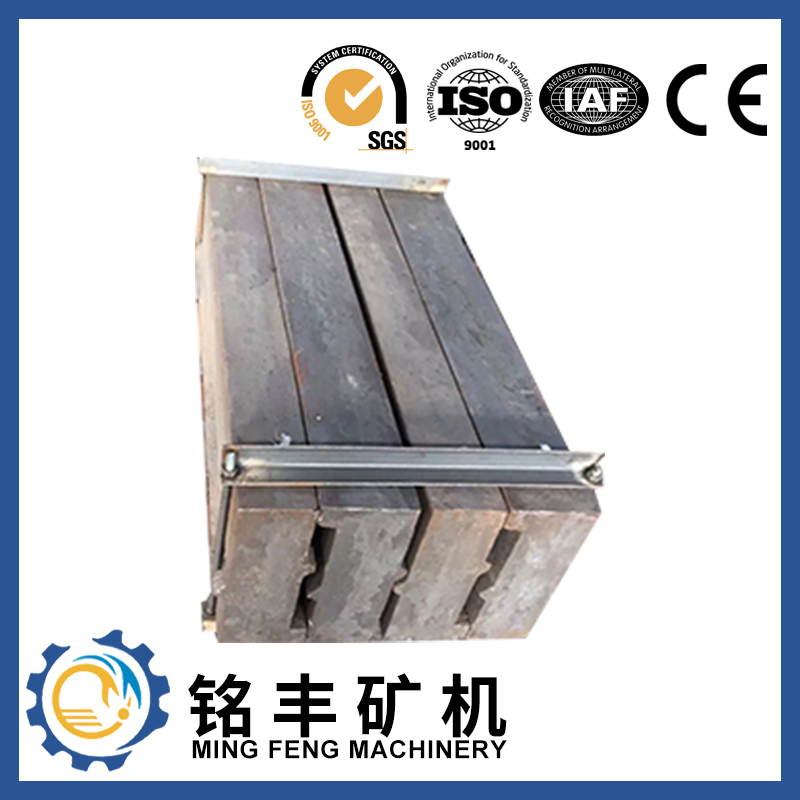

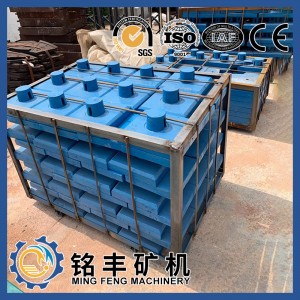

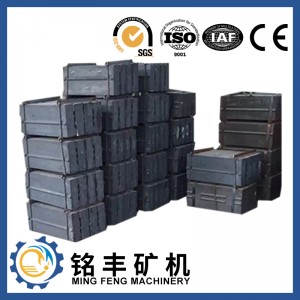

Cr26 high chrome PF-0807&PF-1310 impact crusher wear parts

Overview:

| Type | Bowl bar | ||

| Main Model |

PF series | PF1007,PF1010,PF1210,PF1214,PF1315,PF1320,PF1420,PF1620 | |

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Impact Crusher | Certification | ISO 9001:2008 |

| Hardness | HRC58 – HRC63 | Production Capability | More than 10000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Production Test | Hardness testing, metallographic testing, spectral analysis, mechanical properties and heat treatment. | ||

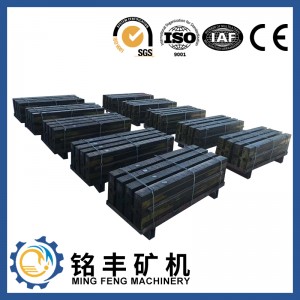

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

Blow bars are thick slabs of metal, typically some mixture of chrome, that are cast for the purpose of effectively breaking apart material like asphalt, concrete, limestone, etc. Often in sets of 3 or 4, blow bars are inserted into an impact crusher’s rotor where they are able to strike material needing processed.

As an important component of horizontal shaft impact crushers, blow bars come into direct contact with material and provide a powerful impact force. HSI crushers and their blow bars are designed to fracture material quickly, resulting in high production rates and reduced costs-per-ton when compare to other types of crushers.

MF is the wear parts store for all your plant equipment needs. All the wear parts provided by MF are backed with the ISO 9001 Certificate and shipped only after passing our quality control procedures. On the other hand, we also have had cooperation with many colleges to improve our technology and increase our products span-life.

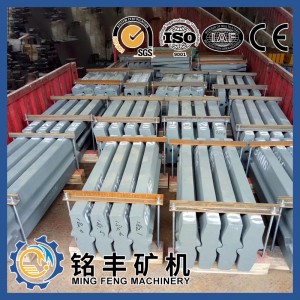

Production process:

1.Pattern Inspection

2.Moulding

3.Pouring

4.Heat Treatment

5.Raw Casting Inspection

6.Maching Inspection

7.Non Destructive Testing

8.Final Inspection

9.Delivery

Use: Quarry, Mining, Cement Aggregate, Recycling, Shredding, Demolition Fields. etc.

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Don’t have the model you need?

Don’t have the model you need?

We work with technical drawings for any non-standard products. If the order is for standard parts,you only have to provide us with the part number so we may define the parts of the order.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed