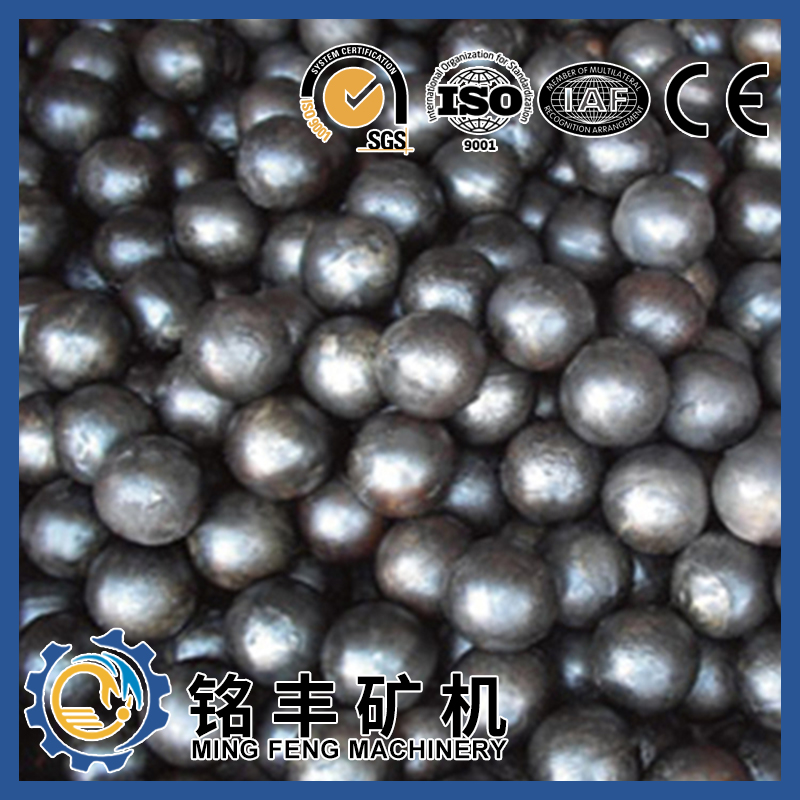

Factory Cheap Hot Rod Mill Parts - Casting steel grinding ball – MING FENG MACHINERY

Factory Cheap Hot Rod Mill Parts - Casting steel grinding ball – MING FENG MACHINERY Detail:

Overview:

| Type | Crusher liner board, lining plate | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Grinding ores | Quartz, Gold ore, Cement clinker, etc. |

| Machine Type | Ball Mill Liner | Certification | ISO 9001:2008 |

| Main Materials | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

The environment in primary ball milling can best be described by giving equal considerations to both impact and abrasive conditions. The relatively large ball sizes employed [3″ – 4″ (75 – 100 mm)] contribute a significant impact component to the overall wear. The number of impacts in primary ball mills are far more frequent but have less magnitude than those experienced in SAG mills. The increased frequency is due to the Increase in charge volume (35 – 40% versus 5 – 10%), higher mill speeds, and the larger number of balls per unit charge weight. The lower impact forces are due to a combination of both smaller ball masses and lower drop heights resulting from the use of smaller balls and smaller mill diameters, respectively.

The feed ore in primary grinding mills is typically very abrasive owing to its particle size, shape, and mineralogy. Wear speeds approaching or exceeding 20 µm/hr. have been measured for very abrasive Au. Cu, and Mo ores, while wear speeds on the order of 10-15 µm/hr. have been encountered in softer primary ores.

Steel grinding media used in primary grinding must be designed for maximum abrasive wear resistance while maintaining good toughness. Toughness is particularly important in grate discharge mills where pulp levels at the discharge end of the mill can approach zero.

Technical Parameters

| Chemical Components | ||||||||

| Type | Chemical components | |||||||

| C | Si | Mn | Cr | Mo | Cu | P | S | |

| Low-Cr | 1.8-3.3 | ≤1.5 | 0.3-1.5 | 1-3 | ≤1.0 | ≤0.8 | ≤0.10 | ≤0.10 |

| Medium-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 4-9 | ≤1.5 | ≤0.8 | ≤0.10 | ≤0.10 |

| High-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 10-18 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.06 |

| Superhigh-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 19-35 | ≤2.0 | ≤1.2 | ≤0.10 | ≤0.06 |

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Factory Cheap Hot Rod Mill Parts - Casting steel grinding ball – MING FENG MACHINERY , The product will supply to all over the world, such as: Uruguay, New Zealand, Italy, Due to the changing trends in this field, we involve ourselves into products trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality products within stipulated time.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed