Fast delivery Rod Mill For Sale - 40 60 80 100 120 high/medium/low chrome ball mill liners – MING FENG MACHINERY

Call us for information: Tel: +86-18973821771

Fast delivery Rod Mill For Sale - 40 60 80 100 120 high/medium/low chrome ball mill liners – MING FENG MACHINERY Detail:

Overview:

| Type | Crusher liner board, lining plate | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Grinding ores | Quartz, Gold ore, Cement clinker, etc. |

| Machine Type | Ball Mill Liner | Certification | ISO 9001:2008 |

| Main Materials | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Technical Parameters

| Chemical Components | ||||||||

| Type

|

Chemical components | |||||||

| C | Si | Mn | Cr | Mo | Cu | P | S | |

| Low-Cr | 1.8-3.3 | ≤1.5 | 0.3-1.5 | 1-3 | ≤1.0 | ≤0.8 | ≤0.10 | ≤0.10 |

| Medium-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 4-9 | ≤1.5 | ≤0.8 | ≤0.10 | ≤0.10 |

| High-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 10-18 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.06 |

| Superhigh-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 19-35 | ≤2.0 | ≤1.2 | ≤0.10 | ≤0.06 |

| Nominal Diameter | Diameter Tolerance | Weight of Single Ball In Average | |

| (mm) | (Inch) | (mm) | (g) |

| 20 | 0.75” | +2 -1 |

32 |

| 25 | 1” | 64 | |

| 30 | 1.25” | 110 | |

| 40 | 1.5” | 263 | |

| 50 | 2” | 513 | |

| 60 | 2.5” | +3 -2 |

888 |

| 70 | 2.75 | 1410 | |

| 80 | 3.25” | 2104 | |

| 90 | 3.5” | 2996 | |

| 100 | 4” | 4110 | |

| 110 | 4.5” | +4 -2 |

5457 |

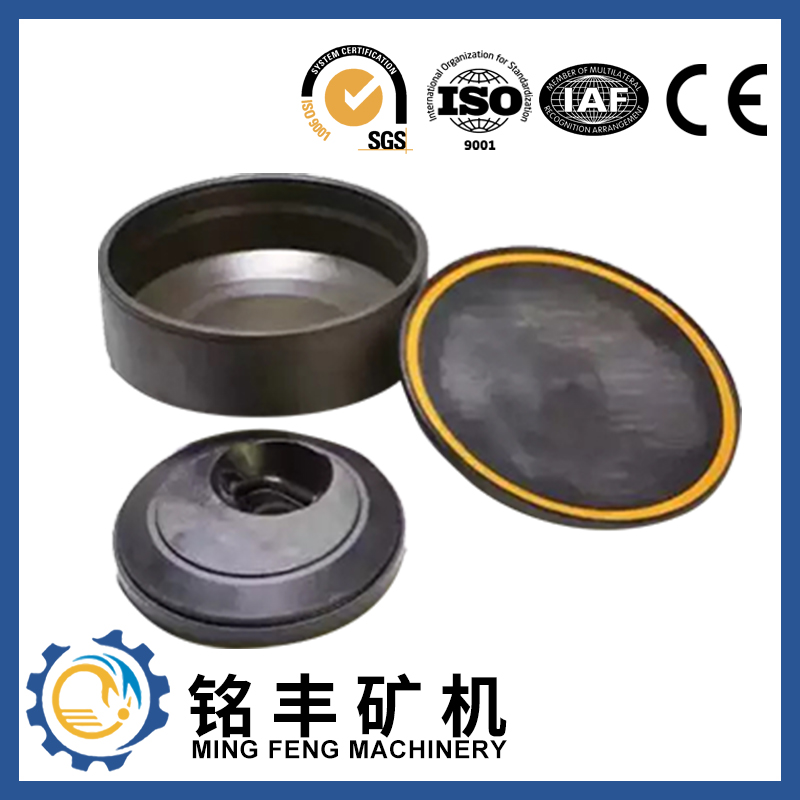

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

As a way to finest meet up with client's wants, all of our operations are strictly performed in line with our motto High Quality, Aggressive Price, Fast Service for Fast delivery Rod Mill For Sale - 40 60 80 100 120 high/medium/low chrome ball mill liners – MING FENG MACHINERY , The product will supply to all over the world, such as: Provence, Naples, moldova, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

Write your message here and send it to us

HOT-SALE PRODUCT

Quality First, Safety Guaranteed