Hot Selling for Jaw Crusher Toggle Plate Material - PEX-250×1200 jaw crusher – MING FENG MACHINERY

Hot Selling for Jaw Crusher Toggle Plate Material - PEX-250×1200 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PEX-250×1200 |

250×1200 |

210 |

20-60 |

330 |

37 |

25-60 |

7.7 |

Description:

Despite that the jaw crusher has been developed for many years, it is still widely used in fields of metallurgy, mining, chemical, construction, fireproof material, ceramics industry because of its simple structure, solidity, reliability, easy maintenance. It can be used to crush rocks with a fracture strength within 147-245MPa into coarse/medium/fine size. In order to meet the requirement of high crushing ratio and hardness of low carbon ferrochrome in fields of metallurgy, mining and construction nowadays, we have designed modern Jaw crusher.

It comprises the frame, the eccentric shaft, the grooved wheel, the flywheel, the mobile jaw, the side plate, the toggle plate, the captured spring, the fixed jaw plate and the mobile jaw plate, the safety device and the adjusting device, etc.

Working principle:

The motor drives the belt and the grooved wheel, and then makes the jaw move up and down through the eccentric shaft. When the jaw moves upwards, the angle between the liner plate and the jaw becomes larger, which will push the mobile jaw plate close to the fixed jaw plate, during which the material is crushed. When the mobile jaw moves downwards, the angle between the liner plate and the mobile jaw becomes smaller. The mobile jaw plate will leave the fixed jaw plate under the force the rod. The crushed material will drop from the discharge opening. With the motor rotating continuously, mass production can be realized.

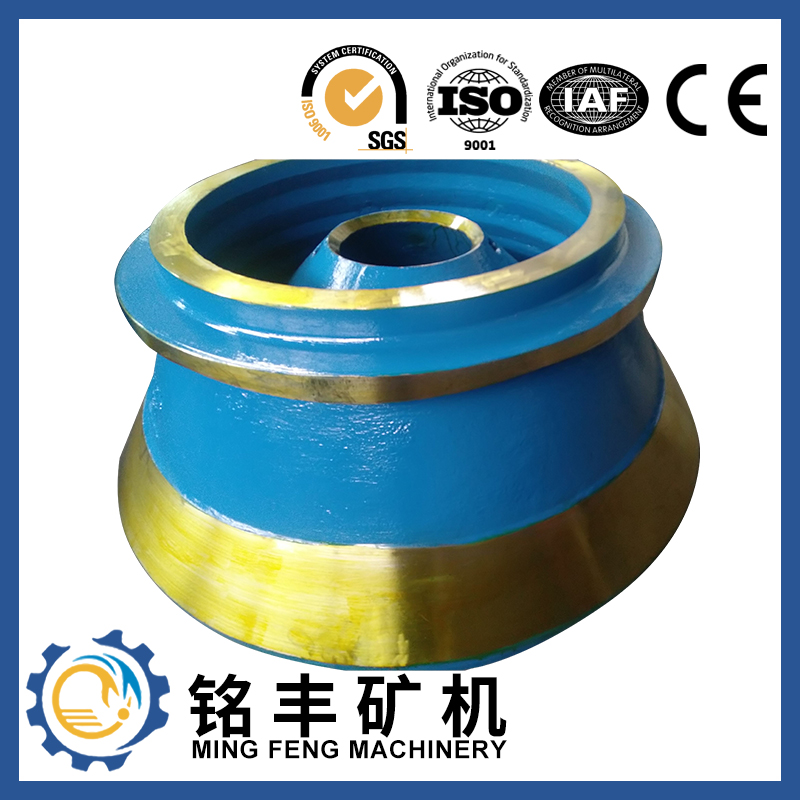

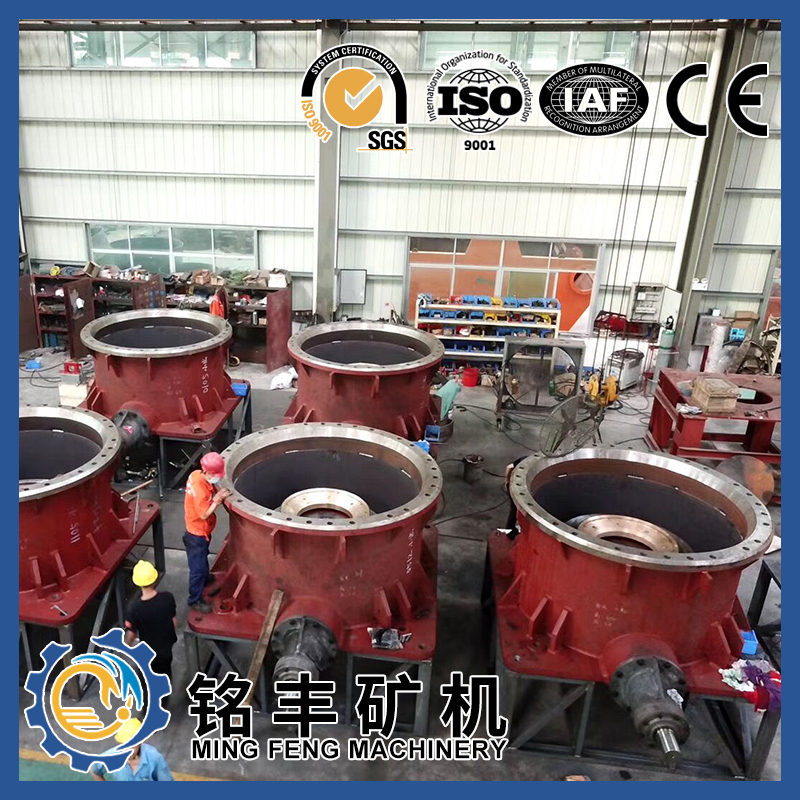

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Hot Selling for Jaw Crusher Toggle Plate Material - PEX-250×1200 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Armenia, Kyrgyzstan, Paraguay, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed