Low price for High Mn Swing Jaw - Mn18Cr2 ceramic composite Mantle /cone – MING FENG MACHINERY

Low price for High Mn Swing Jaw - Mn18Cr2 ceramic composite Mantle /cone – MING FENG MACHINERY Detail:

Description:

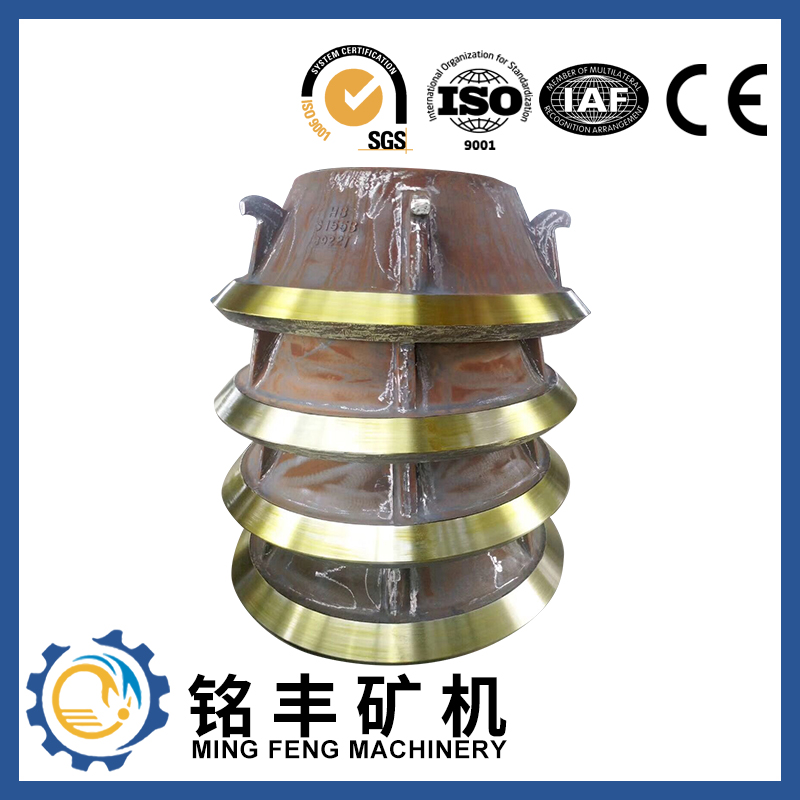

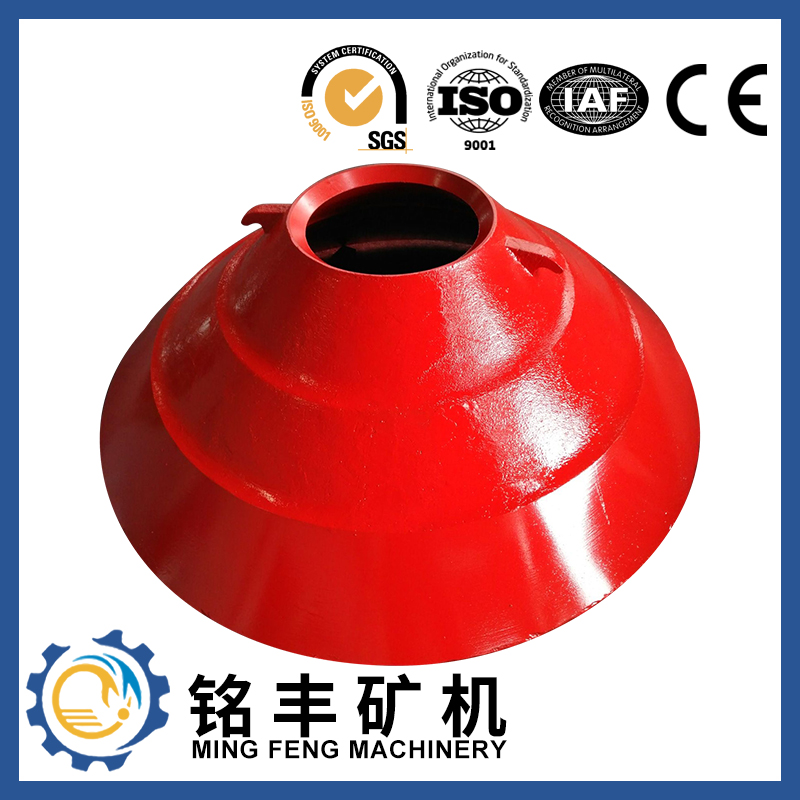

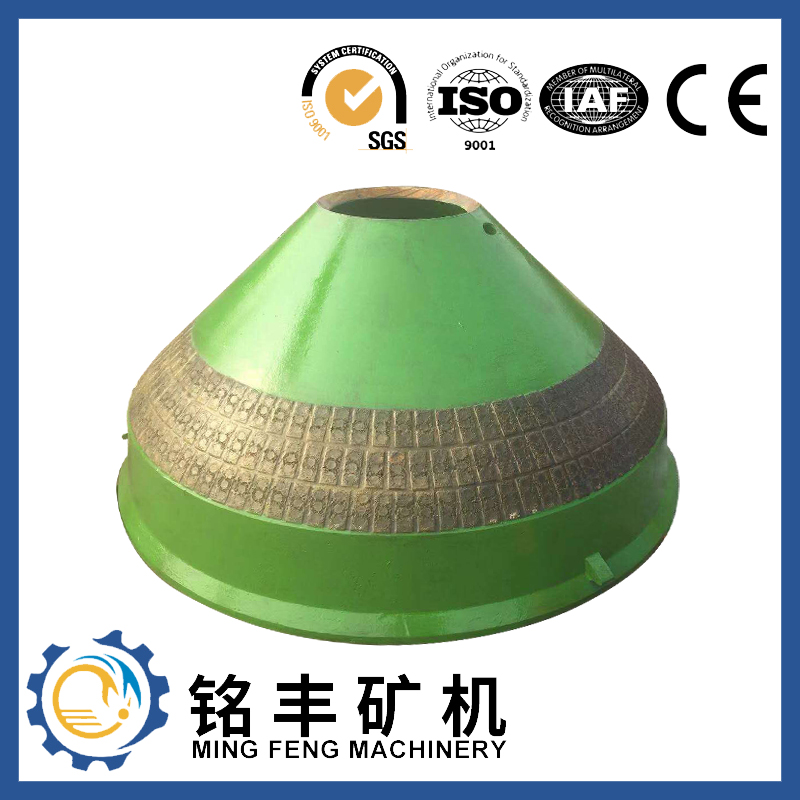

At present, cone and mantel are mostly made of high Mn steel. They will crack easily under strong impact loads, and the crushing process of extrusion, grinding effect of material. At the same time, the material has a relatively friction between them and the cutting action, so the parts wear out seriously. MF adopts composites of high-manganese steel substrate and ceramic , namely, the base material of the cone and mantle is high Mn steel, while the cast ceramic matrix embedded with high wear resistance shaped ribs, increase the wear resistance ability while maintaining the original impact resistance of high manganese steel. The life span of ceramic composite cone and mantle is more than 2 times of the ones made of high Mn steel.

Applications:

Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

Product Benefits:

Compared with the general market products, our products smooth surface, accurate dimensions , high wear resistance and longer life. Direct sales by the company foundry, cost-effective products.

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for Low price for High Mn Swing Jaw - Mn18Cr2 ceramic composite Mantle /cone – MING FENG MACHINERY , The product will supply to all over the world, such as: Saudi Arabia, Palestine, USA, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

HOT-SALE PRODUCT

Quality First, Safety Guaranteed