Factory wholesale Hammer Crusher Pdf - High chrome casting Iron crusher wear part hammer – MING FENG MACHINERY

Factory wholesale Hammer Crusher Pdf - High chrome casting Iron crusher wear part hammer – MING FENG MACHINERY Detail:

Overview:

| Place of Origin | Hunan, China | Content of Mn | 26% |

| Product name | Hammer | Machine Type | Crusher |

| Material | hard metal; carbide; cemented carbide; kentanium; wimet; sintered-carbide; hard alloy; carbide alloy Cr20Mn2,Cr26Mn2 | ||

| Processing Type | Casting | Application | Ore Mining |

| Certification | ISO9001 | Testing Method | Hardness test and flaw detector test |

| Control | Spectrometer chemical analysis and control while producing | ||

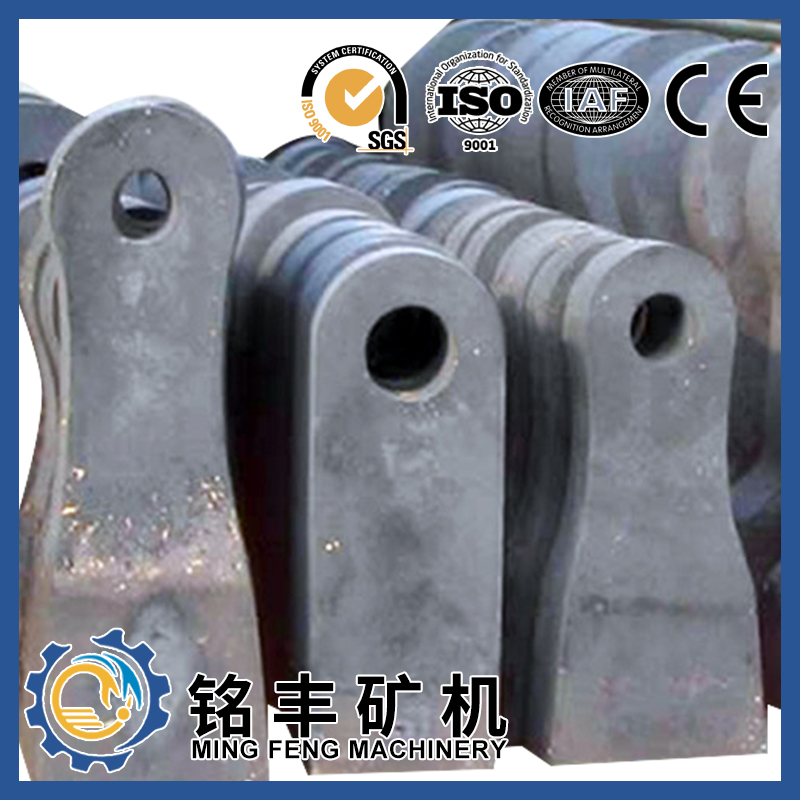

High chrome hammers: material is mainly for Cr20/Cr26. The serving life is 5~8 times of normal forging hammers. Those hammers mainly used in hammer crusher for cement plants, gravel firms, coal gangue treatment plants and block plants.

High chrome hammers: while casting, we not only add molybdenum, vanadium, titanium, nickle, boron and other rare alloy elements. Meantime, we specially adopt variety of alloy modifier to strengthen the matrix. Those hammers use refining, vacuum casting, directional solid and etc technical’s’ to increase the grain refinement and make the hammers performance achieve the best performance.

| High Chrome Crusher Hammer head: | |

| Material | Cr20Mn2,Cr26Mn2 |

| Control | Spectrometer chemical analysis and control while producing |

| Molding Process | Water-glass sand casting or lost form casting |

| Melting facility | Medium frequency electric furnace |

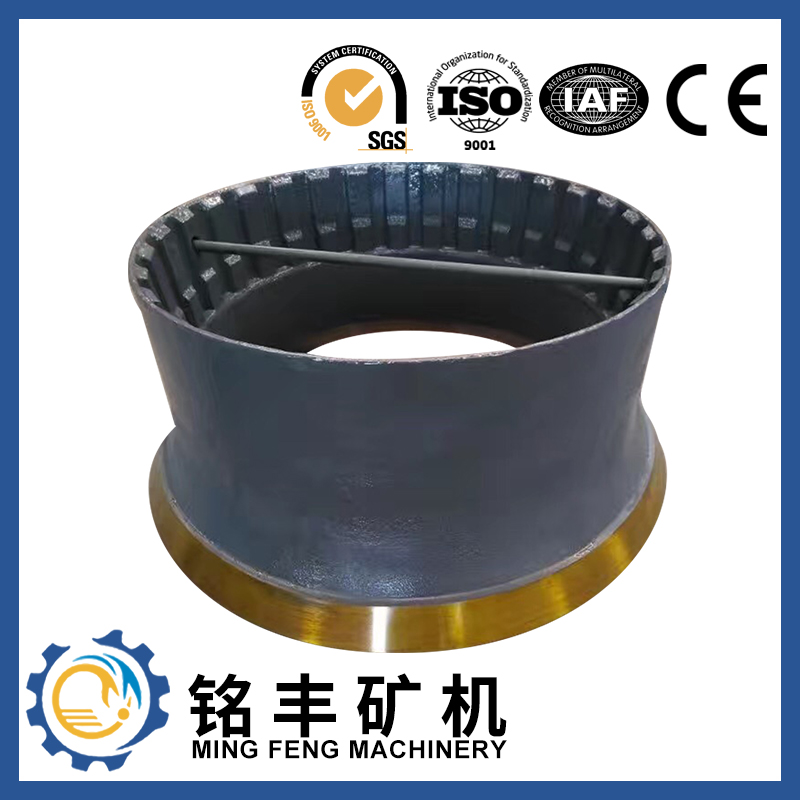

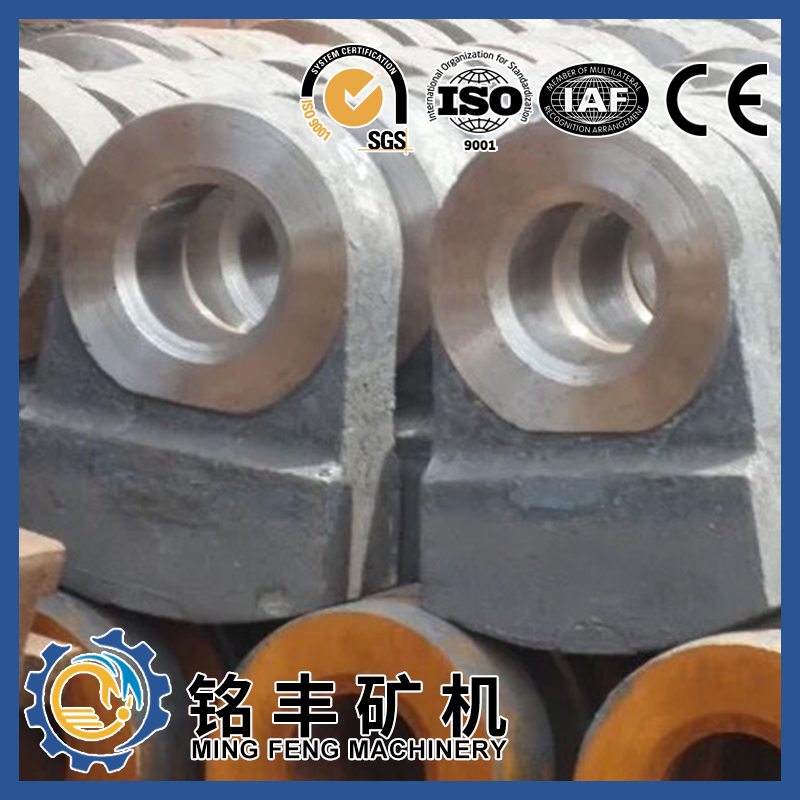

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

we can offer high quality products, competitive price and best customer service. Our destination is You come here with difficulty and we give you a smile to take away for Factory wholesale Hammer Crusher Pdf - High chrome casting Iron crusher wear part hammer – MING FENG MACHINERY , The product will supply to all over the world, such as: United Kingdom, Jeddah, Madras, We are proud to supply our products and solutions to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed