Excellent quality Sandvik Blow Bar - PE-800×1060 jaw crusher – MING FENG MACHINERY

Excellent quality Sandvik Blow Bar - PE-800×1060 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PE-800×1060 |

800×1060 |

650 |

85-143 |

250 |

110 |

100-200 |

30 |

Description:

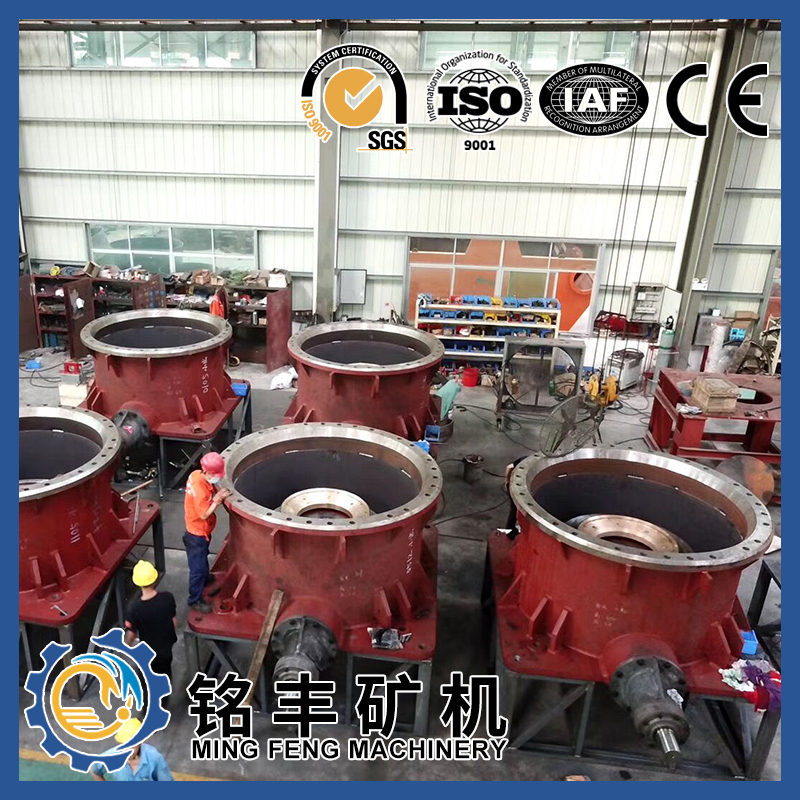

Jaw crushers are heavy duty machines and hence need to be robustly constructed. The outer frame is generally made of cast iron or steel. The jaws themselves are usually constructed from cast steel. They are fitted with replaceable liners which are made of manganese steel, or Ni-hard (a Ni-Cr alloyed cast iron). Jaw crushers are usually constructed in sections to ease the process transportation if they are to be taken underground for carrying out the operations.

It comprises the frame, the eccentric shaft, the grooved wheel, the flywheel, the mobile jaw, the side plate, the toggle plate, the captured spring, the fixed jaw plate and the mobile jaw plate, the safety device and the adjusting device, etc.

Advantages:

1.Flexible discharge opening setting

2.Stable performance and low operating cost

3.Simple Structure, Convenient Repair

4. High resistance to friction, abrasion and compression with longer operating life span.

5. Rigid one-piece fabricated base frame is reinforced for unmatched durability and strength

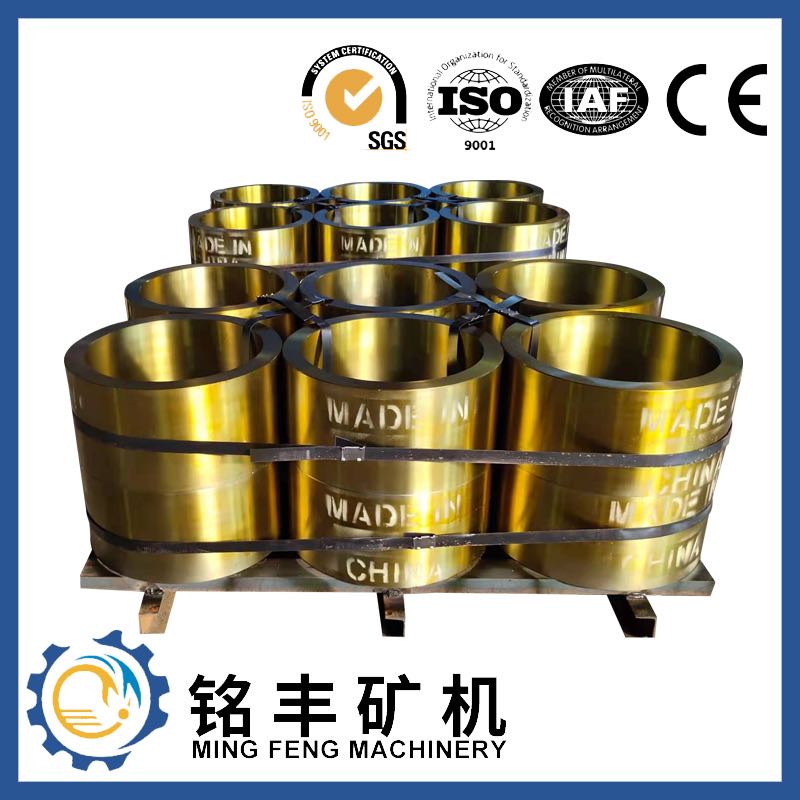

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We try for excellence, service the customers, hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Excellent quality Sandvik Blow Bar - PE-800×1060 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Spain, Palestine, Slovenia, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed