High manganese shanbao cone crusher spare parts

Overview:

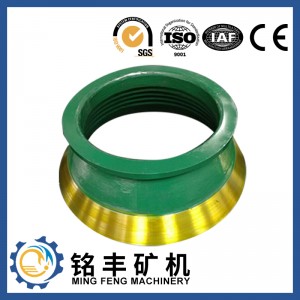

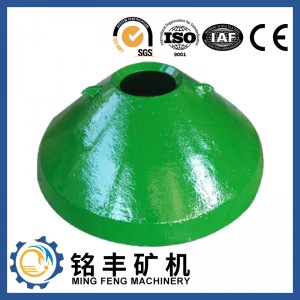

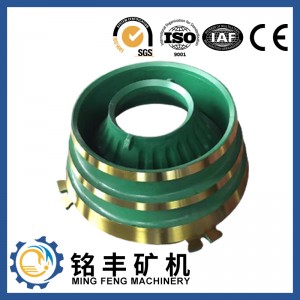

| Type | Bowl Liner, Concave Ring, Cone Liner,Mantle Liner | ||

| Main Model | PY series | PYB/PYD600, PYB/PYZ/PYD900, PYB/PYZ/PYD1200, PYB/PYZ/PYD1750 | |

| PYF series | PYF900,PYF1300,PYF1600,PYF2100 | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Cone Crusher | Certification | ISO 9001:2008 |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High level | Experience | Over 30 years |

Production quality testing:

1.Direct-reading Spectrum Instrument

2.Ultrasonic Inspection

3.Metallographic Analysis

4.Magnetic Particle Inspection

5.Mechanical Properties Inspection

Description:

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.

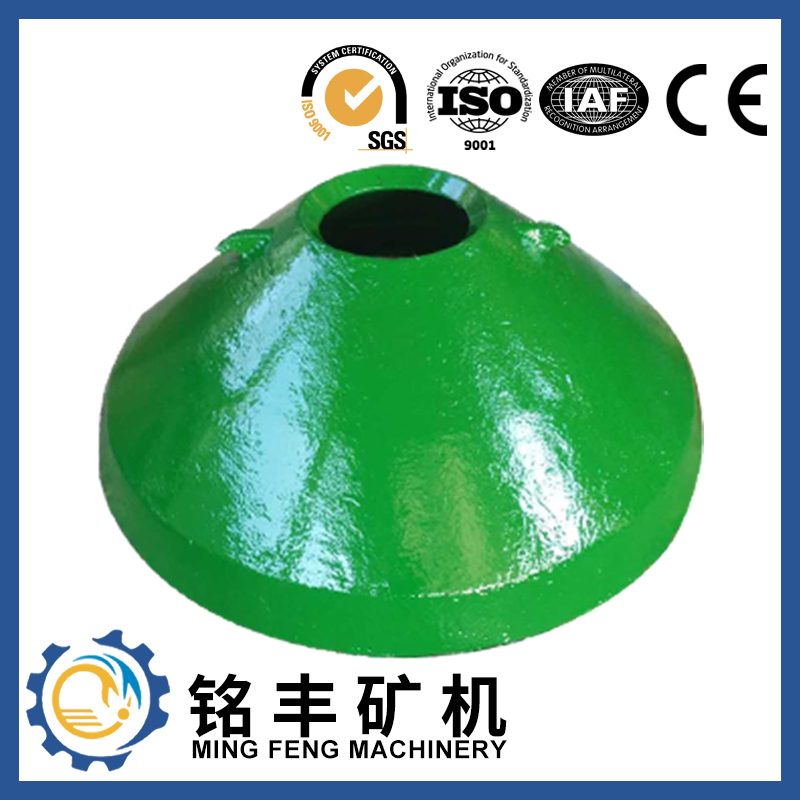

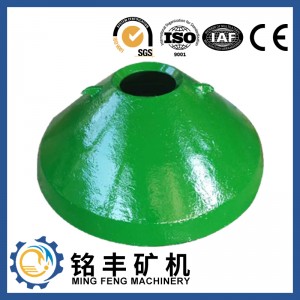

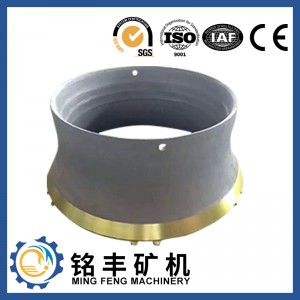

The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head. And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher.

We offer cone crusher mantles and bowl liners in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%.

Applications:

Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

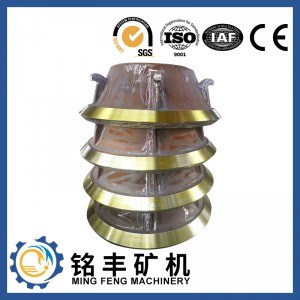

Cone Crusher Parts:

Ming Feng mainly deals in various brands of cone crusher parts, concave, mantle, eccentric bushing, step washer and other wear-resistant alloy parts.

Advantages:

1. Accurate dimensions, assure validity and suitability as per original parts number and drawing

2. Make your cone crusher experience less downtime

3. More economical, save your cost 40-60%

4. Advanced manufacturing technology, produce strictly according to original process flow & original drawings.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed