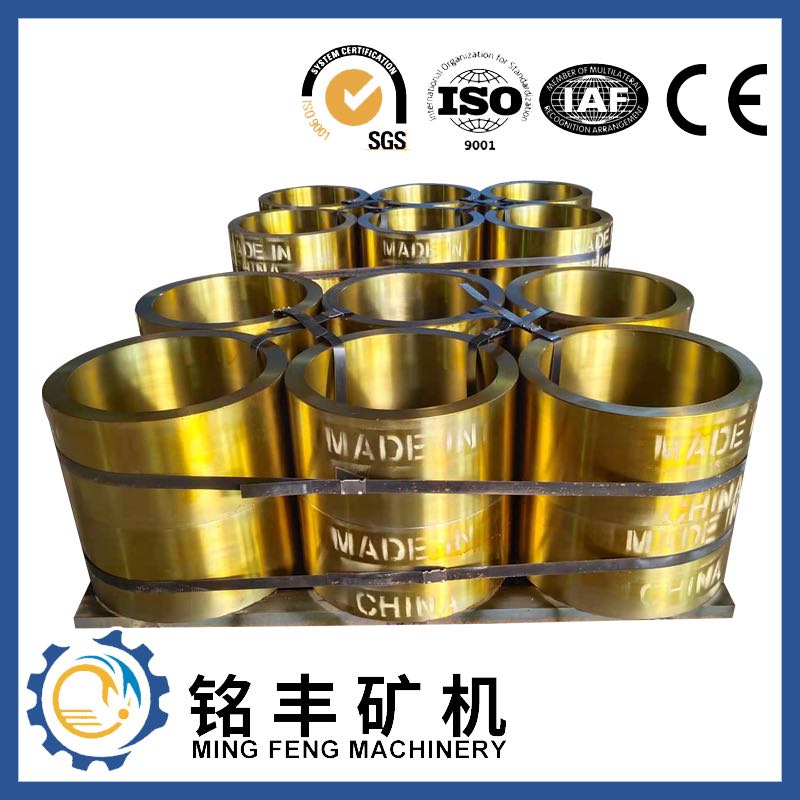

High chromium roller crusher wear parts

Overview:

| Type | tooth plate, Double Roller Crusherroller skin, high manganese steel roller skin | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Roller Crusher | Certification | ISO 9001:2008 |

| Hardness | HRC58 – HRC63 | Production Capability | More than 30000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Production Test | Hardness testing, metallographic testing, spectral analysis, mechanical properties and heat treatment. | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

For the roller crusher, the two opposite rotating rollers is used to realize the crushing and processing of the material. The double roller crusher is small in size, small in occupation, large in crushing ratio, low in noise and less in pollution. It is suitable for crusher quartz stone, limestone, pebbles, construction waste, coal and other materials for coarse and medium crushing. They are widely used in cement, chemical, sand, mining, building materials, coal mines and other industries.

Advantages:

1. Prietary work hardening alloys including Manganese for reduced maintenance and increased uptime.

2. Decreased downtimes and increased cost savings.

3. Better fit for quick and easy replacement.

4. Design improvements increase crusher efficiency and prevent premature erosion.

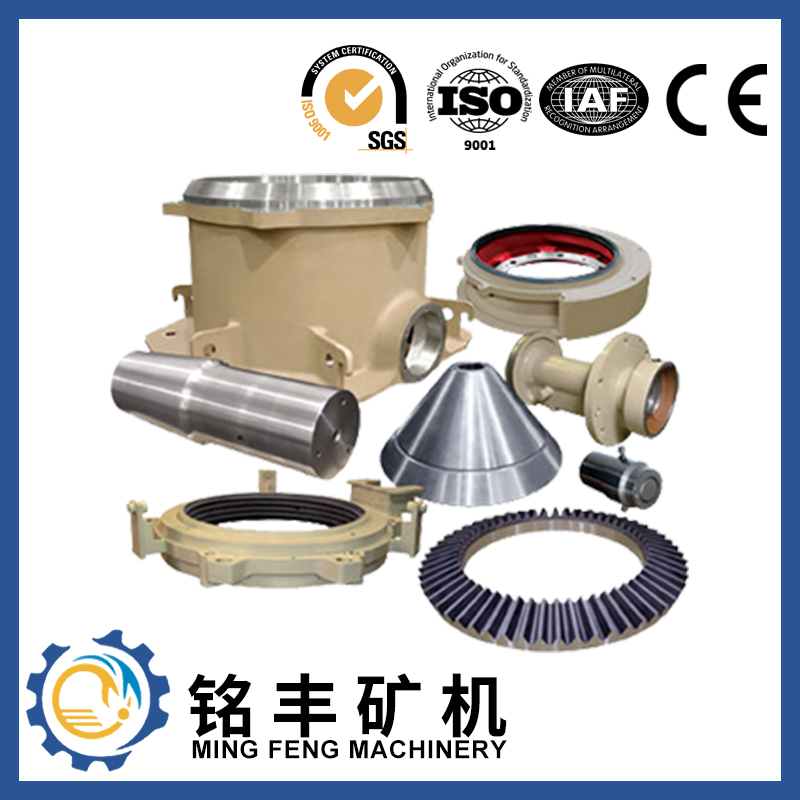

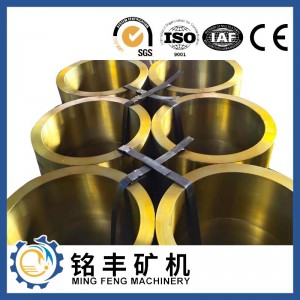

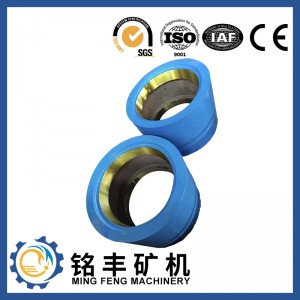

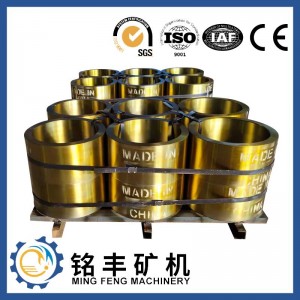

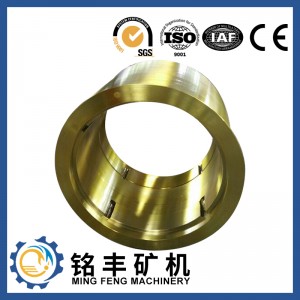

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Don’t have the model you need?

Don’t have the model you need?

We work with technical drawings for any non-standard products. If the order is for standard parts,you only have to provide us with the part number so we may define the parts of the order.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed