Factory source Apsm-1615 Blow Bar - 2PG-750X500 roll crusher – MING FENG MACHINERY

Factory source Apsm-1615 Blow Bar - 2PG-750X500 roll crusher – MING FENG MACHINERY Detail:

|

Specification |

Max Feed Edge |

Discharge Size |

Production |

Power |

Weight |

|

2PG-750X500 |

≤40 |

2–20 |

15-40 |

37 |

12250 |

Description:

The double-roller crusher is one of the crushers produced by our company for coarse/fine crushing. It is widely used in fields of cement making, chemical engineering, waterpower, metallurgy, construction, fire-proof material making, etc. It is suitable to deal with medium-hardness materials like limestone, pebble, clinker, coke, etc. The material to be crushed should have fracture strength less than 300MPa and humidity less than 35%.

Working principle:

During operation, the two rollers, driven by the motor through the V-belt, rotate in the opposite direction. The material will be crushed by the rollers after passing the feed opening and then be discharged from the base. The wedge-shaped device or washer between the rollers is adjustable. At the top of the wedge-shaped device, there is a bolt for adjusting. When the wedge-shaped device is pulled up by the bolt, the rollers will leave the fixed wheel. In the case, particles obtained become larger. While the wedge-shaped device moves downwards, the distance between the rollers becomes short under the influence of pressed springs. In the case, particles obtained become smaller. By increasing/decreasing the number or thickness of the washer, larger/smaller particles can also be obtained.

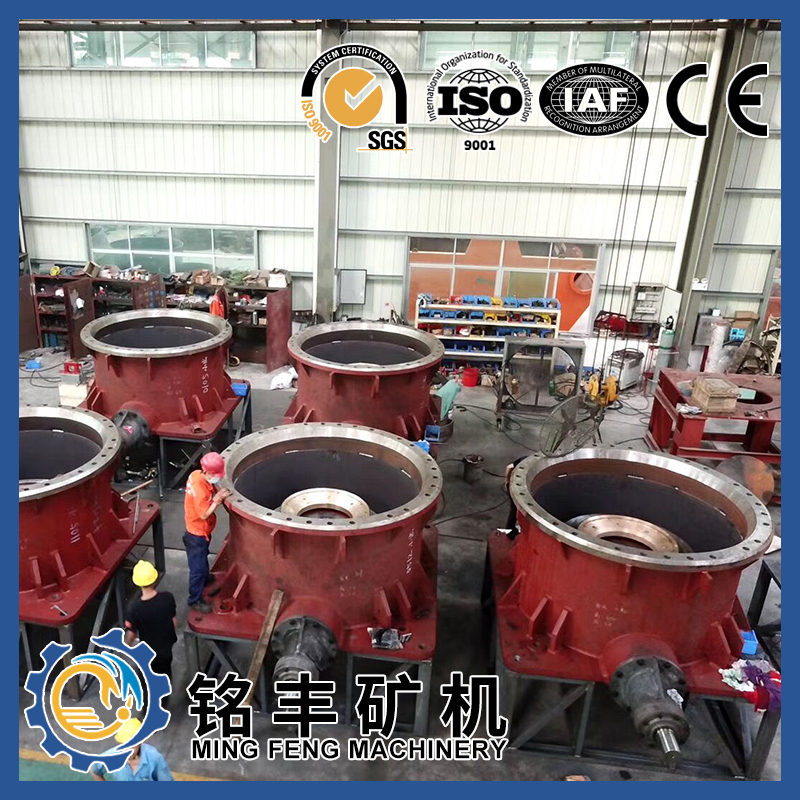

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable digital goods for Factory source Apsm-1615 Blow Bar - 2PG-750X500 roll crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Munich, Estonia, Brunei, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that customer first and committed to helping customers expand their business, so that they become the Big Boss !

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed