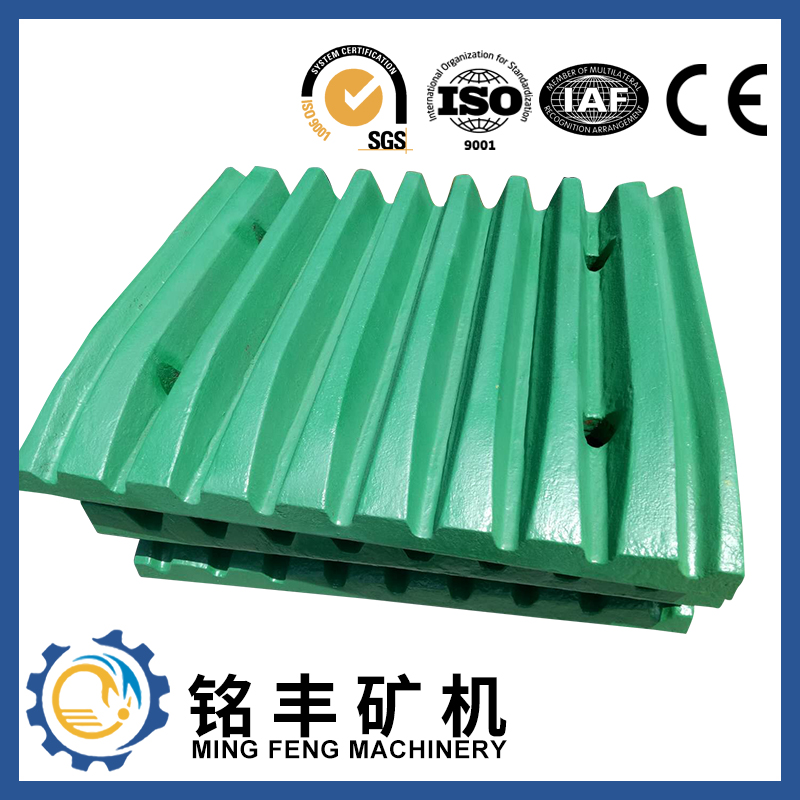

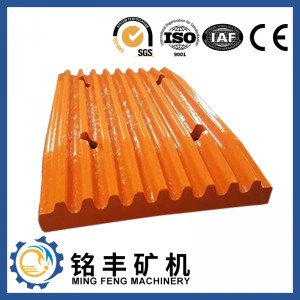

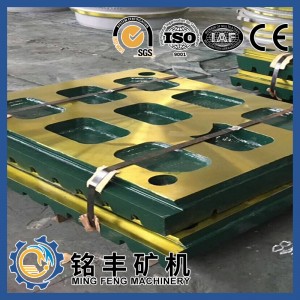

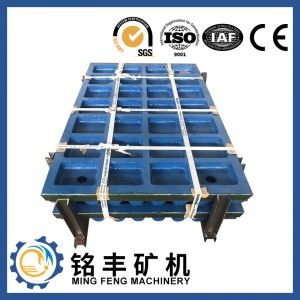

High manganese steel crusher jaw plate wear resistant plate

Overview:

| Type | movable, swing jaw, fixed jaw plate | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | jaw Crusher | Certification | ISO 9001:2008 |

| Hardness | HB220~240 | Production Capability | More than 50000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

When the wearing of the jaw plates is severe, it is a known fact that crusher performance is not ideal, because the empty spaces between the teeth are reduced, encagement happens frequently, the crushing angle is changed or, in other words, production is affected.

This means that, a cost-benefit analysis for changing the worn jaw plate should be seriously considered, because at a certain point, the difference in production justifies the investment in a new part. We have also observed users crushing even with cracked and perforated jaw plates, without carrying out the correct control and cost x production analysis.

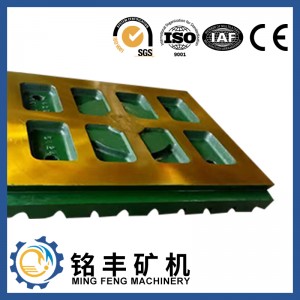

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1. We offer a variety tooth profiles and surface shapes;

2. We extend the service life of the jaw dies;

3. The fitting surfaces on all of our jaws are machine finished to ensure the best possible fit;

4. We provide more competitive prices.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed