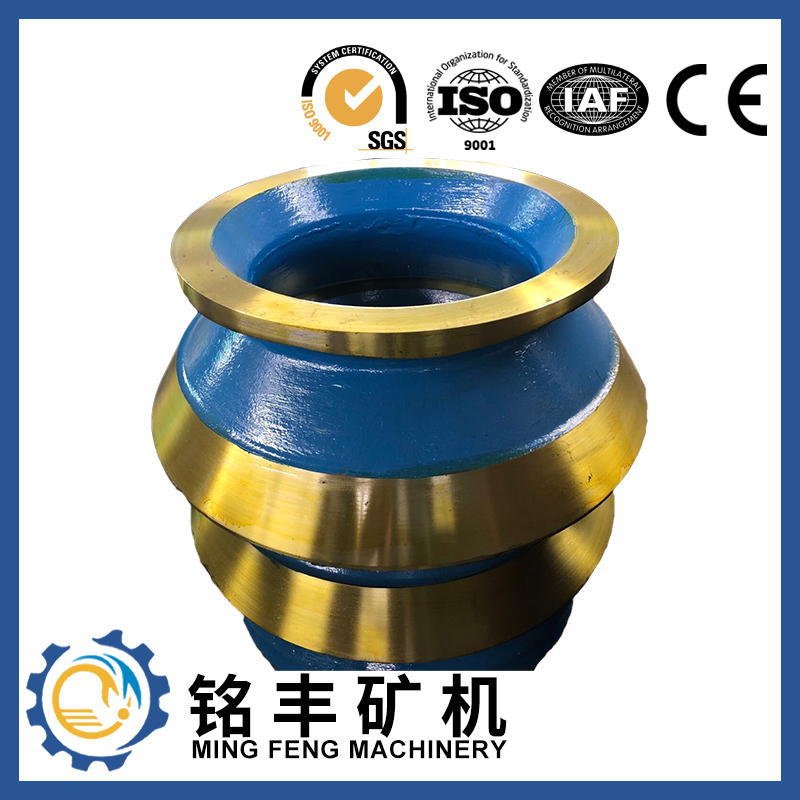

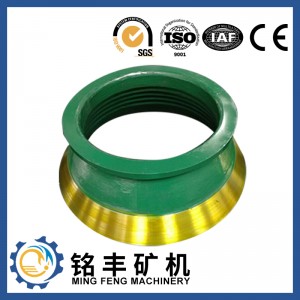

High manganese cone crusher parts

Ming Feng Wear Parts Foundry was built in the early stages of the reform and opening. It is a professional wear-resistant parts manufacturers who condenses the effort of several generations.

High Manganese series

–Wear Parts for Mining equipment

Main application for high wear resistance use such as Jaw crusher plate, Cone crusher bowl liner, Impact crusher lining board,Ball mill liner and the chain links for Dredge ect.

Overview:

| Type | Bowl Liner, Concave Ring, Cone Liner,Mantle Liner | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Cone Crusher | Certification | ISO 9001:2008 |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High level | Experience | Over 30 years |

Description:

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.

The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head. And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher.

We offer cone crusher mantles and bowl liners in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%.

Our advantage:

High Manganese Casting wear parts processed by our foundry, using special heat-treatment process.It has a service life 10% longer than those made of traditional high manganese steel.Our products with good performance in different working condition can greatly decrease the time of examination & repair and the use-cost.

| High Manganess Casting Material Chemical Composition | |||||||

| Code Elem. | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

HOT-SALE PRODUCT

Quality First, Safety Guaranteed