Hot sale Factory Mining Equipment Rental Rates - PF-1214V impact crusher – MING FENG MACHINERY

Hot sale Factory Mining Equipment Rental Rates - PF-1214V impact crusher – MING FENG MACHINERY Detail:

Impact Crusher Technical Data:

|

Model |

Spec of Rotor |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Motor Power |

Weight |

Overall Dimensions |

|

PF-1214V |

Φ1250×1400 |

400×1080 |

350 |

130-180 |

132-160 |

20 |

2690×2688×2890 |

Descriptions:

An impact crusher, or impactor, is one of several types of crushing machines, including jaw crushers, hammermills, and cone crushers, that is manufactured for the purpose of processing raw materials, like concrete or asphalt, among many others, to reduce them in size.

Used in a wide variety of applications, including aggregate crushing, asphalt crushing, and concrete crushing, etc., an impactor is unique to its crusher counterparts in that it breaks apart rocks and stones by rapidly striking the material as opposed to utilizing a pressure force.

The mechanical structure of an impact crusher is defined by its rotor, the primary instrument for breaking apart material. The rotor is set among mounted plates, anvils, or aprons, inside a heavy housing; these aprons or anvils serve to bear the impact of the materials being processed and further break them apart.

Advantages:

1. Durable and heavy-duty plates.

2. Durability and longevity

3. Wide range of applications.

4. 24-hour parts and service

5. Highest productivity and profits

6. High resale value

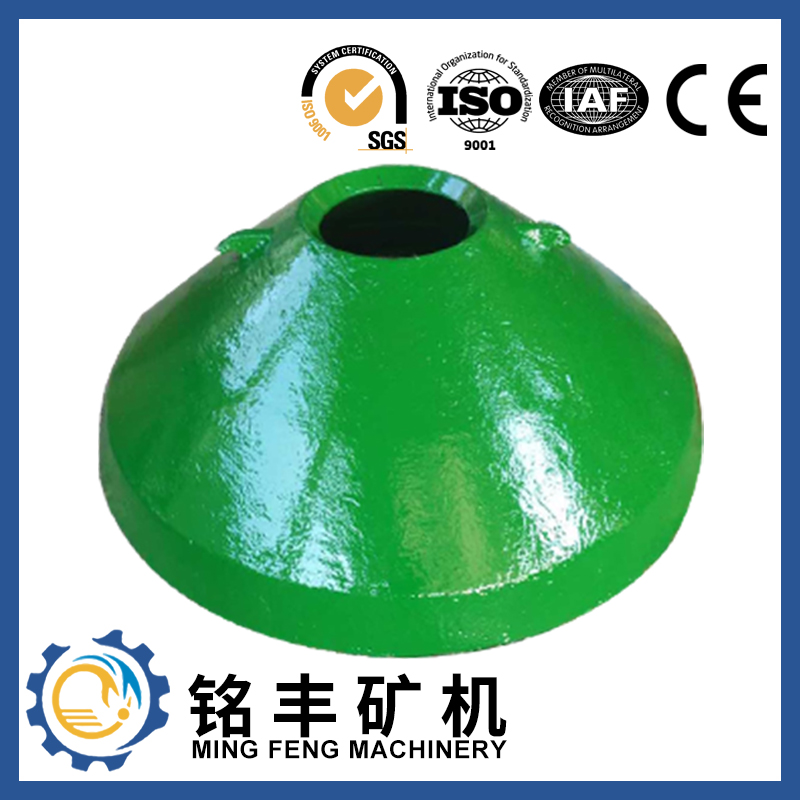

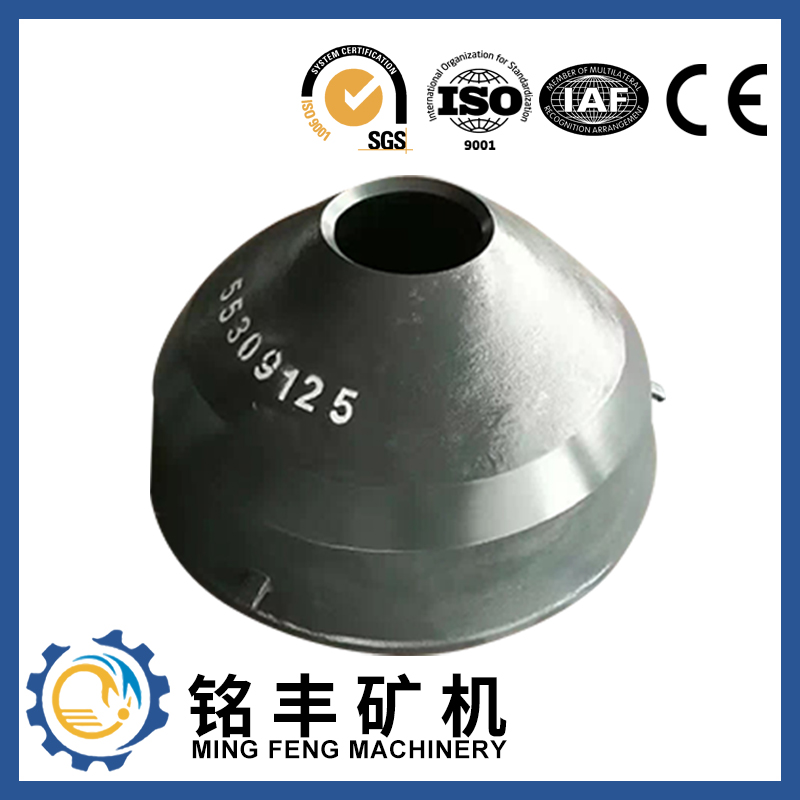

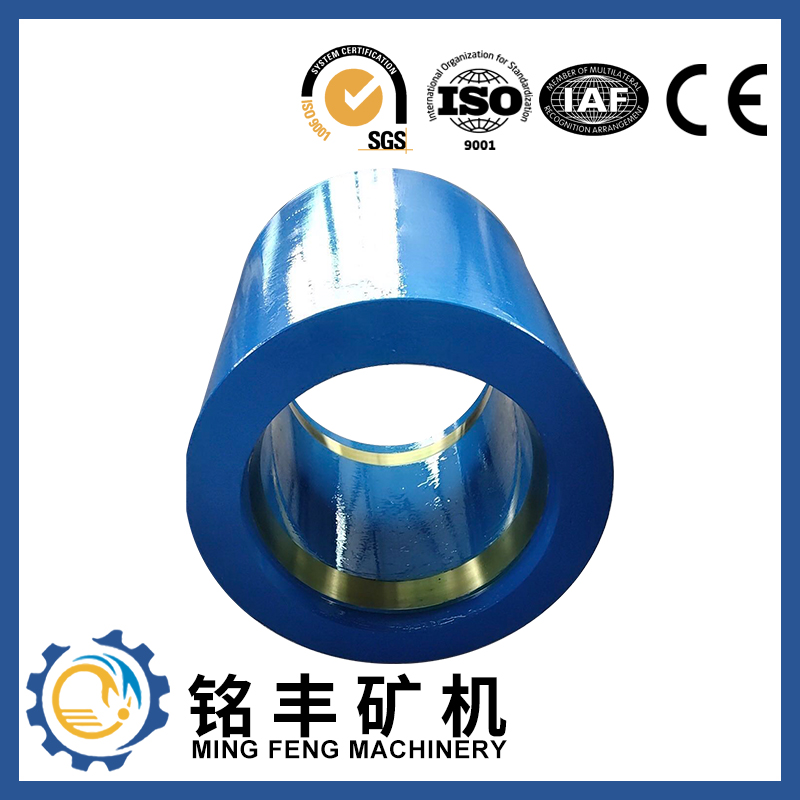

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for Hot sale Factory Mining Equipment Rental Rates - PF-1214V impact crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Israel, Morocco, Nigeria, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed