China Cheap price Pf 1007 Blow Bar - PE-600×900 jaw crusher – MING FENG MACHINERY

China Cheap price Pf 1007 Blow Bar - PE-600×900 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PE-600×900 |

600×900 |

500 |

50-120 |

250 |

55-75 |

65-160 |

15.5 |

Description:

It comprises the frame, the eccentric shaft, the grooved wheel, the flywheel, the mobile jaw, the side plate, the toggle plate, the captured spring, the fixed jaw plate and the mobile jaw plate, the safety device and the adjusting device, etc.

PE series jaw crushers are mainly used as primary crushers in aggregates production, mining operations and recycling applications. The product family consist of models of different sizes that are engineered to deliver the maximum productivity at the lowest operating costs.

Advantages:

1. High resistance to friction, abrasion and compression with longer operating life span.

2. Rigid one-piece fabricated base frame is reinforced for unmatched durability and strength

3.Energy saving and high yield, increasing the feeding capacity and output by 15-30%.

4. The machine adopts high-strength composite steel and high-strength forged crankshaft, making the equipment more robust and durable.

5. Simple structure, reliable working condition, low operating cost.

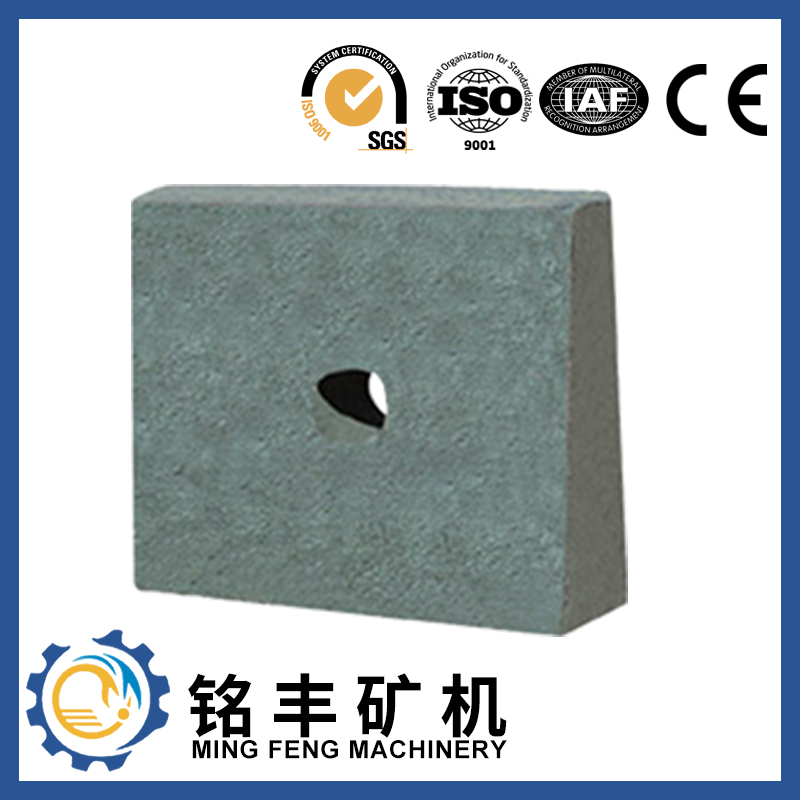

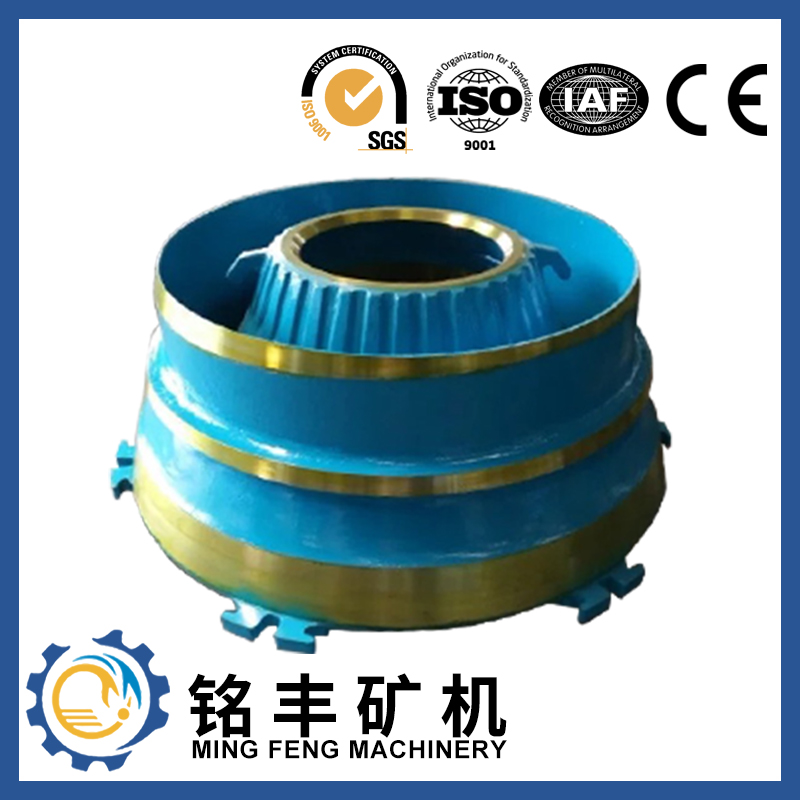

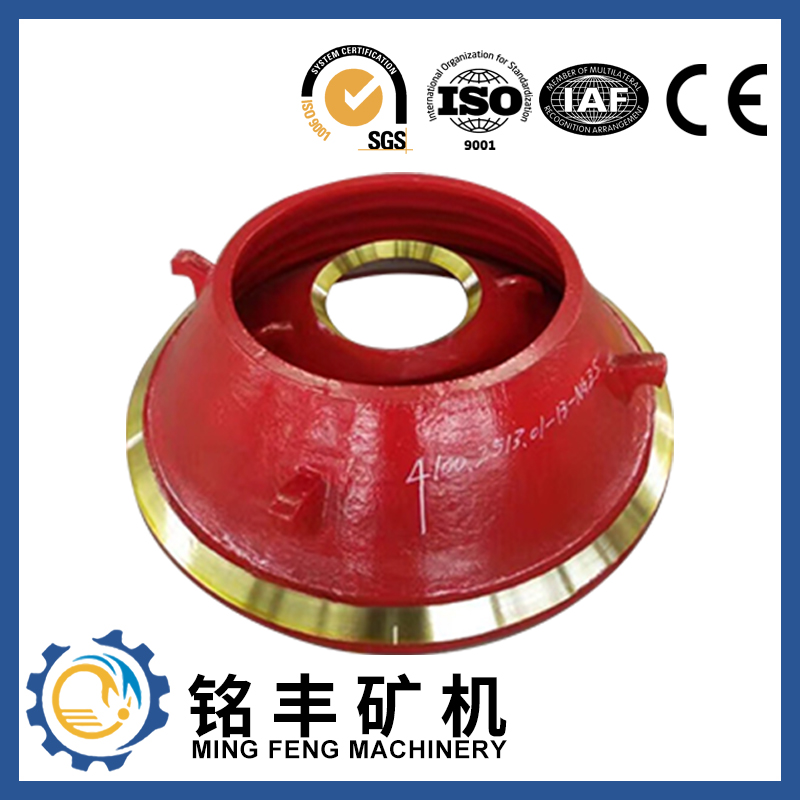

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for China Cheap price Pf 1007 Blow Bar - PE-600×900 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: Nairobi, Algeria, Hamburg, Our company upholds the spirit of innovation, harmony, team work and sharing, trails, pragmatic progress. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed