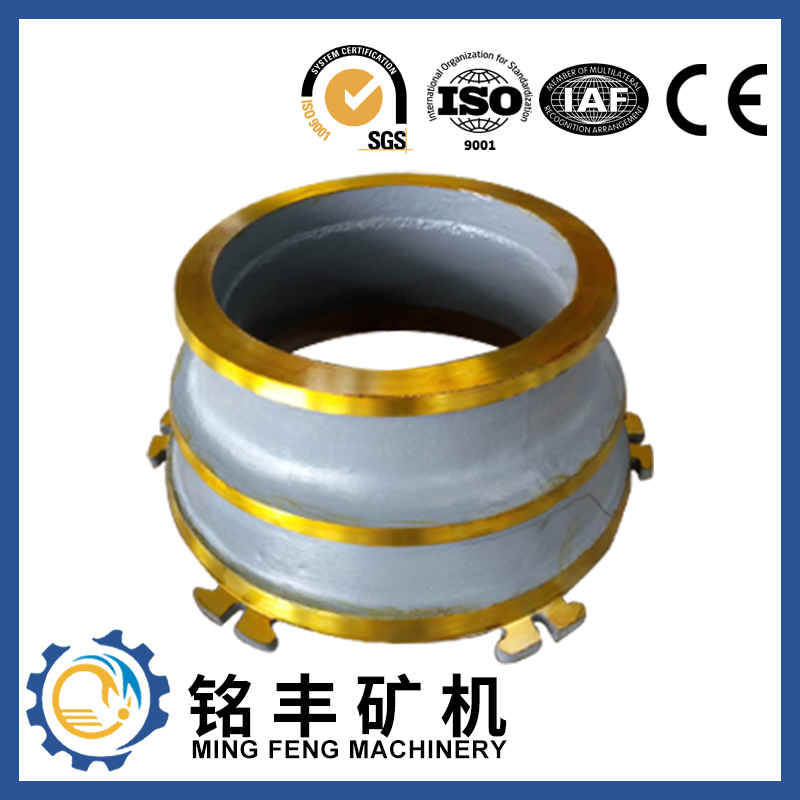

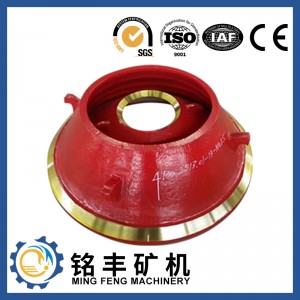

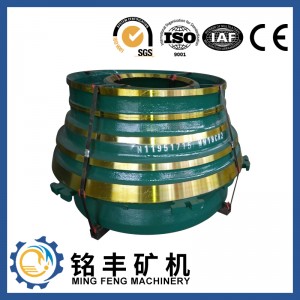

Common GP100S cone crusher liners

Cone crusher is widely applied in mining, metallurgy, construction, road building, chemical and phosphatic industry, and is suitable for hard and mid-hard rocks and ores.

Ming Feng is a professional OEM manufacturer, we produces manganese wear liners and accessories for most crushing brands including common, sandvick, Symons, common., Telsmith, Terex, Pegson, Lokomo, Kleeman, Hazemag and others. Most parts are available in 13%, 14%, 18% and 22% manganese alloys. Wear liners like mantle, bowl liner/concave for cone crushers, cheek plates and jaw plates for jaw crushers and blow bars for Horizontal Shaft Impactors are provided!

Overview:

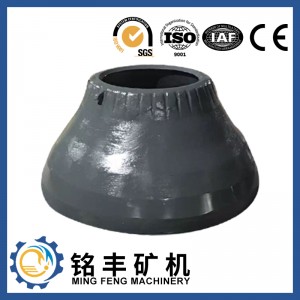

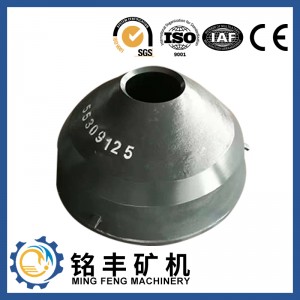

| Type | Bowl Liner, Concave Ring, Cone Liner,Mantle Liner | ||

| Main Model |

HP series | HP3 HP6 HP100 HP200 HP300 HP400 HP500 HP700 HP800 HP4 HP5 | |

| GP series | G8 G11 G12 G15 GP100S GP200S GP300S GP500S GP7 GP100 GP200 GP300 GP500 GP220 GP330 GP550 | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Cone Crusher | Certification | ISO 9001:2008 |

| Hardness | HB220~240 | Production Capability | More than 42000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

High Manganese series

Wear Parts for Mining equipment

Main application for high wear resistance use such as Jaw crusher plate, Cone crusher bowl liner, Impact crusher lining board, Ball mill liner and the chain links for Dredge ect.

High Manganess Casting Material Chemical Composition(%)

| Material Code | C | Mn | Si | Cr | P | S |

| ZGMn13Cr2 | C:0.9-1.3 | Mn:11.0-14.0 | Si:0.3-1.0 | Cr:1.5-2.5 | P:≤0.06 | S:≤0.04 |

| ZGMn18Cr2 | C:1.1-1.5 | Mn:16.5-19.0 | Si:≤0.8 | Cr:1.5-2.5 | P:≤0.07 | S:≤0.04 |

| ZGMn22Cr2 | C:1.1-1.4 | Mn:20-24 | Si:≤0.8 | Cr:1.5-2.5 | P:≤0.07 | S:≤0.04 |

Advantages:

1. Accurate dimensions, assure validity and suitability as per original parts number and drawing

2. Make your jaw crusher experience less downtime

3. More economical, save your cost 40-60%

4. Stronger wear resistance to reduce maintenance costs

5. Advanced manufacturing technology, produce strictly according to original process flow & original drawings.

Cone Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed