Big Discount Ci732 Hsi Scale Board - PE-1200×1500 jaw crusher – MING FENG MACHINERY

Big Discount Ci732 Hsi Scale Board - PE-1200×1500 jaw crusher – MING FENG MACHINERY Detail:

Jaw Crusher Technical Data:

|

Model |

Feed Opening Size |

Max Feed Edge |

Processing Capacity |

Eccentric Shaft Speed |

Motor Power |

Adjustment range |

Weight |

|

PE-1200×1500 |

1200×1500 |

1020 |

300-600 |

180 |

160 |

150-300 |

100.9 |

Description:

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

Jaw crushers are heavy duty machines and hence need to be robustly constructed. The outer frame is generally made of cast iron or steel. The jaws themselves are usually constructed from cast steel. They are fitted with replaceable liners which are made of manganese steel, or Ni-hard (a Ni-Cr alloyed cast iron). Jaw crushers are usually constructed in sections to ease the process transportation if they are to be taken underground for carrying out the operations.

Jaw crushers are classified on the basis of the position of the pivoting of the swing jaw

- Blake crusher-the swing jaw is fixed at the lower position

- Dodge crusher-the swing jaw is fixed at the upper position

- Universal crusher-the swing jaw is fixed at an intermediate position

Advantages:

1. Simple structure and easy maintenance.

2. Stable performance and low operating cost

3. Flexible discharge opening setting

4. High resistance to friction, abrasion and compression with longer operating life span.

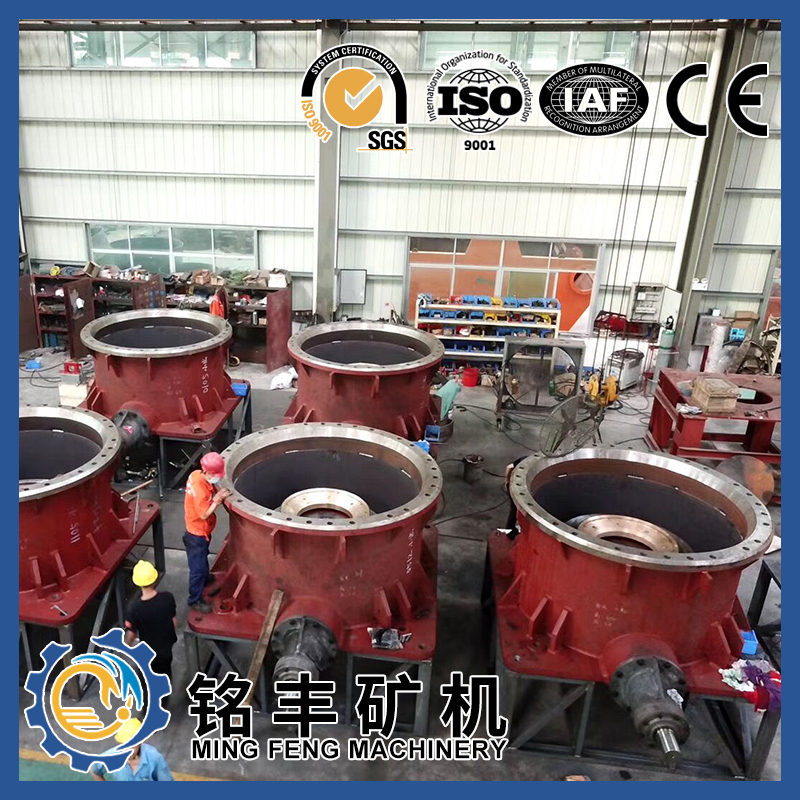

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth unification, determination, tolerance for Big Discount Ci732 Hsi Scale Board - PE-1200×1500 jaw crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: South Africa, Oman, Ukraine, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed