Hot sale Metal Rc Mining Equipment - Hammer crusher – MING FENG MACHINERY

Hot sale Metal Rc Mining Equipment - Hammer crusher – MING FENG MACHINERY Detail:

Hammer Crusher Technical Data:

|

Model |

Speed |

Feed size |

Selected size |

Output |

Weight |

Power |

Overall Dimensions |

|

PC-400×300 |

1450 |

≤100 |

10 |

3-10 |

0.8 |

11 |

812×9827×85 |

|

PC-500×350 |

1250 |

≤100 |

15 |

5-15 |

1.2 |

18.5 |

1200×1114×1114 |

|

PC-600×400 |

1000 |

≤220 |

15 |

5-25 |

1.5 |

22 |

1055×1022×1122 |

|

PC-800×600 |

980 |

≤350 |

15 |

10-5 |

3.1 |

55 |

1360×1330×102 |

|

PC-800×800 |

980 |

≤350 |

15 |

10-60 |

3.4 |

75 |

1440×1740×1101 |

|

PC-1000×800 |

1000 |

≤400 |

13 |

20-75 |

7.9 |

115 |

3514×2230×1515 |

Description:

The roller crusher is a crushing equipment that uses a pair of round rolls or irregular rolls rotating in opposite direction for crushing. Its feed particle size is ≤ 30mm, and the processing capacity is 5-110 t/h.

Applicable materials:

The roller crusher can be used for medium and fine crushing of medium-hard and soft ores. It is generally suitable for crushing and sand-making of coal, raw coal, coal gangue, etc., so it can be applied in mining, metallurgy, building materials, coal mines and other fields.

Advantages:

1.The hammer is heavy-duty because of the wear-resistant alloy head.

2.Modern design and firm structure.

3.The sealed condition reduces pollution and powder releasing.

4.The plates that can be moved to change the distance between each other are very firm.

5.Having introduced advanced technologies, it has high efficiency and is environmentally friendly.

6.Stable and firm structure, and modern design.

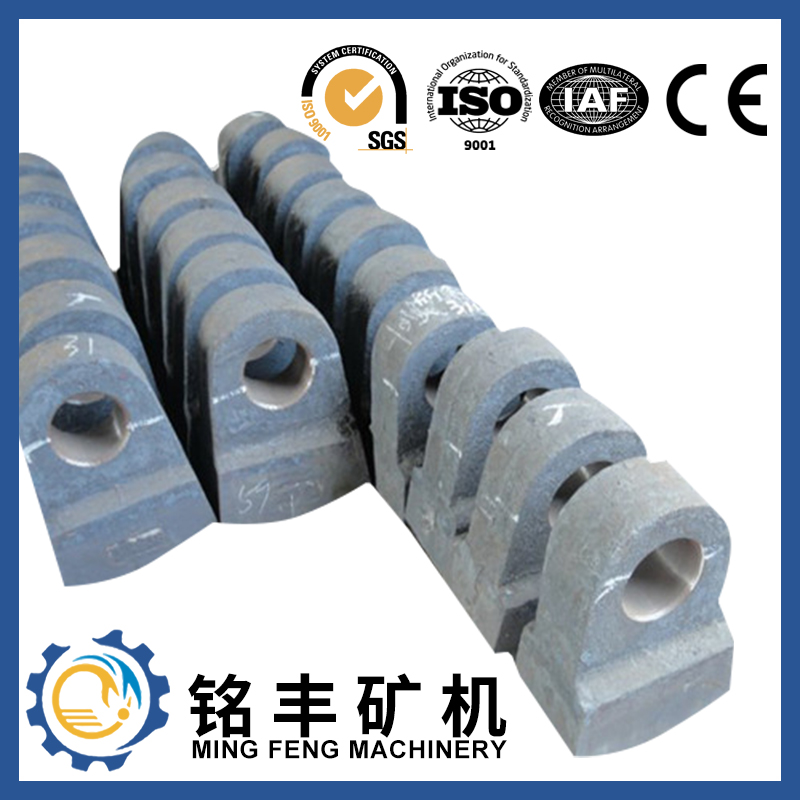

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Hot sale Metal Rc Mining Equipment - Hammer crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: French, Oman, Indonesia, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows Survive by good quality, Develop by keeping good credit. operation policy. Welcome all the clients old and new to visit our company and talk about the business. We are looking for more and more customers to create the glorious future.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed