Chinese Professional Cj612 Wear Parts - 2PG-610X400 roll crusher – MING FENG MACHINERY

Chinese Professional Cj612 Wear Parts - 2PG-610X400 roll crusher – MING FENG MACHINERY Detail:

|

Specification |

Max Feed Edge |

Discharge Size |

Production |

Power |

Weight |

|

2PG-610X400 |

≤40 |

1–20 |

13-35 |

30 |

4500 |

Description:

A type of secondary or reduction crusher consisting of a heavy frame on which two rolls are mounted. These are driven so that they rotate toward one another. Rock fed in from above is nipped between the moving rolls, crushed, and discharged at the bottom.

It is widely used in fields of cement making, chemical engineering, waterpower, metallurgy, construction, fire-proof material making, etc. It is suitable to deal with medium-hardness materials like limestone, pebble, clinker, coke, etc. The material to be crushed should have fracture strength less than 300MPa and humidity less than 35%.

Working principle:

Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll. Shear and compression forces occur as the feed material is pulled between the crushing plate and/or crushing rolls.

Depending on the feed size, material is fed into the crushing chamber and encounters a single or a pair of rotating rolls. If a two-stage reduction is required, either a Triple or Quad Roll configuration can be used. In this scenario, the top stage of the crusher performs the primary reduction either by crushing the material between the roll and crushing plate or between a pair of rolls. The material is then fed directly between the two bottom-stage rolls for additional processing.

If a single-stage reduction is required, then depending on the feed-to-product-size ratio of reduction, either a Single or Double Roll Crusher can be selected. Regardless of the crusher type selected, Roll Crushers allow for the material to fracture along naturally occurring cleavage lines, which helps with minimizing fines generation.

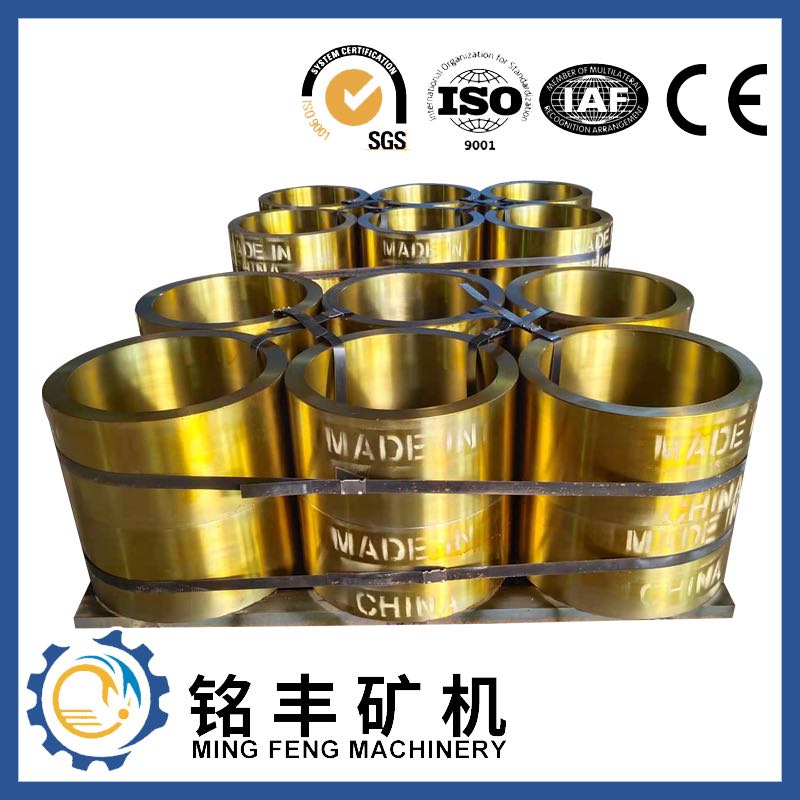

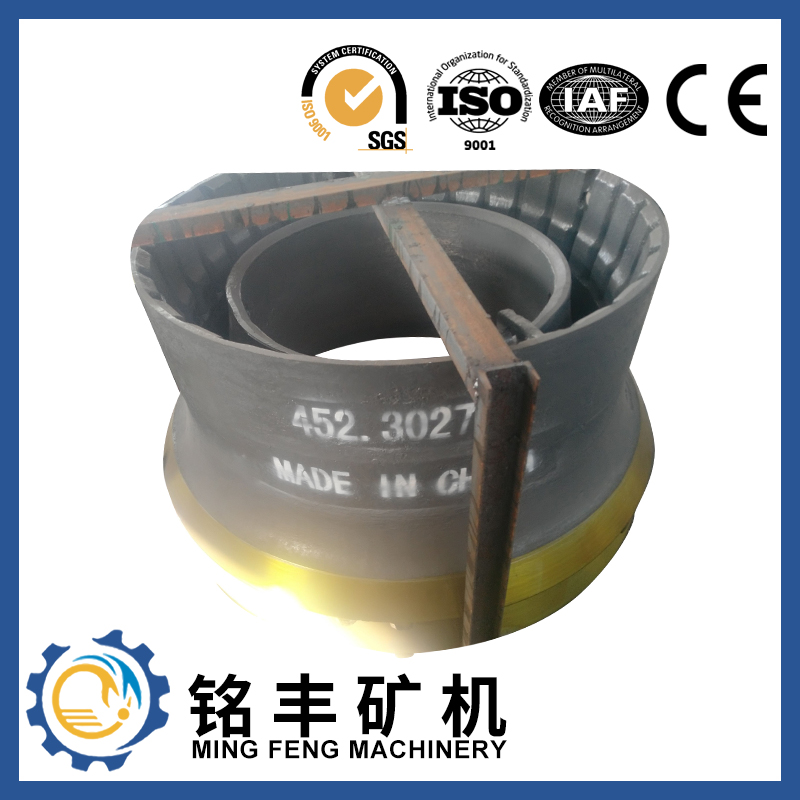

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for Chinese Professional Cj612 Wear Parts - 2PG-610X400 roll crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Ukraine, Italy, Luxemburg, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed