Hot sale Mn13% Rolling Mortar Wall - High Mn (Manganese) ceramic composite mantle/cone – MING FENG MACHINERY

Hot sale Mn13% Rolling Mortar Wall - High Mn (Manganese) ceramic composite mantle/cone – MING FENG MACHINERY Detail:

Description:

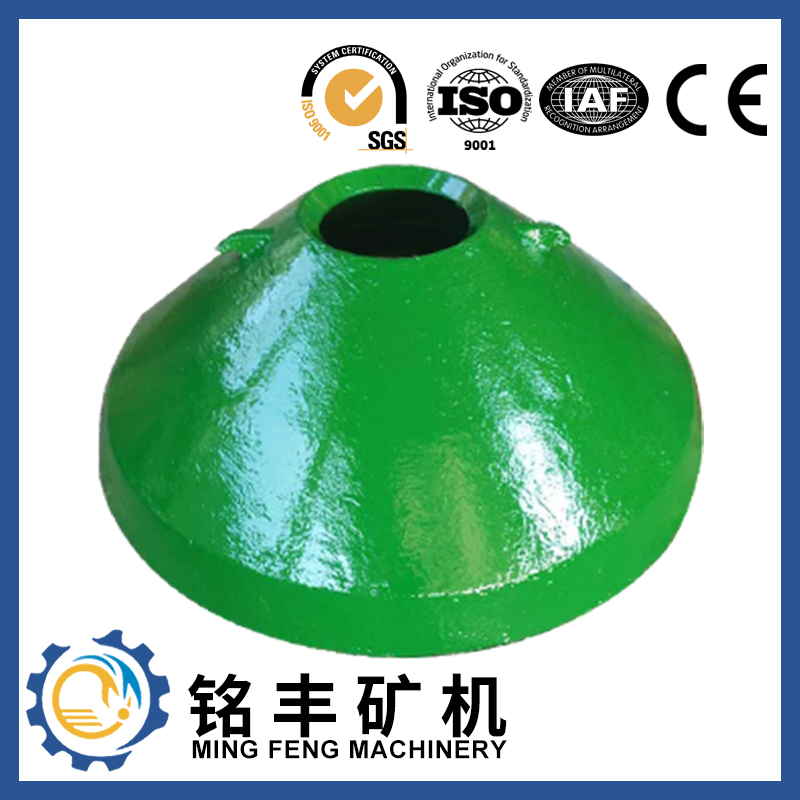

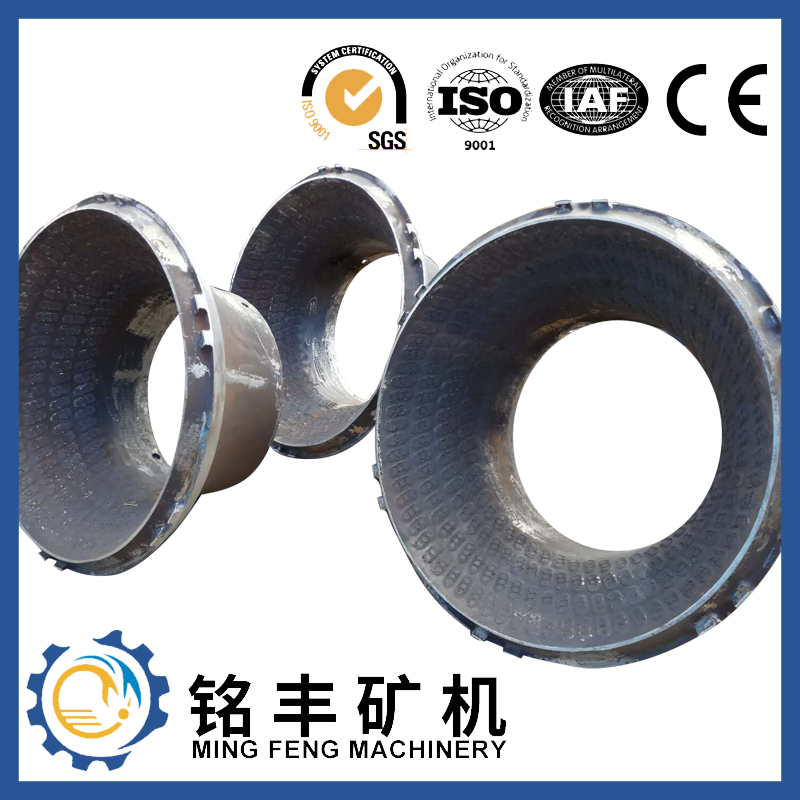

When Cone crusher works, eccentric sleeve rotates by motor through V-belt, big pulley, drive shaft, a small bevel gear, big bevel gear. crushing cone axis rotates and swing under the pressure of eccentric sleeve, make the cone sometime close to the mantle and sometimes far from it, so that the material in the ring fixed cone and fixed cone crushing cavity composed constantly under attack, squeezing and bending and breaking. After several extrusion, impact and bending, the material is crushed to the required size, and discharged from the lower part.

Applications:

Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

Product Benefits:

Compared with the general market products, our products smooth surface, accurate dimensions , high wear resistance and longer life. Direct sales by the company foundry, cost-effective products.

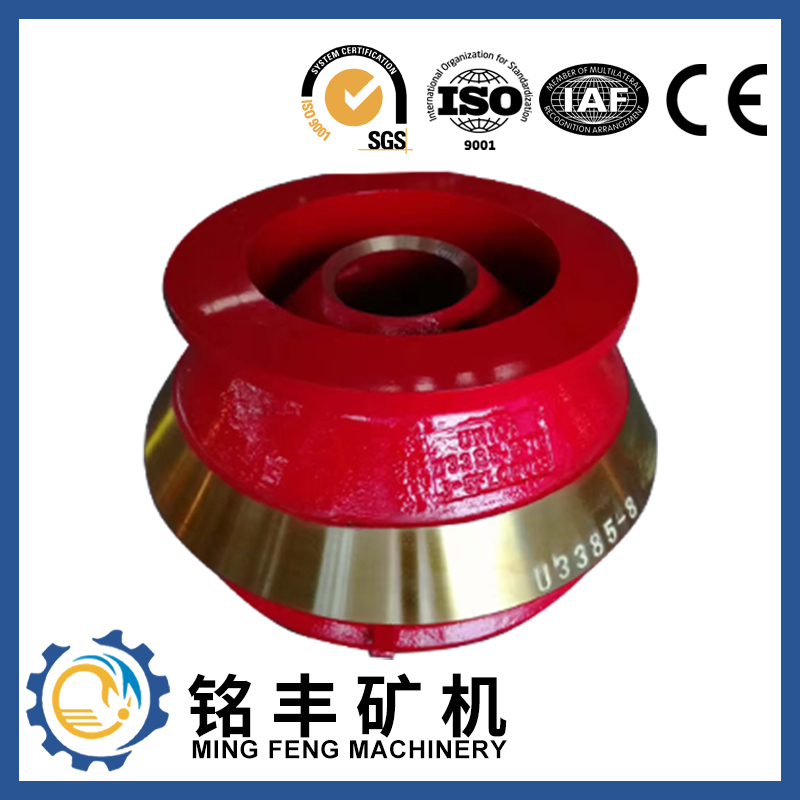

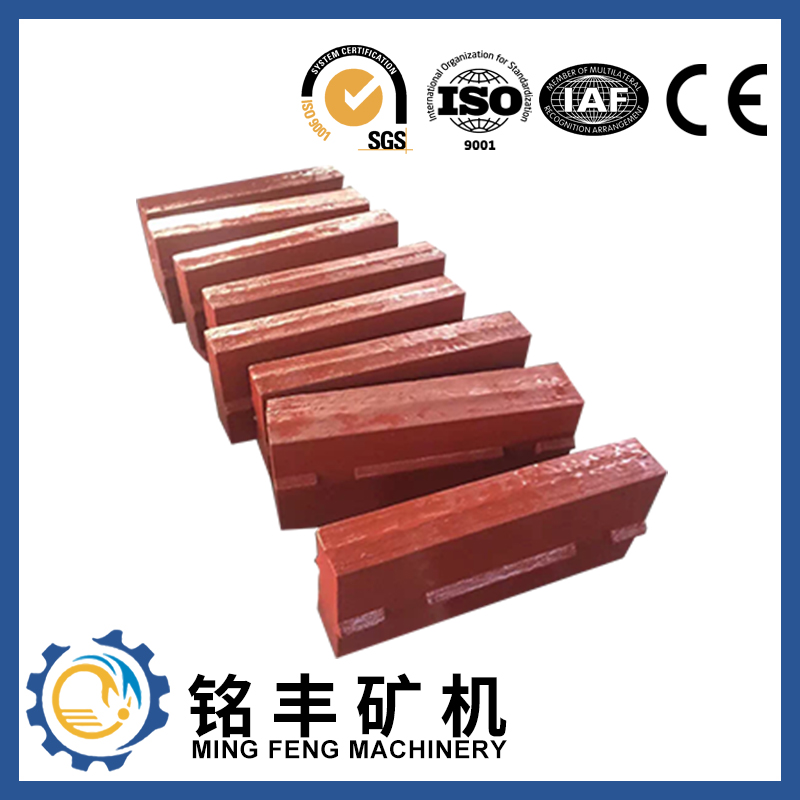

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Hot sale Mn13% Rolling Mortar Wall - High Mn (Manganese) ceramic composite mantle/cone – MING FENG MACHINERY , The product will supply to all over the world, such as: Grenada, Manchester, Nigeria, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for you in China. Of course, other services, like consulting, can be offered too.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed