CSB160 Symons cone crusher

|

Model |

Dia.of cone |

Cavity |

Inch |

Discharge Opening Range |

Counter shaft |

Power |

Capacity |

Overall dimension |

Weight |

|

|

Opening |

Setting |

|||||||||

|

CSB160 |

1295 |

Fine type |

109 |

137 |

13-31 |

485 |

185 |

109-181 |

2800×2342×2668 |

27 |

|

Medium |

188 |

210 |

16-38 |

132-253 |

||||||

|

Coarse |

215 |

241 |

19-51 |

172-349 |

||||||

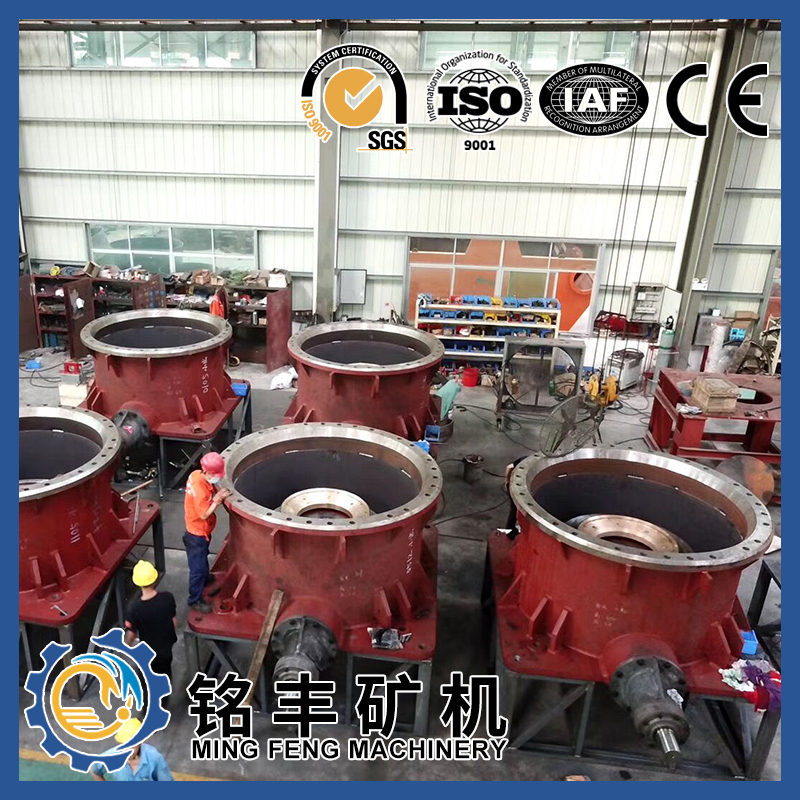

Description:

Symons cone crusher (spring cone crusher) can crush materials of above medium hardness. And it is widely used in metallurgy, building, hydropower, transportation, chemical industry, etc. When used with jaw crusher, it can be used as secondary, tertiary or quaternary crushing. Generally speaking, the standard type of Symons cone crusher is applied to medium crushing. The medium type is applied to fine crushing. The short head type is applied to coarse fine crushing. As casting steel technique is adopted, the machine has good rigidity and large high strength.

Working Principle:

Symons cone crusher crushes materials by the working surface between the concave and mantle. The movable cone of cone crusher is supported by spherical bearing and fixed on a hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearing. The movable cone and erect shaft are driven by the eccentric shaft sleeve together. The lower part of vertical shaft is installed in the eccentric sleeve. When the eccentric sleeve of cone crusher rotates, there is a conical surface lined out by the shaft. When the movable cone comes near the fixed cone, rocks are crushed into pieces, when the cone leaves, crushed materials is discharged from the discharge hole.

Features and Benefits:

1. high productivity

2.high quality

3. less downtime

4. easy maintenance and low cost

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed