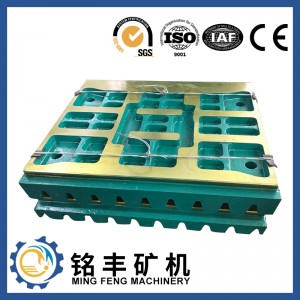

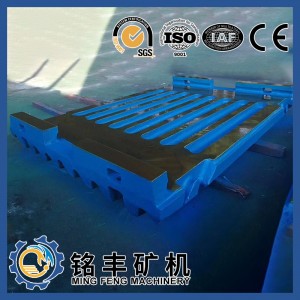

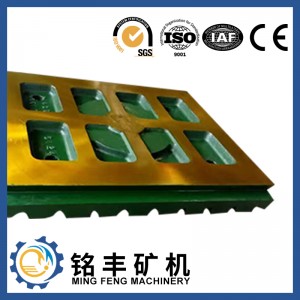

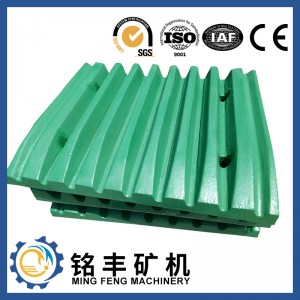

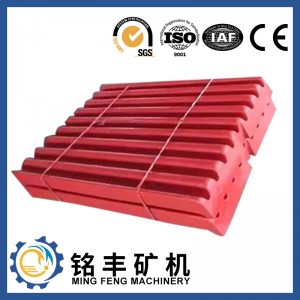

Jaw Plate

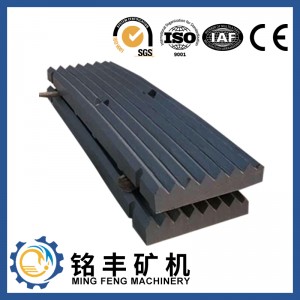

Every jaw crusher has two jaw plates, fixed jaw plate, and movable jaw plate. All jaw plates are manufactured by high manganese steel. In order to extend their service life, the jaw plate shape is designed to be upper and lower symmetrical, so one of the end areas wear out, turn over the jaw plate to continue to use. The fixed jaw plate and movable jaw plate are the main areas when the stone is crushed, and the movable jaw plate is mounted on the moving jaws to protect the moving jaws.

Jaw Crusher Tension Rod

Without the tension rod & spring the bottom of the pitman would just flop around as it isn’t connected to the toggle plate, rather just resting against it in the toggle seat. The tension rod system tensions the pitman to the toggle plate as shown in the illustrations.

Jaw Crusher Main Shaft

The pitman is put in motion by the oscillation of an eccentric lobe on a shaft that goes through the pitman’s entire length. This movement might total only 1 1/2″ but produces substantial force to crush material. This force is also put on the shaft itself so they are constructed with large dimensions and of hardened steel.

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1. We offer a variety tooth profiles and surface shapes;

2. We extend the service life of the jaw dies;

3. The fitting surfaces on all of our jaws are machine finished to ensure the best possible fit;

4. We provide more competitive prices.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed