Competitive Price for L & T Mining Equipment - 2PG-900X500 roll crusher – MING FENG MACHINERY

Competitive Price for L & T Mining Equipment - 2PG-900X500 roll crusher – MING FENG MACHINERY Detail:

Roll Crusher Technical Data:

|

Specification |

Max Feed Edge |

Discharge Size |

Production |

Power |

Weight |

|

2PG-900X500 |

≤40 |

3–40 |

20-50 |

44 |

14000 |

Description:

The double-roller crusher is one of the crushers produced by our company for coarse/fine crushing. It is widely used in fields of cement making, chemical engineering, waterpower, metallurgy, construction, fire-proof material making, etc. It is suitable to deal with medium-hardness materials like limestone, pebble, clinker, coke, etc. The material to be crushed should have fracture strength less than 300MPa and humidity less than 35%.

Features:

1.High reduction ratio and productivity.

2.User-friendly.

3.Reliable operation.

4.Uniform-sized finished products.

5.Reduced noise level.

6.Environmentally friendly.

7.Sensitive over-load safety device.

8.Adjustable feed opening which is suitable to deal with materials with various fracture strengths.

9.Safety device which can protect the crusher: Normally, springs can bear the force used to crush the material. If something that can not be crushed is fed into the chamber, springs will be pressed. In the case, the discharge opening becomes larger and then the unknown material will be discharged. Afterwards, the rollers return to their normal positions under the force of the springs.

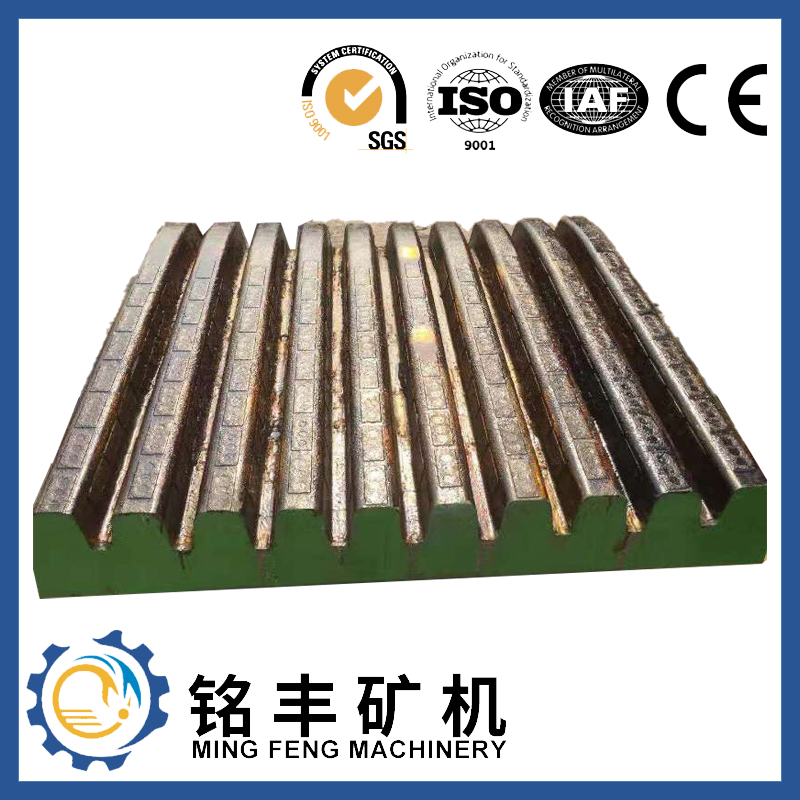

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for Competitive Price for L & T Mining Equipment - 2PG-900X500 roll crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Salt Lake City, Ukraine, Sacramento, To work with an excellent items manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed