High quality market price forging bucket teeth

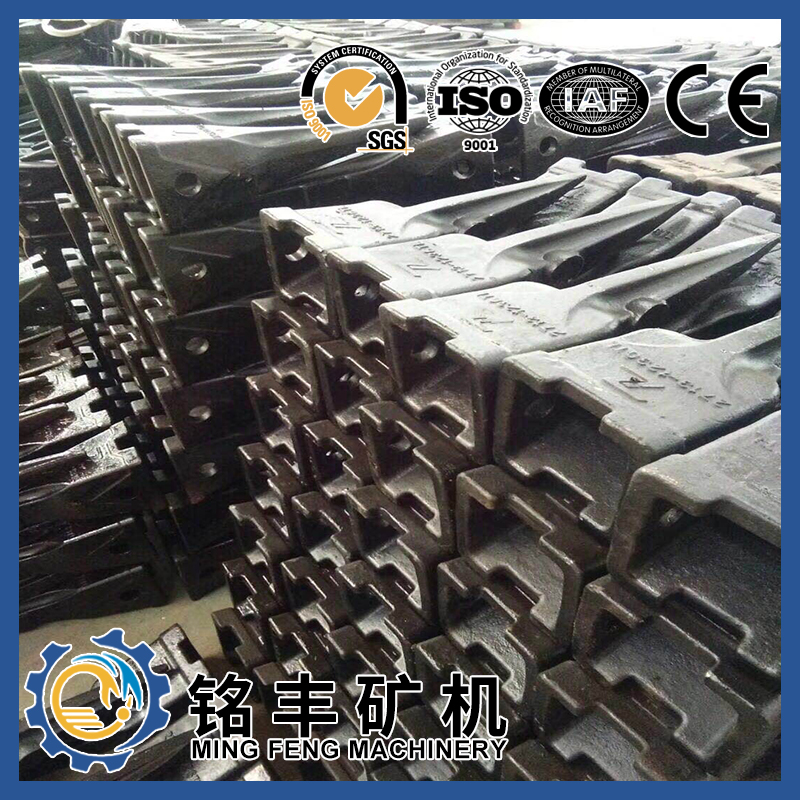

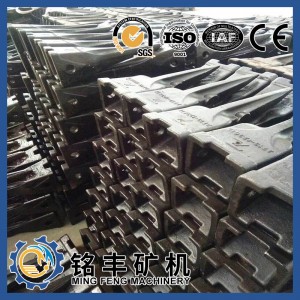

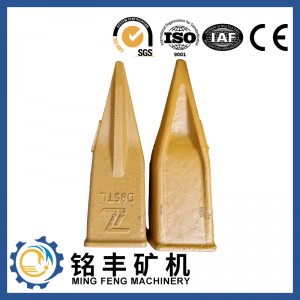

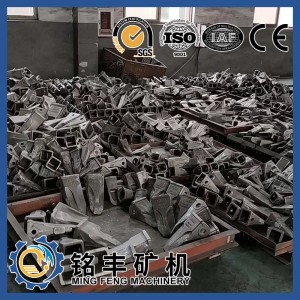

Forging Bucket Teeth

1. Bucket Teeth Material Available: Carbon steel, Alloy steel(high Manganese steel, high Chromium steel, etc)

2. Moulding processing Available: Green Sand or Resin Sand Casting.

3. The bucket teeth are under Quenching and tempering treatment. Our bucket teeth have good physical

Performance and can be used for a long time.

4. The whole process from casting to heat treatment is strictly inspected by our professional workers to ensure the quality. The hardness of our Bucket Teeth & Adapters are up to HRC48-53, with excellent elongation and tensile strength, so very suitable for many different hard working conditions.

5. Our products are being exported throughout the world. Our sales volume increasingly grows and our products have gained many customers’ recognition for high quality. We exporte to North- America, Western Europe, Eastern Europe, Middle- East, Asian areas and countries.

6. Technical infomation:

Teeth

Hardness HB 470–540

Yield point 1340Re -N/mm2

Tensile strength 1690RM -N/mm2

Elongation 9%

Resilience (-20oC) 17J

Adapter

Hardness HB 380–430

Customer’s drawings and/or samples are both acceptable for business.

Parameter list of Mechanical Properties of Wear-resistant Alloy Steel

| impact toughness | HRC | Extension | tensile strength αβ(Mpa) |

Yield Strength αε(Mpa) |

| 20℃≥20J -40℃≥14J | 48-52 | ≥5 | 1600 | 950 |

Ordinary alloy steel mechanical performance parameter table

| impact toughness | HRC | Extension | tensile strength αβ(Mpa) |

Yield Strength αε(Mpa) |

| 20℃≥20J -40℃≥13J | 46-50 | ≥4 | 1450 | 900 |

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed