High Quality for Hp300 Mantle - PF-1210V impact crusher – MING FENG MACHINERY

High Quality for Hp300 Mantle - PF-1210V impact crusher – MING FENG MACHINERY Detail:

Impact Crusher Technical Data:

|

Model |

Spec of Rotor |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Motor Power |

Weight |

Overall Dimensions |

|

PF-1210V |

Φ1250×1050 |

400×1080 |

350 |

70-120 |

110-132 |

15.2 |

2696×2338×2890 |

Description:

The core of the impact crusher is the fast-rotating rotor, which operates in a housing protected by wear plates. The crushing process and thus the product can be significantly influenced by changing the rotor speed as well as by adjustable impact aprons in the housing.

Working principle:

During operation, the rotor driven by the motor performs high-speed rotation. The plates installed on the rotor collide with the material. Afterwards the material will be thrown onto the impact plate for secondary crushing. The material will be crushed in different chambers with sequence until the size of the crushed material reaches required sizes. The finished products will be discharged through the discharge opening.

Advantages:

1. Large feed opening

2. Robust design

3. Powerful rotors

4. Excellent crushing performance

5. Largely standardized and interchangeable wear parts

6. Low maintenance requirements

7. Quick and simple blow bar replacement

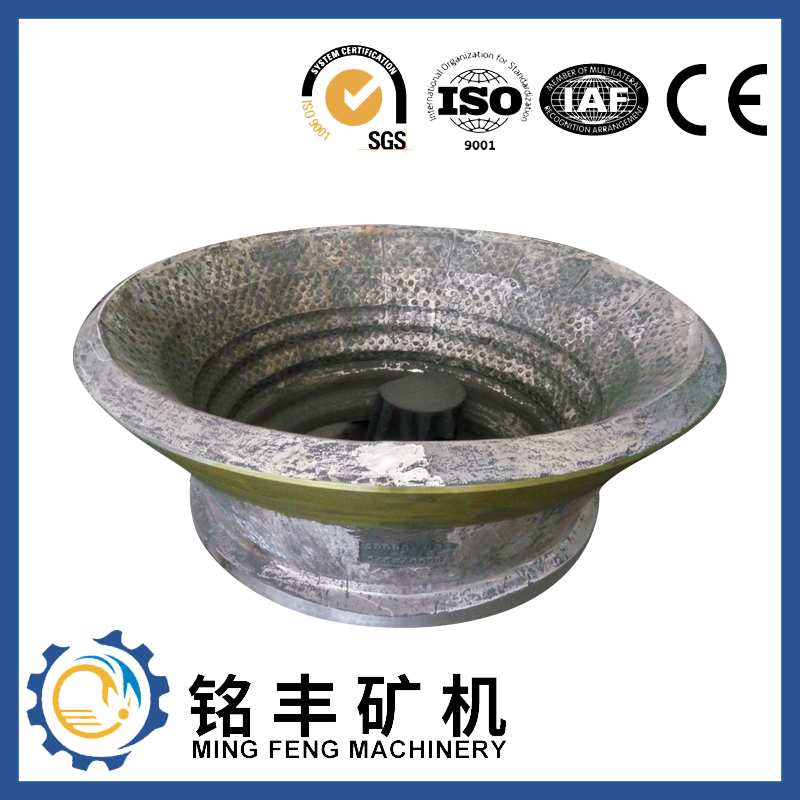

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for High Quality for Hp300 Mantle - PF-1210V impact crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Nigeria, Rio de Janeiro, Qatar, Wide selection and fast delivery to suit your needs! Our philosophy: Good quality, great service, keep improving. We've been looking forward that more and more oversea friends join in our family for further development near the future!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed