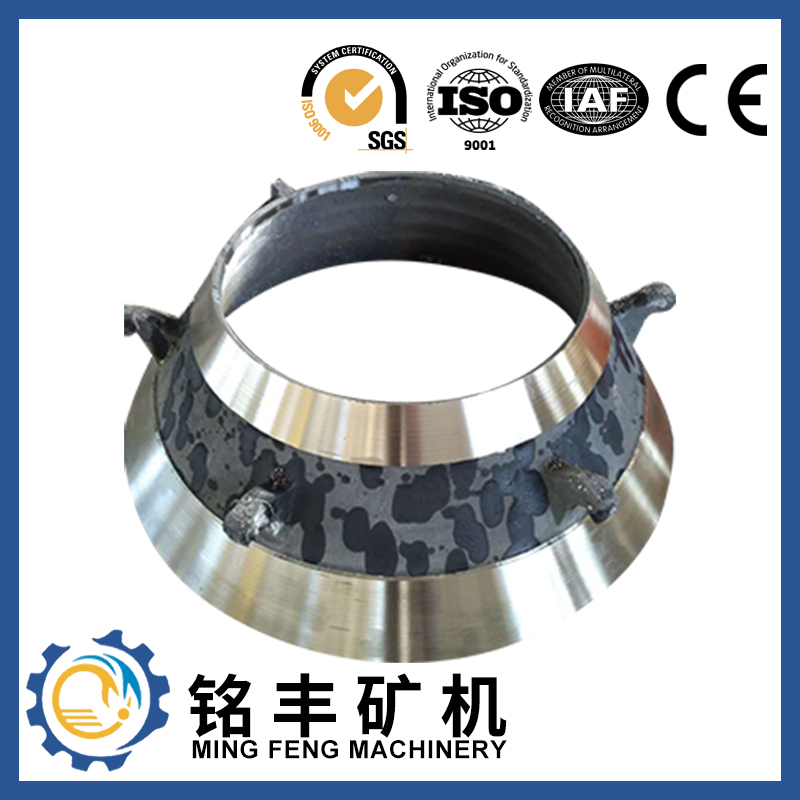

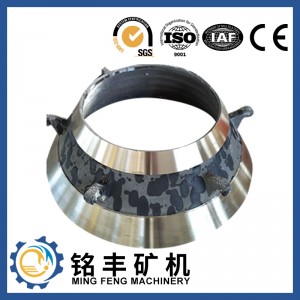

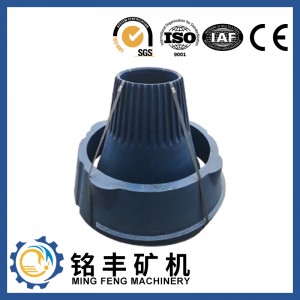

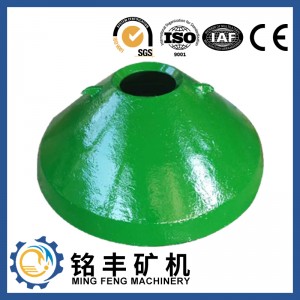

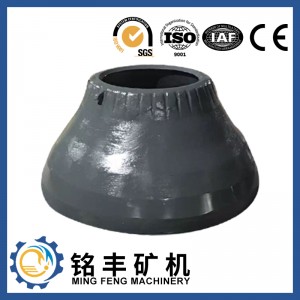

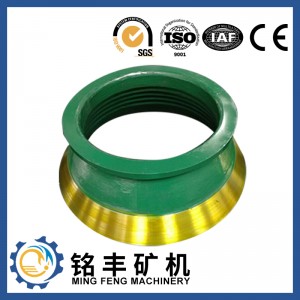

HPC160, HPC220, HPC315, HPC400 concave bowl liner for cone crusher

Application:

HPC series cone crusher with high-efficiency and hydraulic pressure was widely used in mining, concrete factory, sandstone making, etc. The machinery’s pressure resistance strength is under 350Mpa. And they are widely suitable for primary crushing of many kinds of mining and rock such as many kinds of ores, concrete, fireproof material, bauxite, quartzite, corundum, perlite, ironstone, basalt, etc.

Overview:

| Type | Bowl Liner, Concave Ring, Cone Liner,Mantle Liner | ||

| Main Model | HPC series | HPC160, HPC220, HPC315, HPC400 | |

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Cone Crusher | Certification | ISO 9001:2008 |

| Hardness | HB220~240 | Production Capability | More than 5000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Features and Benefits:

1. The new series of HPC cone crusher with high-efficiency and hydraulic pressure equipment is adopted three protecting equipment such as protecting oilcan, locking oilcan and hydraulic driving oilcan. They not only protect the machinery, but could deal with troubles without disassembly the parts.

2. The equipment also can adjust the size of final material. The machinery with high dependability operated very expediently.

3. The crushing chamber specially designed according to particles sink principal and its matching speed can sharply increase the crushing ratio, output and content percentage of cubical product in final crushed material.

4. In the special circumstances such as irons was feed into the crushing chamber together with the materials and there is a jam in the crushing chamber, the hydraulic equipment could open the cover automatically, then the products could output successfully. It greatly reduced the trouble of stopping the machine to output the products artificially. Which makes the maintenance more convenient and with low cost.

5. It is adjusted by hydraulic device and lubricated by the dilute oil. And with locking sleeve assembly, it can overcome the trouble of oil and water being mixed together.

6. The concave and mantle made by high manganese steel. Owing to the change of the concave’s style and the protect of the crushed products. The abrasion of the machine is reduced greatly and can last long compared with the old cone crusher.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed